Cooling device for laminated glass autoclave

A cooling device and laminated glass technology, applied in lamination devices, cooling fluid circulation devices, household refrigeration devices, etc., can solve the problems of slow cooling process, waste of water resources, etc., achieve fast cooling rate, reduce energy flow water, heat Exchange full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

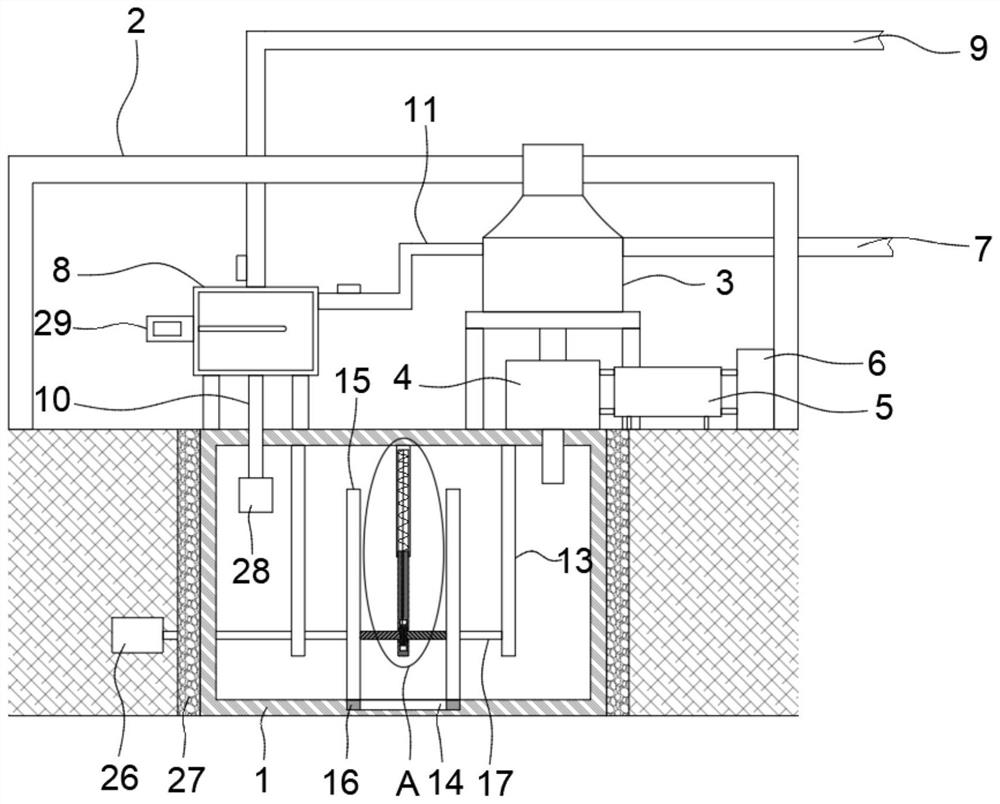

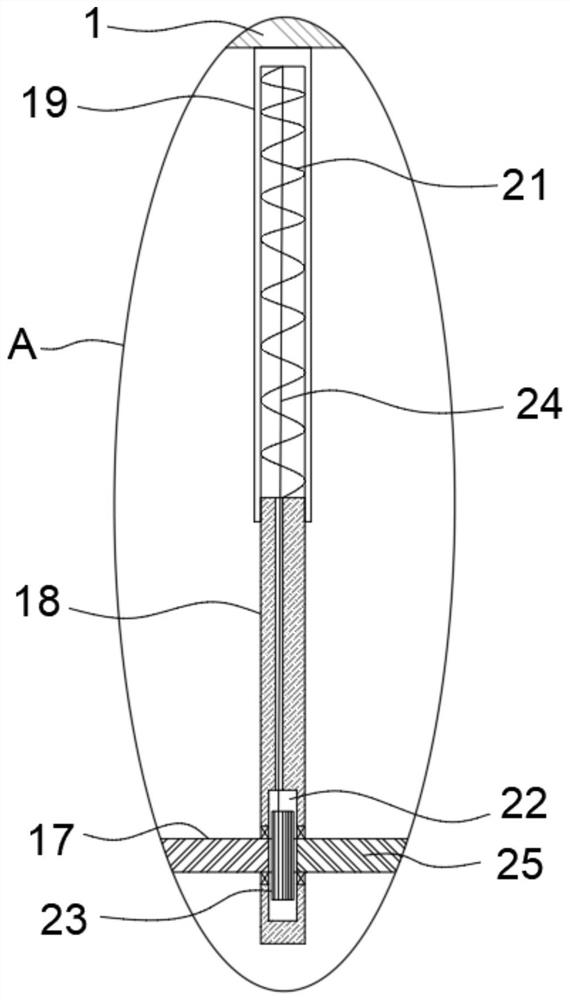

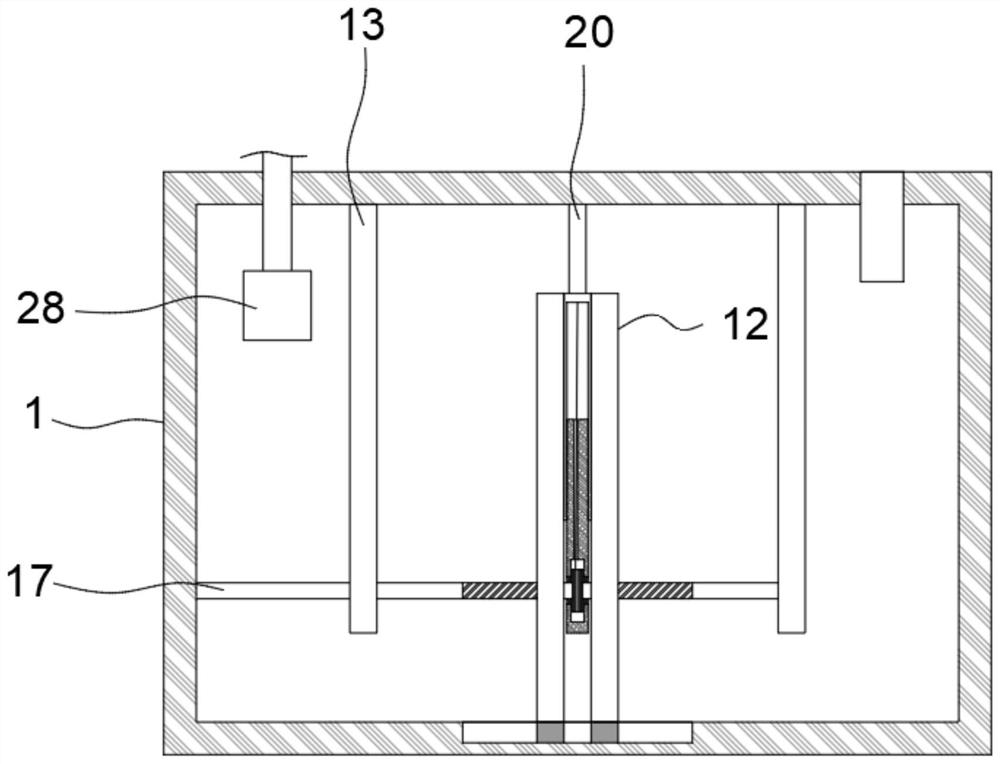

[0022] Refer Figure 1-3 A laminated glass autoclave cooling apparatus, comprising a box opened in the ground slot, groove box 1 is provided with a water storage tank, water storage tank 1 in advance filled with water at room temperature, an outside water storage tank 27 is wrapped with insulation , a water storage tank disposed below the ground, the soil in the insulation layer 27 functions as a good insulation effect, when the water tank 1 is hardly affected by the outside temperature, on the ground and fill tank 1 is provided with a sunshade in position 2, 2 awnings can effectively avoid direct sunlight for outdoor water tank 1, reducing the temperature of the upgrade. 2 awning provided with a cooling wind tower 3, the cooling air inlet end of column 3 communicates with a hot water inlet conduit 7, water inlet pipe 7 for conveying water into the autoclave, the cooling air discharged from column 3 3 is a tower cooling air prior art, the cooling of the hot water preliminary work, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com