Corrosion-resistant large-diameter bimetal metallurgy composite pipe

A large-diameter, bi-metal technology, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems that composite pipes cannot guarantee long-term use, difficult assembly and welding, general corrosion resistance, etc., to increase the scope of use , Convenient installation and combination, the effect of preventing internal water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

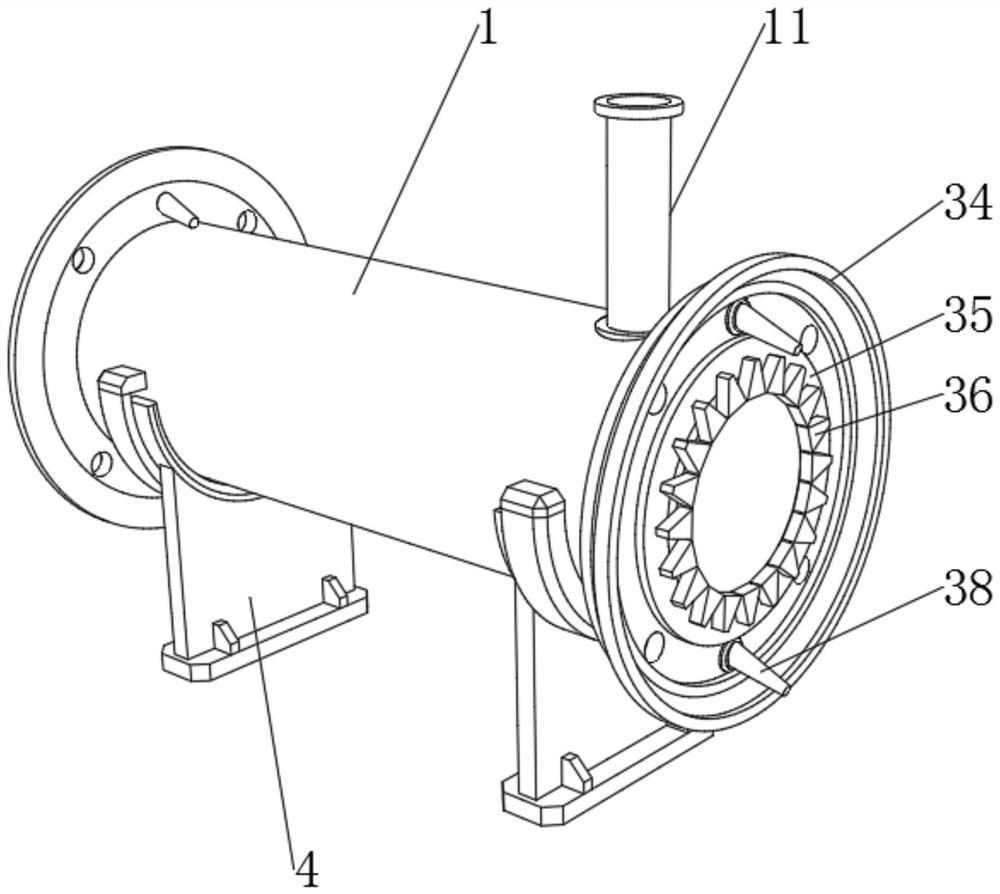

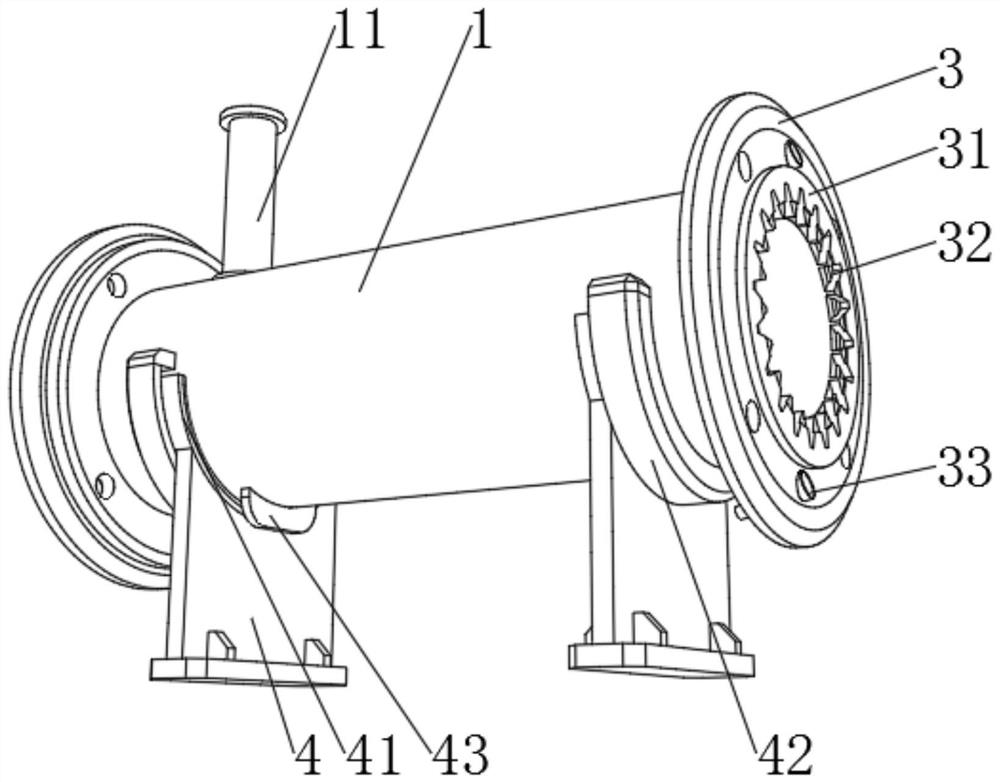

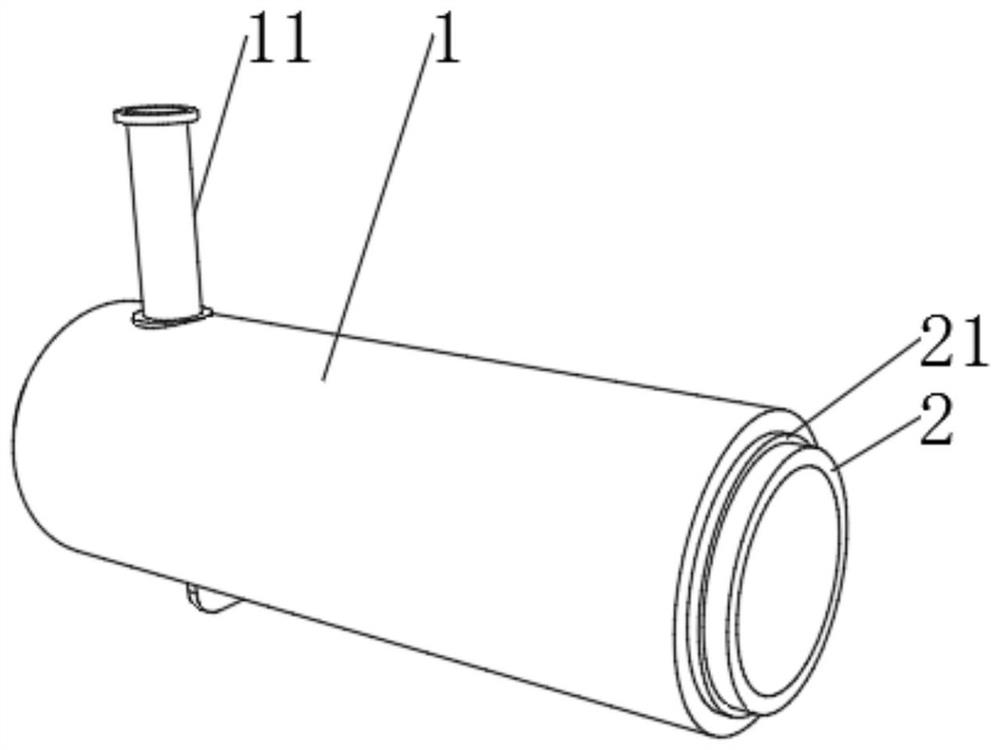

[0023] Such as Figure 1-3 As shown, the present invention provides a technical solution: a corrosion-resistant large-diameter bimetallic metallurgical composite pipe, including a composite pipe 1 and a secondary pipe 11, the top of the composite pipe 1 is fixedly connected with the secondary pipe 11, and the inner wall of the composite pipe 1 is fixed A fluorine-lined pipe 2 is connected, and a corrosion-resistant sealing ring 21 is fixedly connected between the inner wall of the composite pipe 1 and the outer wall of the fluorine-lined pipe 2. One end of the composite pipe 1 is fixedly installed with a butt plate 3, and one end of the composite pipe 1 is provided with a pair of The connecting plate 31, the other end of the composite pipe 1 is fixedly equipped with a cover plate 34, the other end of the composite pipe 1 is provided with a counter-insert plate 35, and the bottom of the composite pipe 1 is symmetrically and movablely installed with two groups of supporting frame...

Embodiment 2

[0026] Such as Figure 1-3 As shown, the side of the docking plate 31 is evenly provided with a docking groove 32, the side of the docking plate 35 is evenly provided with a mating block 36, the side of the docking plate 3 is provided with a docking hole 33, and the side of the cover plate 34 is fixedly installed with mating blocks. The column 38 and the top of the support frame plate 4 are fixedly connected with an installation bar 41, and the installation bar 41 is movably installed on the inside of the installation groove 42, and the bottom of the composite pipe 1 is symmetrically fixed with a baffle 43, and the baffle 43 is fixedly installed in the installation groove 42 The sides of the butt plate 3 and the cover plate 34 are provided with bolt fixing holes, the bottom of the support frame plate 4 is fixedly equipped with a support plate, and a side support plate is fixedly connected between the support frame plate 4 and the support plate.

[0027] In this embodiment, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com