Maitake soy sauce, maitake particle soy sauce and preparation methods of maitake soy sauce and maitake particle soy sauce

A technology of maitake and soy sauce, applied in the field of maitake granule soy sauce and its preparation, and the field of maitake soy sauce, which can solve the problems of easy moisture absorption, waste of resources, and difficulty in instant dissolution, etc., to improve the oil yield of sauce fermented grains, improve production technology, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

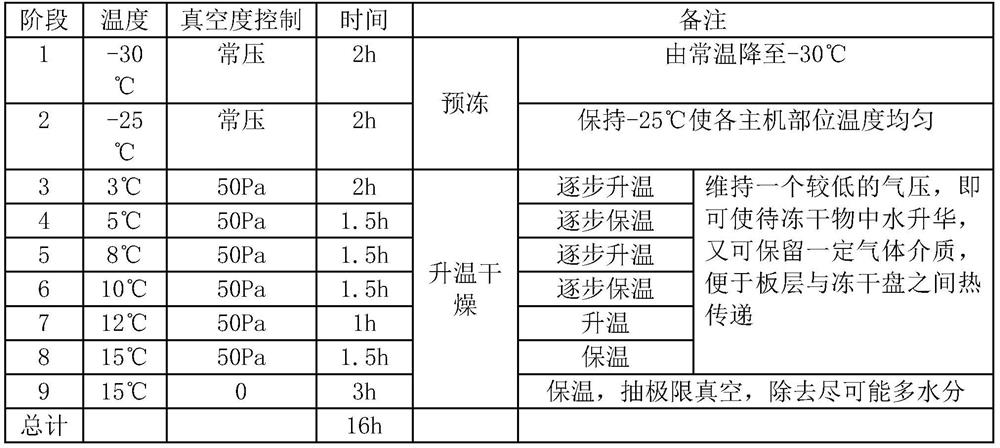

Method used

Image

Examples

Embodiment 1

[0047] A kind of maitake soy sauce is characterized in that the proportioning is carried out according to the following weight percentages: 60% of maitake, 30% of soybean and 10% of wheat bran.

[0048] A preparation method of maitake soy sauce, comprising the following steps:

[0049] S1, pretreatment, first cut the maitake mushroom into pieces to obtain maitake granules, then fry the maitake granules, soybeans, and wheat bran separately, and pulverize the fried maitake granules, soybeans, and wheat bran respectively to obtain small particles shape;

[0050] 1) Stir-frying of raw materials, use a mushroom cutter to cut the maitake into 2cm small pieces to obtain maitake granules, then use an air dryer to dry the water to below 30%, and finally move the maitake granules into the rotating frying pan Stir-frying in the material machine, the frying time is 30 minutes, the frying temperature is 70°C, the moisture content of the fried maitake granules is 13%, the color is yellowis...

Embodiment 2

[0079] A kind of maitake soy sauce is characterized in that the proportioning is carried out according to the following weight percentages: 50% of maitake, 45% of soybean and 5% of wheat bran.

[0080] A preparation method of maitake soy sauce, comprising the following steps:

[0081] S1, pretreatment, first cut the maitake mushroom into pieces to obtain maitake granules, then fry the maitake granules, soybeans, and wheat bran separately, and pulverize the fried maitake granules, soybeans, and wheat bran respectively to obtain small particles shape;

[0082]1) Stir-frying of raw materials, use a mushroom cutter to cut the maitake into 3cm small pieces to obtain maitake particles, then use an air dryer to dry the water to below 30%, and finally move the maitake particles into the rotating frying pan Stir-fried in the material machine, the frying time is 25 minutes, the frying temperature is 65°C, the moisture content of the fried maitake granules is 13%, the color is yellowish...

Embodiment 3

[0111] A kind of maitake soy sauce is characterized in that the proportioning is carried out according to the following percentages by weight: 40% of maitake, 35% of soybean and 25% of wheat bran.

[0112] A preparation method of maitake soy sauce, comprising the following steps:

[0113] S1, pretreatment, first cut the maitake mushroom into pieces to obtain maitake granules, then fry the maitake granules, soybeans, and wheat bran separately, and pulverize the fried maitake granules, soybeans, and wheat bran respectively to obtain small particles shape;

[0114] 1) Stir-frying of raw materials, use a mushroom cutter to cut the maitake into 2cm small pieces to obtain maitake granules, then use an air dryer to dry the water to below 30%, and finally move the maitake granules into the rotating frying pan Stir-fried in the material machine, the frying time is 20 minutes, the frying temperature is 65°C, the moisture content of the fried maitake granules is 13%, the color is yellow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com