Anti-torsion bearing disc in badminton shoes and production method thereof

A production method and anti-torsion technology, applied in chemical instruments and methods, shoe soles, footwear, etc., can solve the problems of carbon plate fracture, poor torsional resistance of sneakers, low fracture toughness between layers, etc. The effect of solving the easy torsion deformation and improving the interlayer toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment one (mainly increasing strength and toughness):

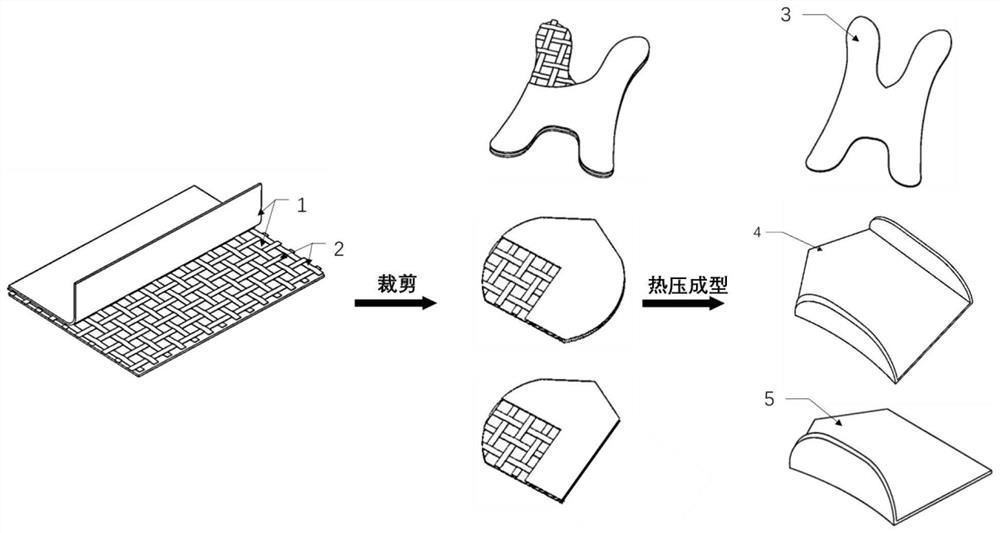

[0052] Such as figure 2 As shown, the anti-twist support tray includes carbon fiber prepreg 1, surface-treated amorphous alloy belt 2, a production method of anti-twist support tray in badminton shoes, including steps:

[0053] Step S1: Paste a mesh made of surface-treated amorphous alloy tape on a carbon fiber prepreg cloth. The amorphous alloy mesh extends out of the carbon cloth by 10mm-50mm, and then paste another carbon fiber prepreg cloth, and then continue Lay carbon fiber prepreg on both surfaces and let it stand for 12 hours;

[0054] Step S2: cutting the composite material obtained in step S1 according to the shape of the anti-twist support tray;

[0055] Step S3: Put the cut composite material into the forming mold, solidify and form under the heating condition of 110-220° C., and take out the formed anti-twist support tray in the mold after cooling.

[0056] In more detail, the preparation and ...

Embodiment 2

[0065] Embodiment 2 (mainly increasing flexibility):

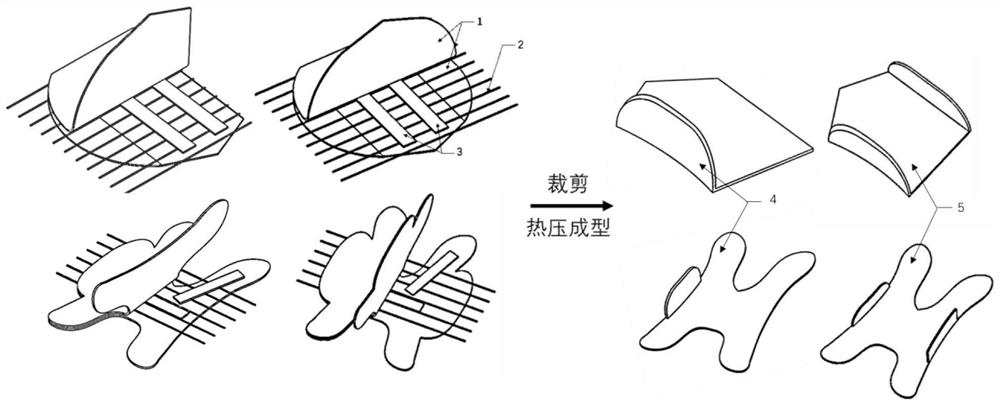

[0066] Such as image 3 As shown, the anti-rotation support tray includes a carbon fiber prepreg 1 after cutting, an amorphous alloy wire 2 after surface treatment, and an amorphous alloy sheet 3 after surface treatment.

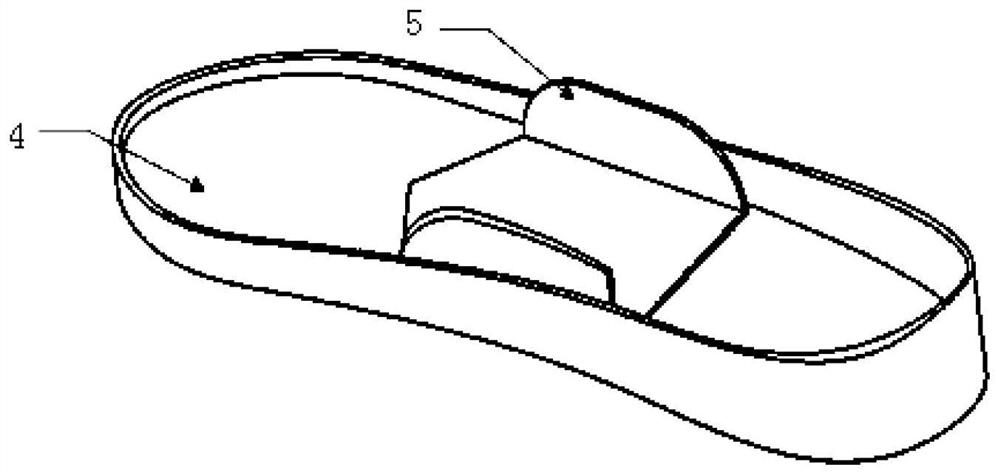

[0067] The L-shaped anti-rotation support tray 4 is raised on one side to form a single side wall.

[0068] Both sides of the anti-rotation support tray 5 of the U-shaped structure are tilted to form double side walls.

[0069] A method for producing an anti-rotation support tray in badminton shoes, comprising the steps of:

[0070] Step S1: Paste the surface-treated amorphous alloy wire on a carbon fiber prepreg cloth after cutting, and the amorphous alloy wire extends out of the carbon cloth by 10mm-100mm;

[0071] Step S2: Paste the surface-treated amorphous alloy sheet on the designated position on the amorphous alloy wire and carbon cloth, and then paste another piece of carbon cloth impregnated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com