An encircling zinc alloy rib bone plate, processing method and flexible forming device

A processing method and flexible forming technology, which is applied in the field of degradable metal medical implants and its preparation and processing, can solve the problems of optimization and improvement of difficult-to-synthesize bone plates, increase design and manufacturing costs, and achieve low internal tissue anisotropy, The effect of reducing medical expenses and reducing pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

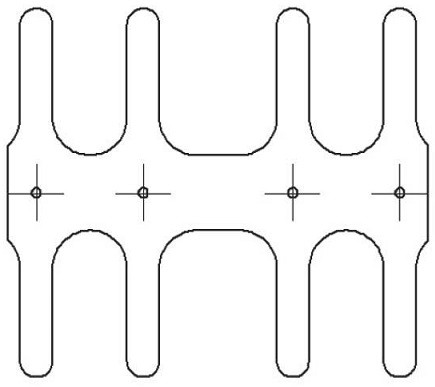

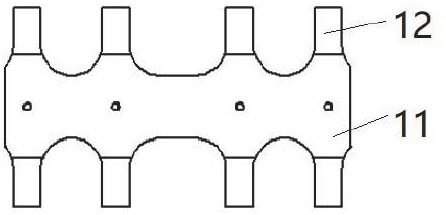

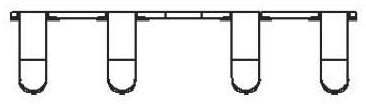

[0049] like figure 1 , Figure 2a , Figure 2b , Figure 2c and image 3 As shown, this embodiment provides an encircling zinc alloy rib bone plate, the bone plate is encircling, and the bone plate is made of medical degradable zinc alloy material. The encircling zinc alloy rib bone plate of this embodiment is made of medical degradable zinc alloy, the mechanical strength of the zinc alloy reaches the level of TA1 pure titanium, the degradation rate is moderate, and the corrosion is uniform, avoiding the existing inert metal rib bone plate The problem that the plate needs to be taken out by a second operation does not need to be taken out by a second operation, which significantly reduces the patient's pain and medical expenses.

[0050] The osteosynthesis plate in this embodiment includes a plate main body 11 and surrounding claws 12 connected to both sides of the plate main body 11 and symmetrically distributed. The plate main body 11 has a length of 20-200 mm, a width o...

Embodiment 2

[0053] like Figure 4 As shown, this embodiment provides a processing method for encircling zinc alloy rib bone plates. The processing method is used to manufacture encircling zinc alloy rib bone plates. The processing method includes casting, cross-hot rolling, rib Machining, flexible forming and surface treatment of bone plate blanks. In this example, the cross hot-temperature rolling process is used to process the bone plate, and the zinc alloy plate obtained by cross hot-temperature rolling has a low degree of anisotropy of the internal structure along the initial rolling direction and perpendicular to the initial rolling direction, and the degree of isotropy in mechanical properties High, the difference is less than 15%, the bending resistance of the prepared zinc alloy rib plate is better than that of TA1 industrial pure titanium rib plate.

[0054] like Figure 5 As shown, the processing method of the embracing zinc alloy rib bone plate of this embodiment may also inc...

Embodiment 3

[0056] Another example Figure 4 As shown, the present invention provides a method for processing an encircling zinc alloy rib bone plate, the processing method comprising:

[0057] S1, the casting, configure high-purity metal raw materials according to the alloy composition, put the raw materials into the smelting equipment for smelting, the melt refining temperature is 500~750°C, and after refining and holding for 5~15 minutes, pour the melt Put it into a mold supported by graphite, steel, etc., and cool to obtain a zinc alloy ingot. Preferably, the raw materials are put into smelting equipment such as a vacuum induction melting furnace.

[0058] S2. The cross hot rolling includes cross hot rolling and cross warm rolling;

[0059] The cross-hot rolling includes: the zinc alloy ingot is rolled at 210-380°C for at least 2 passes, the deformation in a single pass is 10-60%, and the rolling plate is rotated for 30-30% every 1-2 passes. Feed into the rolling mill at 90°, so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com