Porous powder loaded with super-hydrophobic particles as well as preparation method and application of porous powder

A porous powder and super-hydrophobic technology, applied in chemical instruments and methods, sustainable manufacturing/processing, coating, etc., can solve the problems of poor formula applicability, poor environmental stability, cumbersome process, etc., and achieve improved tensile strength, Improved mechanical performance and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

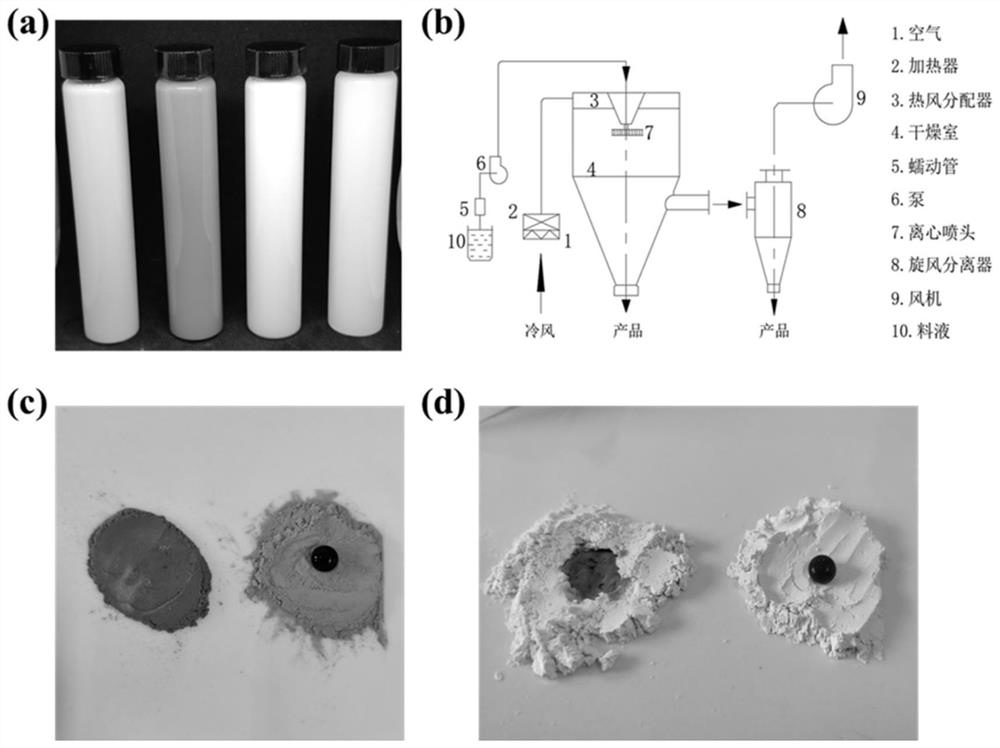

[0040] In this example, the inorganic nanoparticles are alumina, the solvent is water, the hydrophobic modifier is water-based propyloctylsiloxane oligomer Evonik Protectosil WS 670, and the porous microparticles are made of alumina and silica. Porous ceramic particles sintered at high temperature, the preparation steps are as follows, in parts by mass:

[0041] (1) Add 10 parts of nano-alumina sol, 5 parts of ammonia water, and 1.6 parts of aqueous propyloctylsiloxane oligomer Protectosil WS670 to 100 parts of deionized water and continuously stir for 24 hours to obtain a modified nanoparticle suspension;

[0042] (2) Spray-dry the nanoparticle suspension prepared in step (1) for 1-2 hours at an inlet temperature of 160-220° C., a spray air pressure of 0.3 MPa, and a water evaporation rate of 1-200 L / h to remove deionized water, and obtain Nanoparticle powder;

[0043] (3) Add 9 parts of porous ceramic particles made by high-temperature sintering, 0.2 parts of Evonik Dynasyl...

Embodiment 2

[0048] In this example, the inorganic nanoparticles are silica, the volatile organic solution is propylene glycol methyl ether, the water-based hydrophobic treatment agent is water-based perfluoroalkylsiloxane, and the porous micro-particles are made of silica, alumina, and zirconia. Porous ceramic particles made by high-temperature sintering, the preparation steps are as follows, in parts by mass:

[0049] (1) Disperse 8 parts of nano-silica sol, 4 parts of ammonia water, and 0.5 parts of aqueous perfluoroalkylsiloxane in 100 parts of deionized water, and continuously stir for 24 hours to prepare a modified nanoparticle suspension;

[0050] (2) Spray-dry the superhydrophobic nano-coating prepared in step (1) for 1-2 hours under the conditions of inlet temperature 160-220°C, spray air pressure 0.3MPa, and water evaporation 1-200L / h to remove deionized water to obtain a superhydrophobic coating. Hydrophobic modified nanoparticle powder;

[0051] (3) Add 4 parts of porous ceram...

Embodiment 3

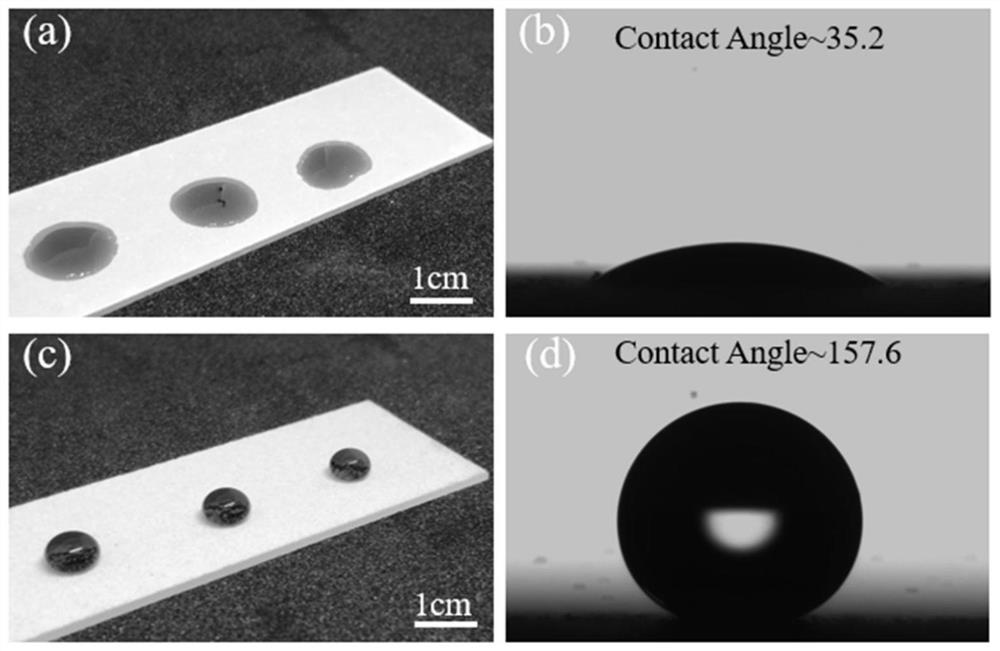

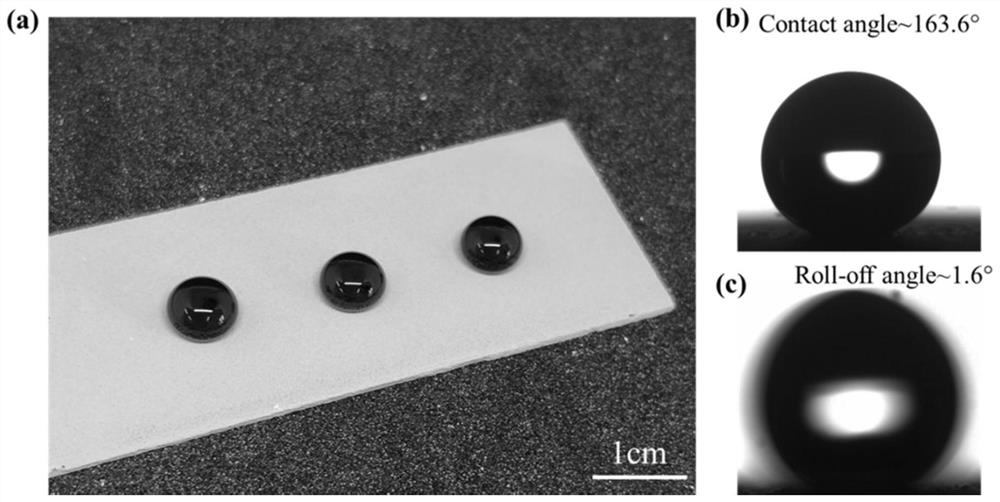

[0056] Figure 5 The mechanical abrasion resistance of the superhydrophobic coating prepared for the porous powder loaded with superhydrophobic particles in Example 2 and the SEM image of the surface after being subjected to severe mechanical abrasion. Thanks to the good dispersion of the porous powder loaded with super-hydrophobic particles and the strong binding force with the binder, as well as the "armor" protection of the porous ceramic particles with high strength and high temperature sintering optimized through experiments and the ability to withstand harsh The release of superhydrophobic nanoparticles under mechanical damage, the superhydrophobic coating can still maintain excellent superhydrophobic properties after 2000 cycles of Taber abrasion (1kg load).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water droplet contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com