Fiber-reinforced polymer strip with improved durability and lattice geogrid using same

A fiber-reinforced, thermoplastic polymer technology, used in geotextiles, soil protection, underwater structures, etc., can solve the problems of poor shape stability of friction characteristics vertical load, contact point strength of lattice geogrids, The strip does not form bonds and other issues, resulting in excellent shape stability and construction resistance, increased resistance, low tensile strain and creep deformation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

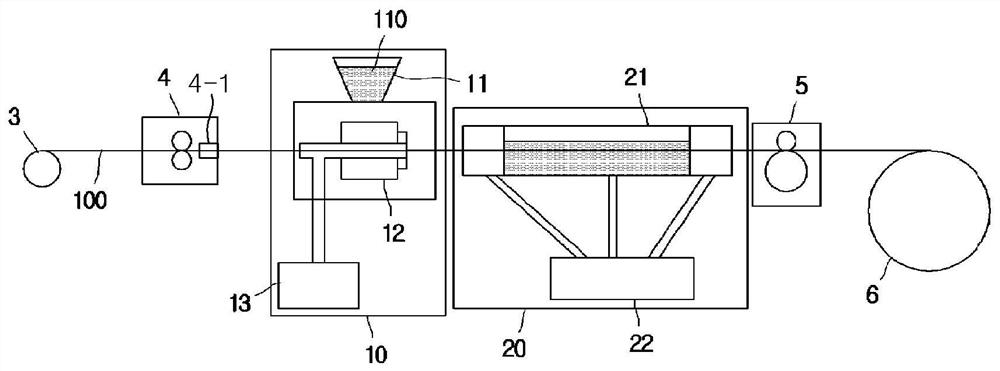

Image

Examples

Embodiment Construction

[0033] The following preferred embodiments of the present invention will be described. First, in the description of the present invention, a detailed description will be omitted of the relevant known functions or configuration, to avoid obscuring the gist of the invention.

[0034] Degree used in the present specification indicates the term "about", "substantially" and the like means that when the inherent manufacturing and material meanings stated tolerance, or the value close to the value sense, and in order to help prevent correct or absolute values disclosure understanding of the invention mentioned by unscrupulous persons against improper use.

[0035] The present invention relates to an improved durability of the fiber-reinforced polymer strips, the fiber reinforced polymer strip composed of the following: a plurality of reinforcing fiber aggregate material; thermoplastic polymer as a coating material resin; and in the said reinforcing material having a surface bonding mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com