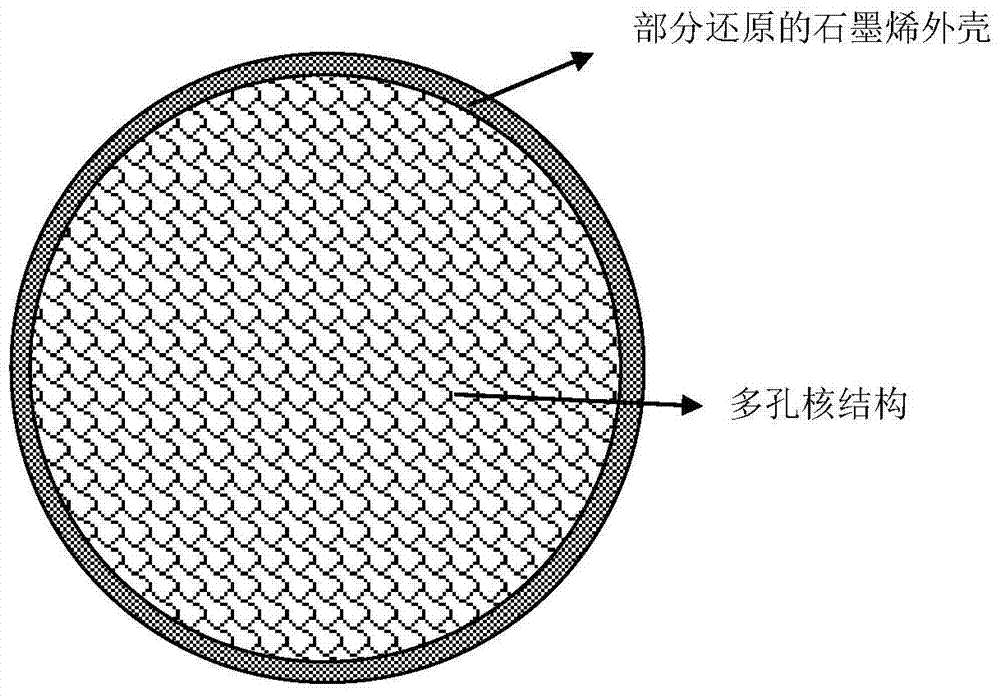

A kind of graphene-coated porous granular material and preparation method thereof

A graphene coating and graphene technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as difficulty in satisfying cheap large-scale preparation, low production efficiency of chemical vapor deposition, and poor penetration of lithium ions. Achieve the effect of avoiding direct contact with silicon, reducing the formation of solid electrolyte membrane, and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Preparation of silicon-containing alloys

[0046] Put silicon and aluminum into a resistance furnace with a mass ratio of 20:80, heat it to 800°C to melt, and keep it warm for 30 minutes. After the alloy composition is uniform, it is poured into an alloy ingot.

[0047] (2) Preparation of alloy powder

[0048] Put the alloy ingot obtained in step (1) into the ladle at the upper end of the spray deposition powder making equipment, heat it to 800°C to melt and keep it warm for 30 minutes, then open the ladle, and use high-purity nitrogen as the cooling medium in the high-speed atomization equipment Al-Si alloy balls with a diameter of 50 microns were prepared.

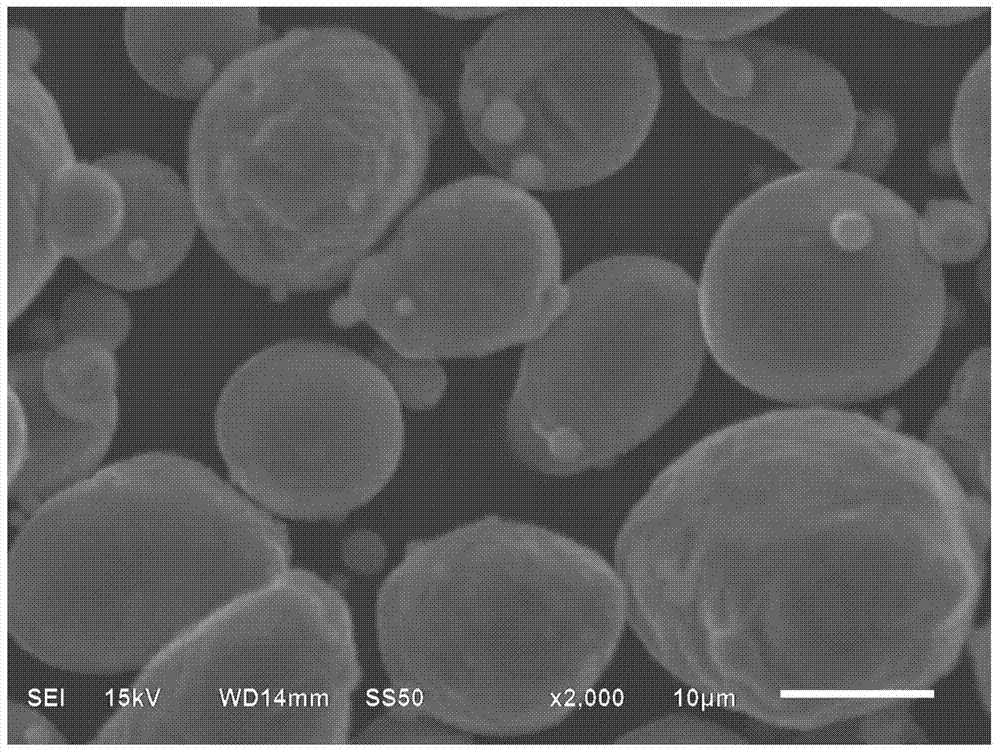

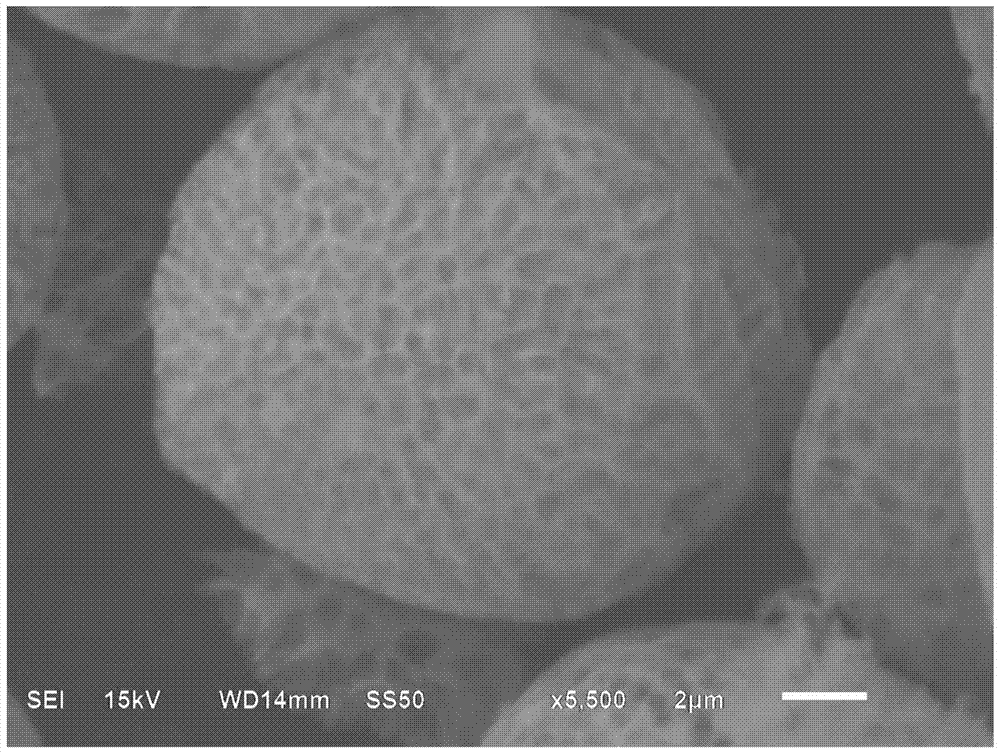

[0049] (3) Preparation of graphene-coated porous silicon composites

[0050] Put the silicon alloy balls obtained in step (2) into the graphene oxide aqueous solution with a concentration of 2 mg / mL, and after magnetic stirring for 24 hours, add sulfuric acid with a concentration of 1 mole per liter, react f...

Embodiment 2

[0052] (1) Preparation of silicon-containing alloys

[0053] Put silicon and zinc metal into a resistance furnace with a mass ratio of 10:90, heat it to 600°C to melt, and keep it warm for 30 minutes. After the alloy composition is uniform, it is poured into an alloy ingot.

[0054] (2) Preparation of alloy powder

[0055] Put the alloy ingot obtained in step (1) into the ladle at the upper end of the spray deposition powder making equipment, heat it to 600°C to melt and keep it warm for 30 minutes, then open the ladle, and use high-purity nitrogen as the cooling medium in the high-speed atomization equipment Al-Si alloy balls with a diameter of 20 microns were prepared.

[0056] (3) Preparation of graphene / silicon composite materials

[0057] Put the silicon alloy spheres obtained in step (2) into an aqueous solution of graphene oxide with a concentration of 5 mg / mL, stir magnetically for 24 hours, add sulfuric acid with a concentration of 2 moles per liter, react for 24 ho...

Embodiment 3

[0059] The rate discharge performance test of graphene-coated porous silicon was carried out according to routine tests. The result is as Figure 7 shown. The performance of the graphene-coated porous silicon material did not change after 20 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com