Preparation method of silica grinding and polishing agent

A technology of silica and polishing agent, which is applied in the preparation of grinding and polishing agents and in the field of preparation of silica grinding and polishing agents, which can solve the problems of low hardness of grinding and polishing agents, poor effect, complicated preparation process, etc., and achieve the effect of grinding and polishing The effect of improving and efficient grinding and polishing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

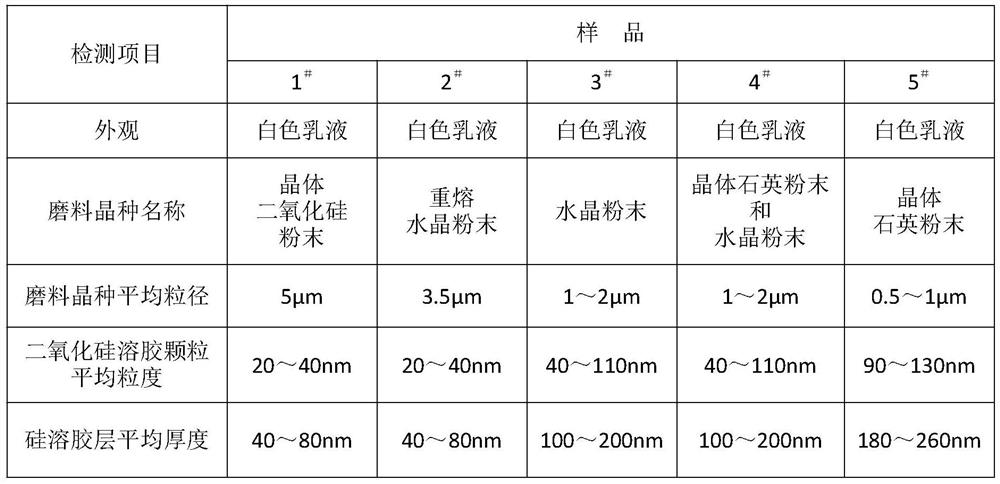

[0070] The preparation method of a kind of silica grinding and polishing agent provided in this embodiment specifically includes:

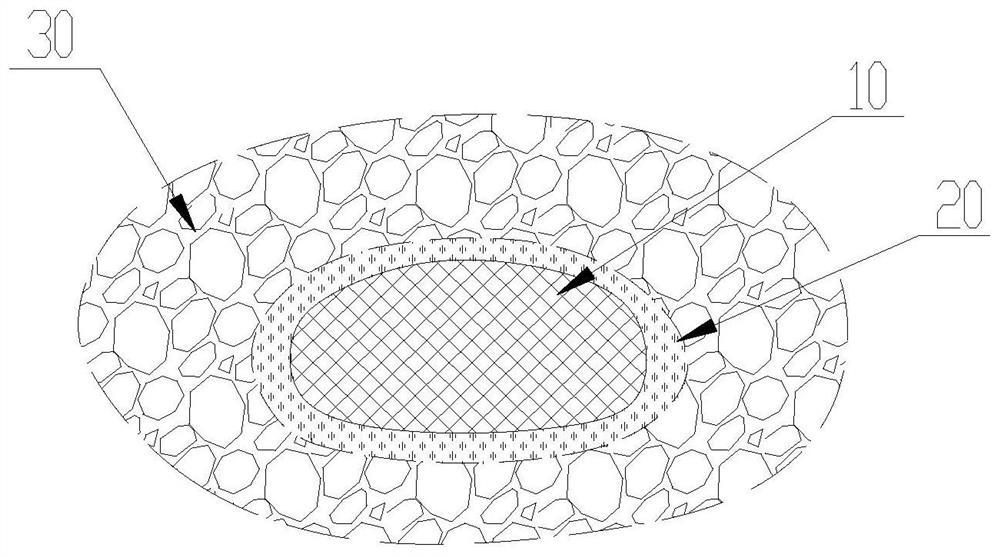

[0071] The preparation steps of abrasive seed crystals, the preparation steps of high-purity saturated silica sol solution, the preparation steps of abrasive crystal nuclei deposited with loose silica crystal particles, and the preparation steps of abrasive crystal nuclei mixed emulsion wrapped with silica sol layer, wherein :

[0072] The preparation step of abrasive seed crystal comprises:

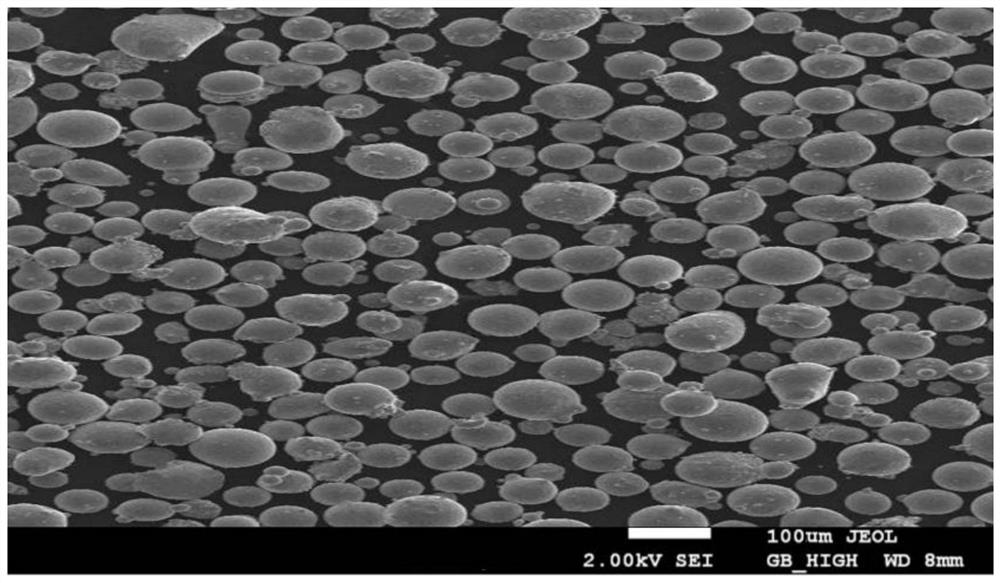

[0073] Put the rod-shaped or irregular polygonal abrasive powder in the ultrasonic grinding device, add water, then carry out wet ultra-fine grinding, and then obtain the initial particles of abrasive seed crystals with the desired particle size by washing and filtering;

[0074] Put the initial particles of abrasive seed crystals in an autoclave, add pure water, then add concentrated ammonia water as a catalyst, stir and heat, so that the initial particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com