Weathering resistant steel surface stabilizing treatment agent suitable for industrial atmospheric environment and treatment method

A stabilizing treatment agent and stabilizing treatment technology, applied in the field of steel anticorrosion, can solve the problems of immature weathering steel stabilization technology, late start, no relevant standards for coating-free technology, etc. , the effect of shortening the stabilization period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

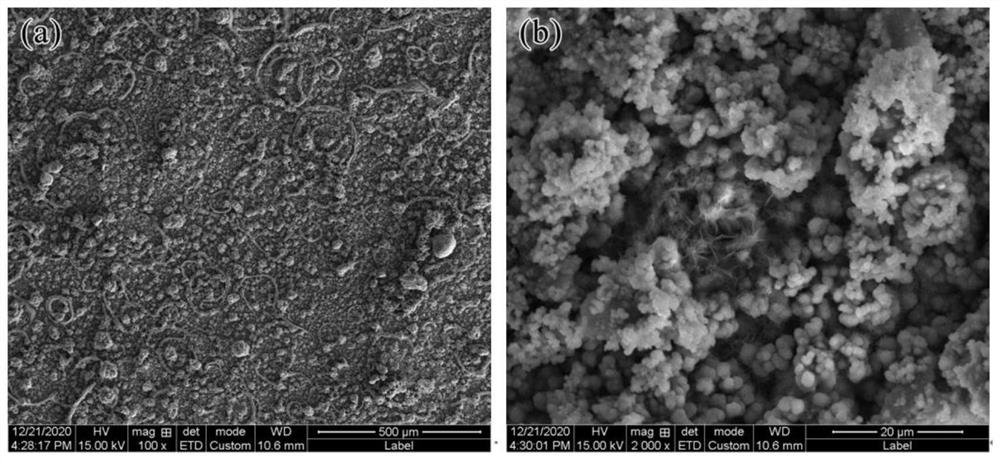

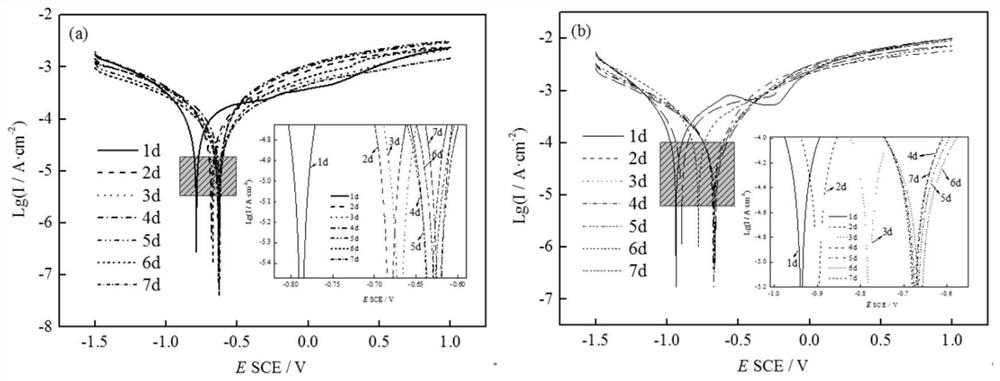

[0040] A method for stabilizing the rust layer of bridge weathering steel suitable for industrial atmospheric environments, comprising the steps of:

[0041] S1. Use Q345qNH bridge weathering steel, cut it into 10mm×10mm×8mm size by wire cutting, use sandblasting machine to remove the hot-rolled scale on the weathering steel surface, and then use 600 mesh and 800 mesh sandpaper to polish the weathering steel sample in turn The surface is smooth and flat, scrubbed with alcohol, degreased with acetone, and then dried in a vacuum oven;

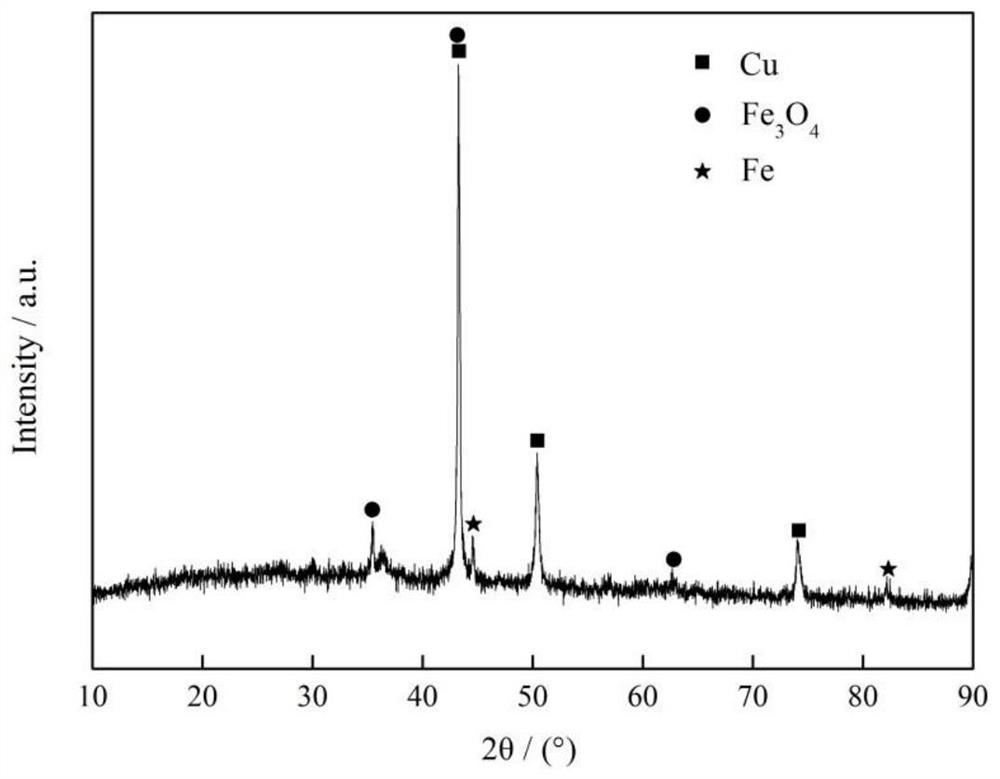

[0042] S2, prepare 100g weathering steel surface rust layer stabilization treatment agent (stabilizer): take 1.0g of CuSO respectively 4 , 3.0g of Cr 2 (SO 4 ) 3 , 0.6g NaHSO 3 and 0.1 g of Fe 3 o 4 , mixed with 95.3g deionized water and then poured into the container to obtain a weathering steel surface rust layer stabilizing treatment agent (stabilizer);

[0043] S3. Immerse the weathering steel with the surface scale removed in the prep...

Embodiment 2

[0058] A method for stabilizing the rust layer of bridge weathering steel suitable for industrial atmospheric environments, comprising the steps of:

[0059] S1. Use Q345qNH bridge weathering steel, cut it into 10mm×10mm×8mm size by wire cutting, use sandblasting machine to remove the hot-rolled scale on the weathering steel surface, and then use 600 mesh and 800 mesh sandpaper to polish the weathering steel sample in turn The surface is smooth and flat, scrubbed with alcohol, degreased with acetone, and then dried in a vacuum oven;

[0060] S2, prepare 100g weathering steel surface rust layer stabilization treatment agent (stabilizer): take 0.8g CuSO respectively 4 , 3.2g of Cr 2 (SO 4 ) 3 , 0.7g of NaHSO 3 and 0.08g of Fe 3 o 4 , mixed with 95.22g deionized water and then poured into the container to obtain a weathering steel surface rust layer stabilization treatment agent (stabilizer);

[0061] S3. Immerse the weathering steel with the surface scale removed in the p...

Embodiment 3

[0064] A method for stabilizing the rust layer of bridge weathering steel suitable for industrial atmospheric environments, comprising the steps of:

[0065] S1. Use Q345qNH bridge weathering steel, cut it into 10mm×10mm×8mm size by wire cutting, use sandblasting machine to remove the hot-rolled scale on the weathering steel surface, and then use 600 mesh and 800 mesh sandpaper to polish the weathering steel sample in turn The surface is smooth and flat, scrubbed with alcohol, degreased with acetone, and then dried in a vacuum oven;

[0066] S2, prepare 100g weathering steel surface rust layer stabilization treatment agent (stabilizer): take 1.2g of CuSO respectively 4 , 2.8g of Cr 2 (SO4 ) 3 , 0.5g NaHSO 3 and 0.1 g of Fe 3 o 4 , mixed with 95.4g deionized water and then poured into the container to obtain a weathering steel surface rust layer stabilizing treatment agent (stabilizer);

[0067] S3. Immerse the weathering steel with the surface scale removed in the prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com