Method and device for preparing high purity metal or alloy through efficient distillation method

A distillation method and a technology for purifying metals, which are applied in the field of high-efficiency distillation to prepare high-purity metals or alloys, and can solve the problems of low efficiency in purifying metals or alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

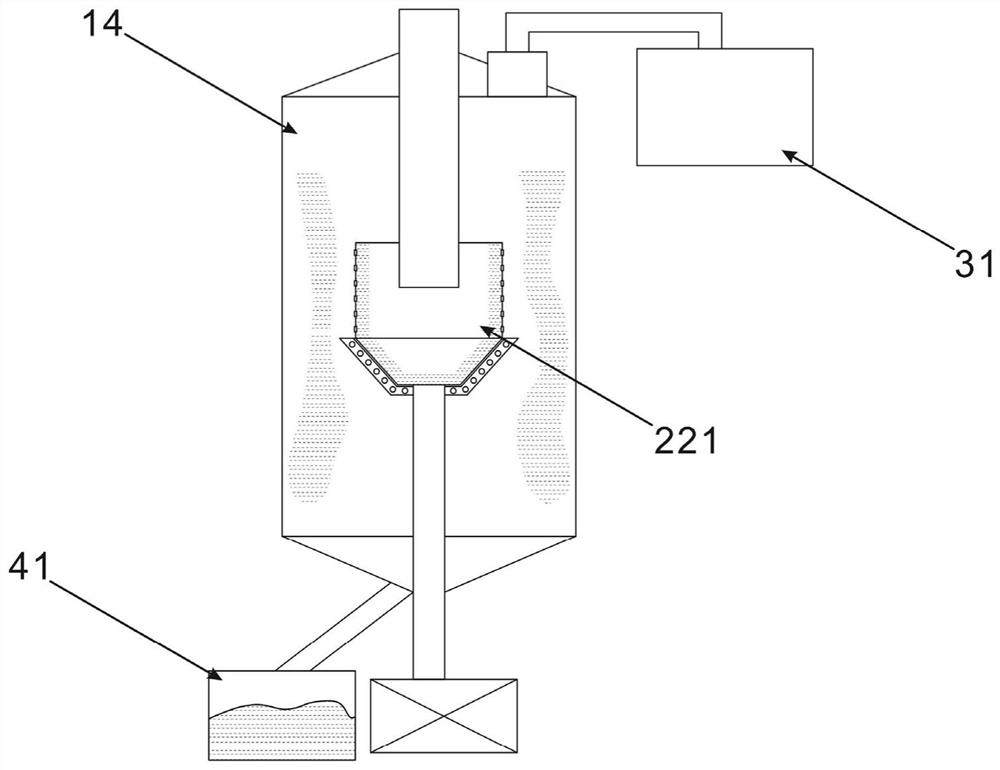

[0047] The invention provides a method for preparing high-purity high-boiling point metals or alloys by high-efficiency distillation, which is suitable for the preparation of high-boiling point high-purity metals or alloys. Taking the preparation of high-purity aluminum metal as an example, refer to figure 1 and Figure 4 , the method for preparing high-purity aluminum metal by high-efficiency distillation at least includes the following steps:

[0048] Step (I) Melting: heating primary purity aluminum ingot (melting point: 600°C) to 900°C to melt it to form molten metal aluminum.

[0049] If necessary, the alloying agent can be added to alloy and float some impurities or precipitate and separate them.

[0050] Step (II) centrifugation: import the molten metal aluminum into the centrifuge chamber 221, and the centrifuge chamber 221 rotates at a speed of 120r / min. The communication hole 224 with a diameter of 3 mm on the wall enters the distillation chamber 14 to realize drop...

Embodiment 2

[0056] The difference between embodiment 2 and embodiment 1 is:

[0057] In step (IV), the collection chamber 41 is set as a casting pool, and the high-purity aluminum metal droplets are continuously melted and cast in the casting pool to produce rod-shaped, strip-shaped or block-shaped profiles of different sizes.

Embodiment 3

[0059] The difference between embodiment 3 and embodiment 1 is:

[0060] In step (IV), the collection chamber 41 is set as a cooling chamber, and the high-purity aluminum metal droplets are cooled in the cooling chamber, and under the action of its surface tension, aluminum powder is formed, which is used for powder coating, 3D printing and powder coating. Metallurgy, etc.

[0061] The present invention also provides embodiment 4 and embodiment 5, and its difference with above-mentioned embodiment 1-3 is:

[0062]

[0063]

[0064] All the other steps are the same.

[0065] Adopt the preparation method of embodiment 1-embodiment 5 and the molten metal purity before and after its treatment is described in the table below:

[0066] Example Metal Before purification (%) After purification (%) 1 aluminum 99.95 99.991 2 aluminum 99.95 99.987 3 aluminum 99.95 99.982 4 copper 99.97 99.996 5 manganese 99.93 99.980

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com