Preparation method of antibacterial and antiviral environment-friendly interior wall modification coating and product of antibacterial and antiviral environment-friendly interior wall modification coating

An anti-virus and environment-friendly technology, applied in the field of coatings, can solve the problems of easy cracking, insufficient anti-virus performance, and insufficient stability of interior wall decoration coatings, and achieve the effects of low cost, long service life, and easy film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

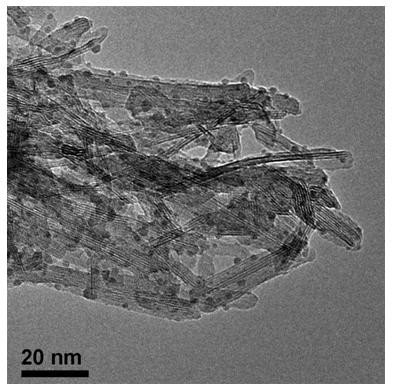

Image

Examples

Embodiment 1

[0042] An antibacterial and antiviral environment-friendly interior wall decoration coating is prepared according to the following steps:

[0043] (1) Preparation of nano inorganic antibacterial and antiviral powder

[0044] Weigh silver nitrate, zinc chloride or copper sulfate, modifier aminotriacetic acid, complexing agent benzo-15-crown-5 and deionized water according to the mass ratio of 1:0.01:0.01:0.01:0.01:1 Firstly, silver salt, zinc salt, copper salt, modifier and complexing agent are added to deionized water, and the power is 1000W ultrasonically assisted by 5000 rpm high-speed shear stirring for 0.5h to modify and complex the metal ions combined to prepare a modified metastable complex silver-zinc-copper composite ion solution, which makes it easier to enter the two-dimensional nanosheet layer and the interlayer;

[0045] Add the two-dimensional nano-layered material zirconium hydrogen phosphate in the metastable complexed silver-zinc-copper composite ion solution ...

Embodiment 2

[0052] An antibacterial and antiviral environment-friendly interior wall finishing paint, similar to the steps of Example 1, is prepared as follows:

[0053] (1) Preparation of nano inorganic antibacterial and antiviral powder

[0054] According to the mass ratio of 1:20:30:50:50:500, weigh inorganic silver salt silver chlorate, zinc salt zinc carbonate, copper salt copper chloride, modifier potassium sodium tartrate, complexing agent diethylenetriaminepenta Acetic acid and solvent ethanol, firstly add silver salt, zinc salt, copper salt, modifier and complexing agent to the solvent, use the power of 3000W ultrasonic assisted 15000 rpm high-speed shear stirring treatment time is 3h for the metal ion Modification and complexation are carried out to prepare a modified metastable complexed silver-zinc-copper composite ion solution, which makes it easier to enter the two-dimensional nanosheets and interlayers;

[0055] Add the two-dimensional nano-layered material graphite phase ...

Embodiment 3

[0062] An antibacterial and antiviral environment-friendly interior wall finishing paint, similar to the steps of Example 1, is prepared as follows:

[0063] (1) Preparation of nano inorganic antibacterial and antiviral powder

[0064] According to the mass ratio of 1:5:2:100:100:300, weigh inorganic silver salt silver bicarbonate, zinc salt zinc acetate, copper salt copper nitrate, modifier dithizone, complexing agent PN methylsulfonic acid Sodium and solvent isopropanol, first add silver salt, zinc salt, copper salt, modifier and complexing agent to the solvent, adopt the method of 8000W ultrasonic assisting 30000 rpm high-speed shearing and stirring for 10h Metal ions are modified and complexed to prepare a modified metastable complexed silver-zinc-copper composite ion solution, which makes it easier to enter the two-dimensional nanosheets and interlayers;

[0065] Add the two-dimensional nano-layered material nickel-cobalt lithium manganate to the metastable complex silve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com