High-voltage LED chip with microstructural antireflection film

A technology of LED chips and anti-reflection coatings, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., to achieve the effects of increasing output energy, improving light output efficiency, and reducing reflection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples, but the implementation and protection of the present invention are not limited thereto.

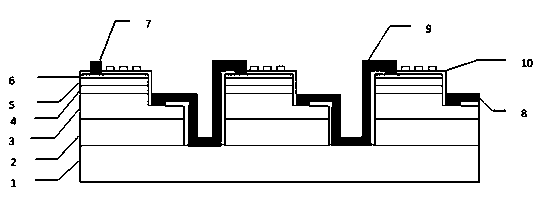

[0024] See figure 1 , a high-voltage LED chip with a microstructure anti-reflection film, including a plurality of light-emitting units, each light-emitting unit sequentially includes a gem substrate 1, a buffer layer 2, an N-type layer 3, a quantum well layer 4, a P-type Layer 5 and ITO layer 6, each light-emitting unit also includes an electrode 7 on the P-type layer and an electrode 8 on the N-type layer, and the electrodes between adjacent light-emitting units are connected by a connecting bridge 9, and each light-emitting unit also includes a covering On the anti-reflection film 10 on the ITO layer, the top surface of the anti-reflection film above the ITO layer 6 has a cylindrical microstructure.

[0025] Generally, the main lumines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com