Preparation method for synthesizing vanadium-nitrogen alloy from vanadium slag

A vanadium-nitrogen alloy and vanadium-slag technology is applied in the field of vanadium-slag synthesis of vanadium-nitrogen alloys, and can solve the problems of difficulty in the synthesis of vanadium-nitrogen alloys, low processing efficiency, inconvenience in the stability and durability of vanadium-nitrogen alloys, and the like. Achieve the effect of improving preparation efficiency, improving durability and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a technical solution: a method for preparing a vanadium-nitrogen alloy synthesized from vanadium slag, comprising the following steps:

[0021] S1. According to the design standard, weigh the vanadium slag, iron nitride and magnesium nitride, wash the vanadium slag with clean water, and dry it with a dryer after washing. The dried vanadium slag and nitriding Iron and magnesium nitride are mixed, and after mixing, crushing is carried out, and after crushing, a 30-50 mesh screen is used for screening, and the vanadium slag that has not been successfully screened is continued to be crushed, and after crushing, continue to be screened to obtain No. 1 mixed material;

[0022] S2. Weigh the reducing agent, loosening agent, and aluminum powder, mix and stir the reducing agent and the mixture obtained in S1, the stirring time is 20-50min, the stirring speed is 100-250r / min, after the mixing is completed, Then add loosening agent and aluminum powder, conti...

Embodiment 1

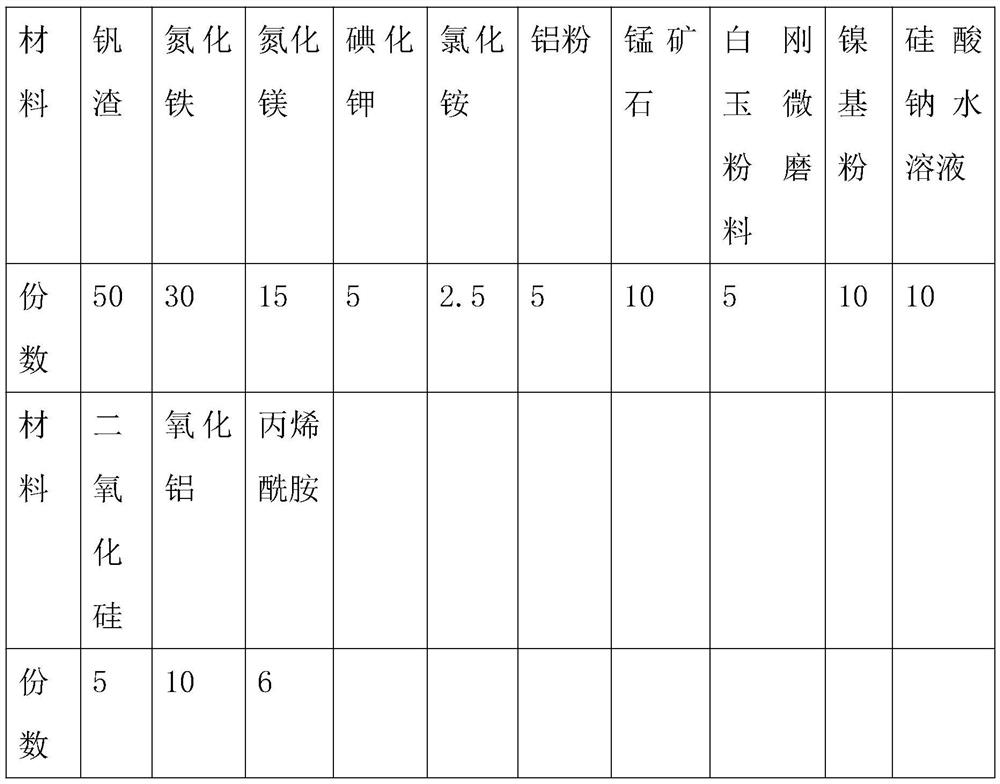

[0036] Embodiment 1, each raw material is calculated by mass parts: 50 parts of vanadium slag, 30 parts of iron nitride, 15 parts of magnesium nitride, 5 parts of potassium iodide, 2.5 parts of ammonium chloride, 5 parts of aluminum powder, 10 parts of manganese ore, white 5 parts of corundum micropowder abrasive, 10 parts of nickel base powder, 10 parts of sodium silicate aqueous solution, 5 parts of silicon dioxide, 10 parts of alumina, 6 parts of acrylamide.

[0037]

[0038] A preparation method for synthesizing a vanadium-nitrogen alloy from vanadium slag, comprising the following steps:

[0039] S1. According to the design standard, weigh the vanadium slag, iron nitride and magnesium nitride, wash the vanadium slag with clean water, and dry it with a dryer after washing. The dried vanadium slag and nitriding Iron and magnesium nitride are mixed, and after mixing, crushing is carried out. After crushing, a 30-mesh sieve is used for screening. The vanadium slag that has...

Embodiment 2

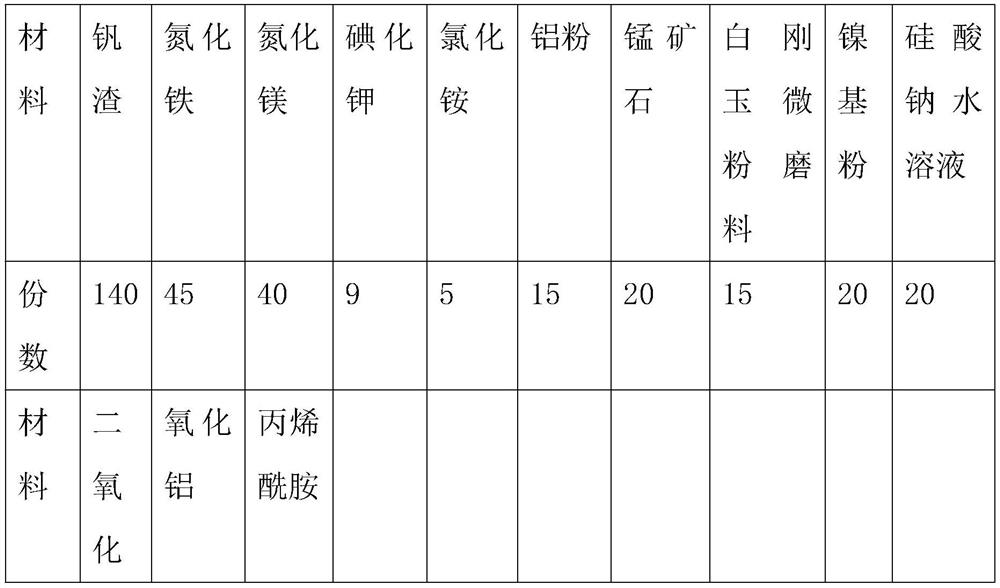

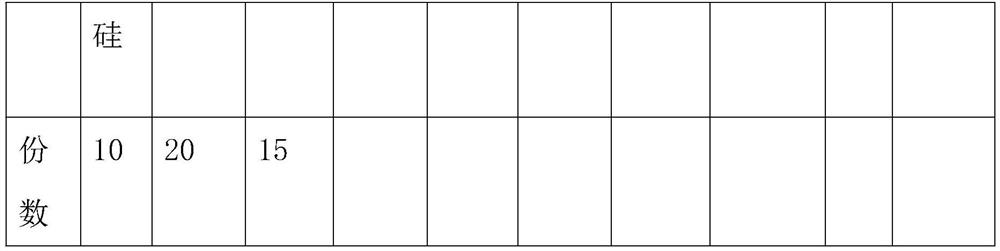

[0044] Embodiment 2, each raw material counts by mass parts: 140 parts of vanadium slag, 45 parts of iron nitride, 40 parts of magnesium nitride, 9 parts of potassium iodide, 5 parts of ammonium chloride, 15 parts of aluminum powder, 20 parts of manganese ore, white 15 parts of corundum micropowder abrasive, 20 parts of nickel base powder, 20 parts of sodium silicate aqueous solution, 10 parts of silicon dioxide, 20 parts of aluminum oxide, and 15 parts of acrylamide.

[0045]

[0046]

[0047] A preparation method for synthesizing a vanadium-nitrogen alloy from vanadium slag, comprising the following steps:

[0048] S1. According to the design standard, weigh the vanadium slag, iron nitride and magnesium nitride, wash the vanadium slag with clean water, and dry it with a dryer after washing. The dried vanadium slag and nitriding Iron and magnesium nitride are mixed, and after mixing, crushing is carried out, and after crushing, a 50-mesh sieve is used for screening, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com