High-energy silver cluster-based assembly ignition material and preparation method thereof

A silver-cluster-based, silver-cluster technology, applied in the intersection of nanoclusters and coordination chemistry, can solve problems such as difficulty in igniting performance and high energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

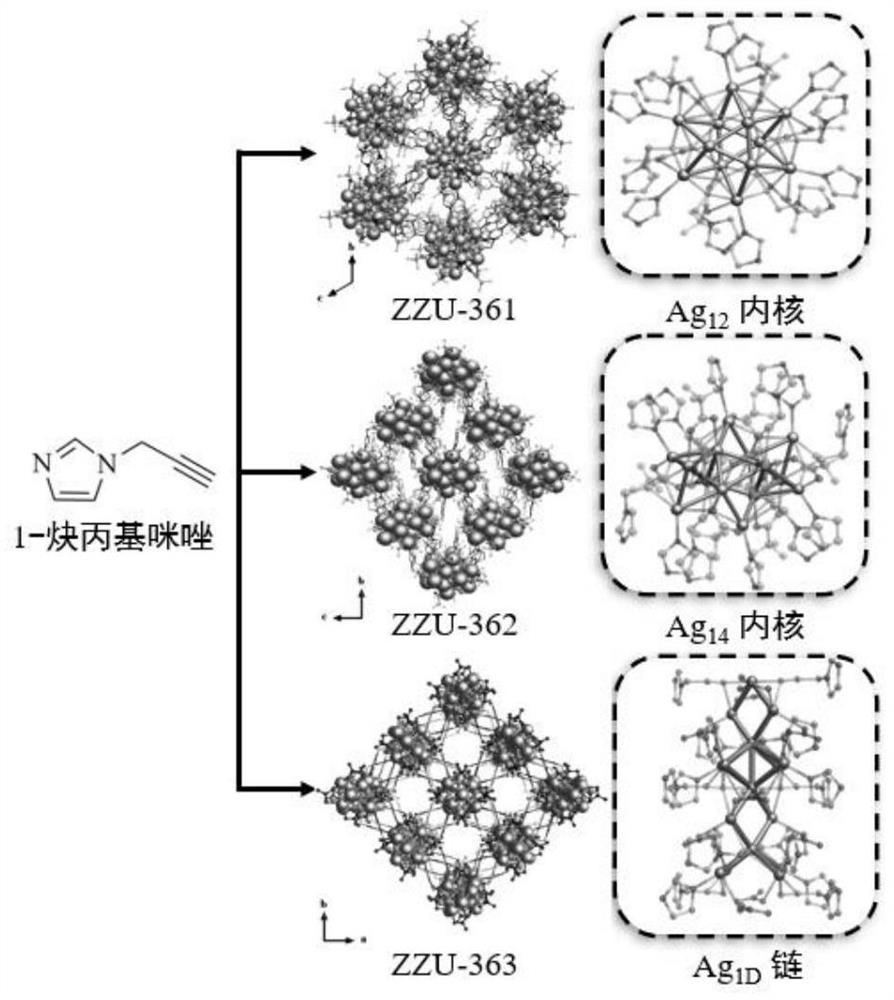

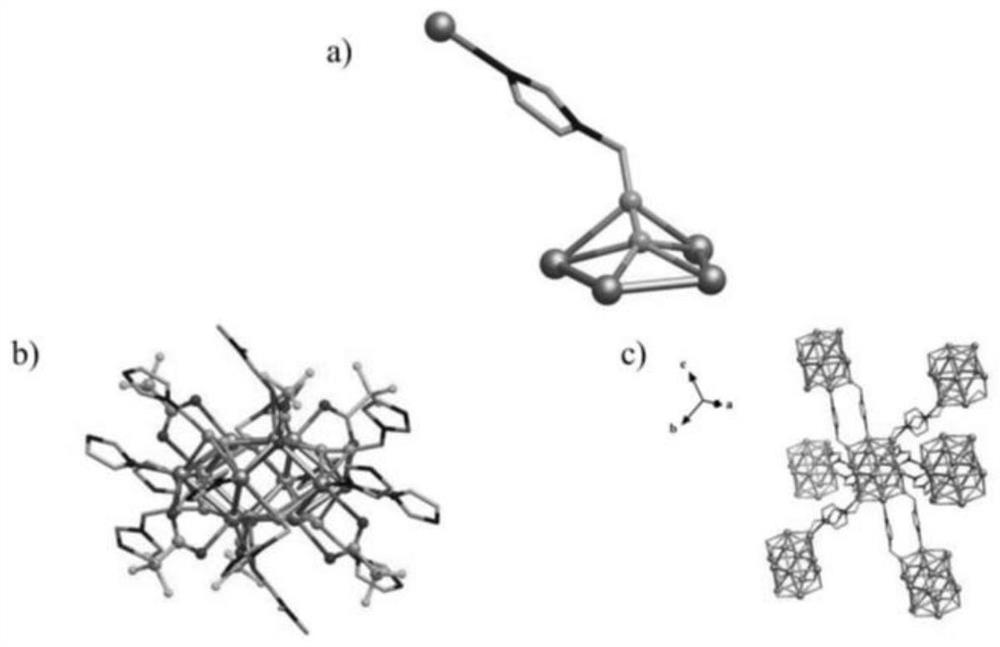

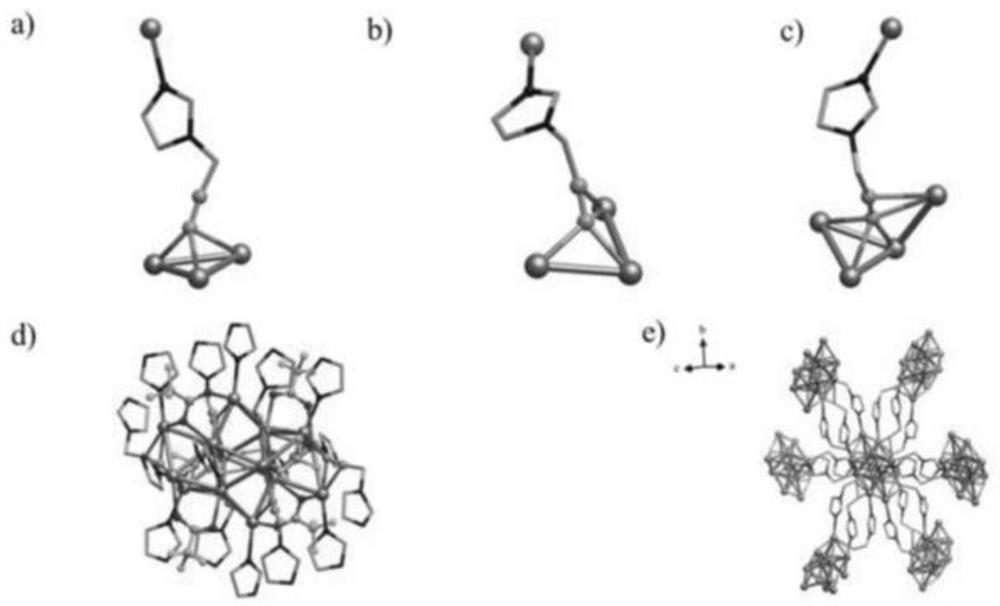

[0027] Example 1: Synthesis of ZZU-361, ZZU-362, ZZU-363 of the present invention

[0028] (1) Synthesis of silver propargyl imidazole: silver oxide (Ag 2 O) be dissolved in ammoniacal liquor under ice-water bath condition, stir, until dissolve completely, then slowly add the 1-propargyl imidazole dissolved in ethanol dropwise in silver oxide ammonia aqueous solution, stir reaction, after reaction finishes, suction filtration , washed the precipitate with ethanol and ether to obtain silver propargyl imidazole. The molar ratio of silver oxide / ammonia / propargyl imidazole is 1:2:2.

[0029] (2) ZZU-361: with dimethylformamide (DMF) / methanol (CH 3 OH) (v / v=2 / 1, 6mL) mixed with CF 3Dissolve silver propargyl imidazole (11.0 mg, 0.05 mmol) and silver trifluoroacetate (11 mg, 0.05 mmol) in COOH (10 μL) solution, stir overnight, filter, and evaporate the clear liquid at room temperature for several days to obtain a colorless transparent bulk crystals.

[0030] ZZU-362: Similar to ...

Embodiment 2

[0040] Structural stability test of ZZU-361, ZZU-362, and ZZU-363: The above materials were placed in different humidity environments for three days. The PXRD test showed that they could well maintain the structural stability.

[0041] Ignition performance test of ZZU-361, ZZU-362, ZZU-363: using a standard ignition test experiment, select a certain amount of ignition material (about 15mg) in a 5mL glass container, place it in a room temperature environment, use a pipette Pipette a drop (approximately 30 μL) of WFNA, from a fixed height, into the reaction vessel. The moment when the oxidant contacts the material is recorded as the reaction zero point, until the first flame appears in the reaction vessel, and the intermediate interval is recorded as the ignition delay time. From the experimental results, it can be known that the ignition delay time of the material ZZU-361 The ignition delay time of material ZZU-362 is 59ms, while that of ZZU-363 is 26ms. From the point of view...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com