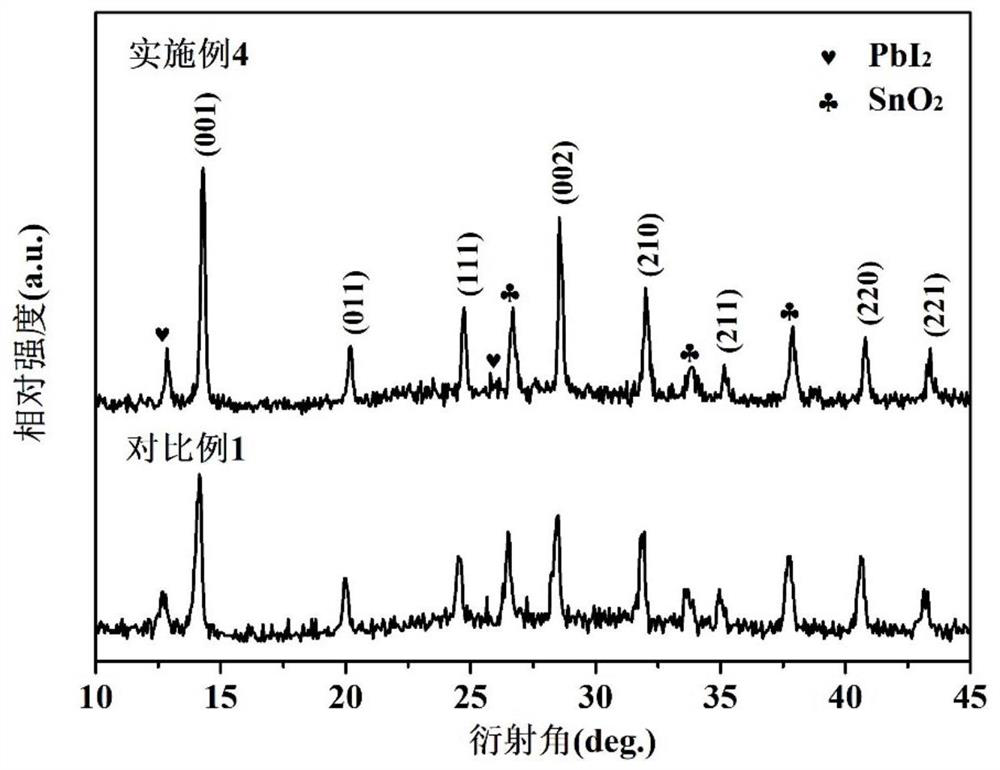

Perovskite light absorption layer film and surface defect passivation method thereof

A light absorbing layer, perovskite technology, applied in the field of solar cells, can solve problems such as affecting device efficiency, and achieve the effects of improving film quality, preventing erosion, and improving photoelectric conversion efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

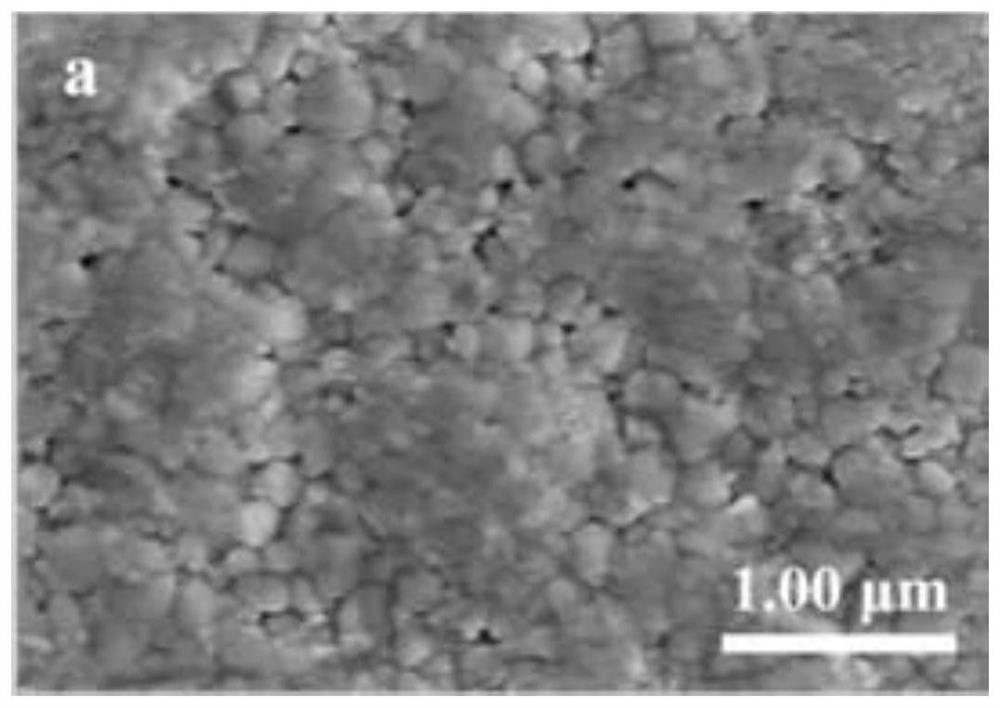

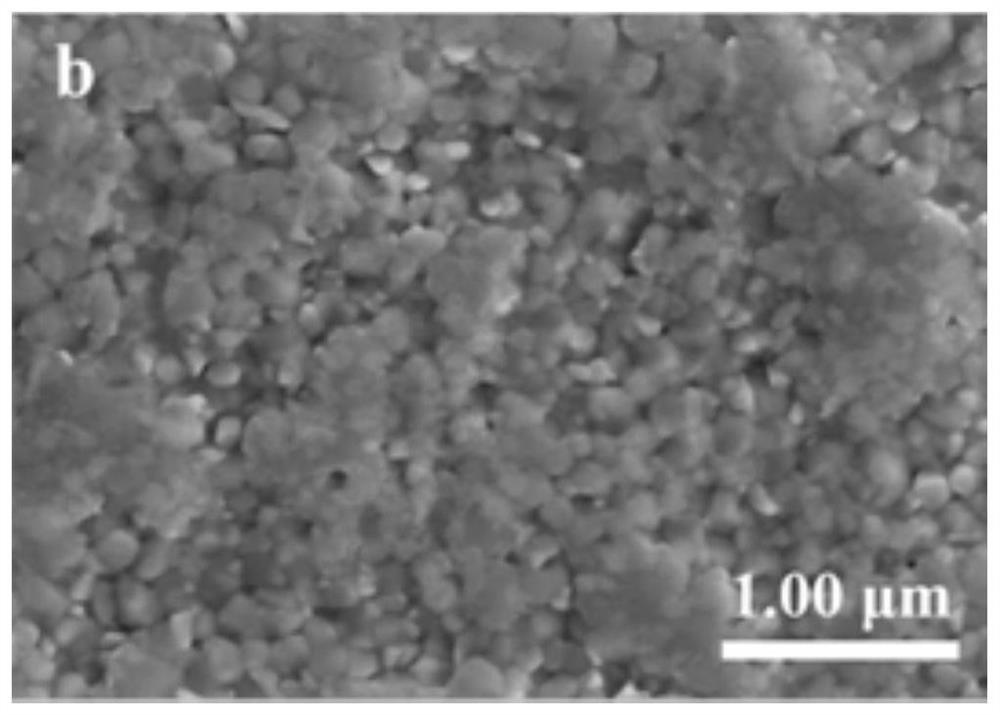

Image

Examples

Embodiment 1

[0044] (1) 0.507g PbI 2 , 0.172g FAI, 0.081g PbBr 2 , 0.023g MABr and 0.020g CsI were dissolved in 800mL N,N-dimethylformamide (DMF) and 200mL dimethylsulfoxide (DMSO) mixed solvent under stirring, and stirred for more than 4.5h to prepare a perovskite precursor solution .

[0045] (2) Add pyrrole to chlorobenzene to prepare a concentration of 3mmol L -1 additive solution.

[0046] (3) Evenly drop-coat the perovskite precursor solution on the FTO conductive glass substrate, start the spin coater, and start with 1000rpms -1 Acceleration to 1000rpm and rotate at low speed for 10s, then at 2000rpm s -1 The acceleration is accelerated to 5500rpm and rotated at a high speed for 25s to prepare a perovskite film; 2) the resulting surface additive solution is dripped on the surface of the perovskite film before the high-speed rotation of the spin coater stops; then After being dried in the atmosphere, it is dried at 100° C. and annealed for 60 minutes to obtain a surface-modified...

Embodiment 2

[0048] (1) 0.507g PbI 2 , 0.172g FAI, 0.081g PbBr 2 , 0.023g MABr and 0.020g CsI were dissolved in 800mL N,N-dimethylformamide (DMF) and 200mL dimethylsulfoxide (DMSO) mixed solvent under stirring, and stirred for more than 4.5h to prepare a perovskite precursor solution .

[0049] (2) Add pyrrole to chlorobenzene to prepare a concentration of 6mmol L -1 additive solution.

[0050] (3) Evenly drop-coat the perovskite precursor solution on the FTO conductive glass substrate, start the spin coater, and start with 1000rpms -1 Acceleration to 1000rpm and rotate at low speed for 10s, then at 2000rpm s -1 The acceleration is accelerated to 5500rpm and rotated at a high speed for 25s to prepare a perovskite film; 2) the resulting surface additive solution is dripped on the surface of the perovskite film before the high-speed rotation of the spin coater stops; then After being dried in the atmosphere, it is dried at 100° C. and annealed for 60 minutes to obtain a surface-modified...

Embodiment 3

[0052] (1) 0.507g PbI 2 , 0.172g FAI, 0.081g PbBr 2 , 0.023g MABr and 0.020g CsI were dissolved in 800mL N,N-dimethylformamide (DMF) and 200mL dimethyl sulfoxide (DMSO) mixed solvent under stirring, and stirred for more than 4.5h to prepare a perovskite precursor solution.

[0053] (2) Add pyrrole to chlorobenzene to prepare a concentration of 9mmol L -1 additive solution.

[0054] (3) Evenly drop-coat the perovskite precursor solution on the FTO conductive glass substrate, start the spin coater, and start with 1000rpms -1 Acceleration to 1000rpm and rotate at low speed for 10s, then at 2000rpm s -1 The acceleration is accelerated to 5500rpm and rotated at a high speed for 25s to prepare a perovskite film; 2) the resulting surface additive solution is dripped on the surface of the perovskite film before the high-speed rotation of the spin coater stops; then After being dried in the atmosphere, it is dried at 100° C. and annealed for 60 minutes to obtain a surface-modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com