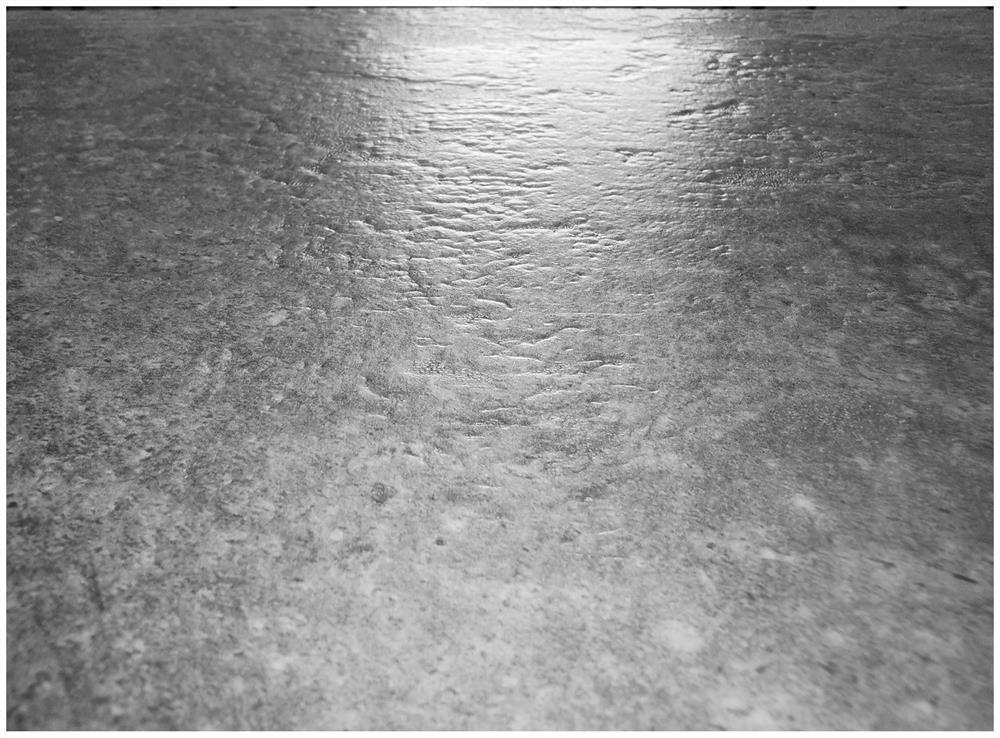

Volcanic glaze and rock plate

A volcanic rock and glaze technology, applied in the field of architectural ceramics, can solve the problems of high prices, difficult mining, scarcity of natural rocks, etc., and achieve the effect of delicate and smooth touch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

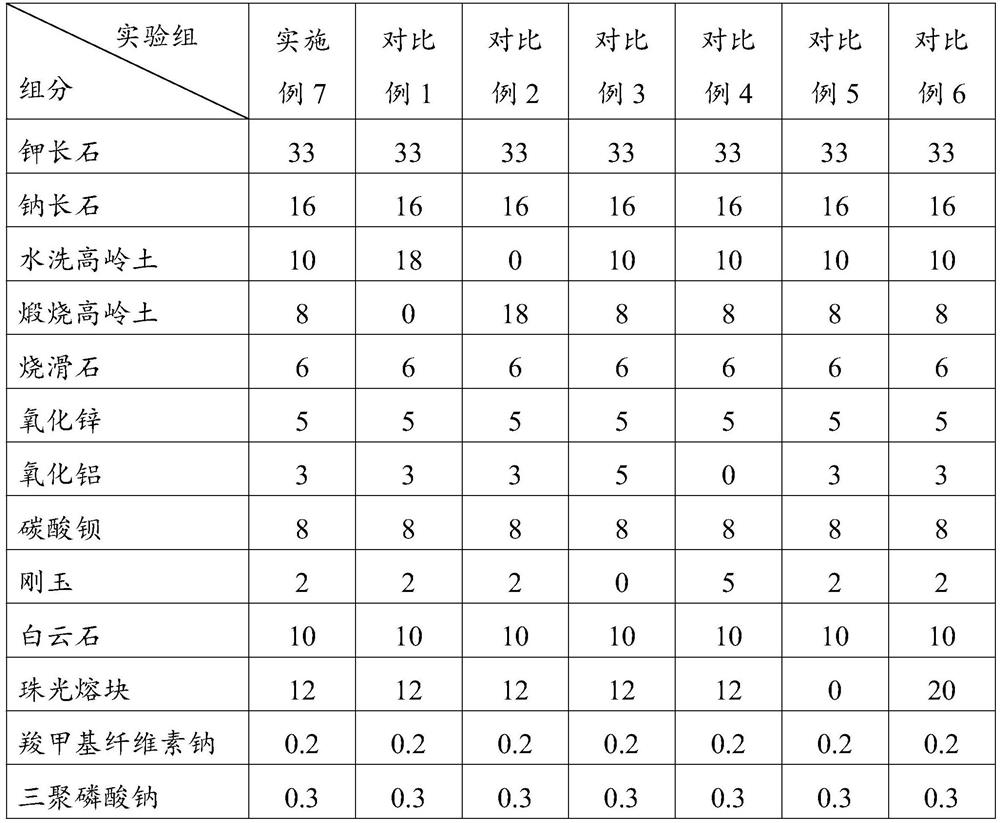

[0030] A volcanic rock glaze, comprising the following components in parts by weight:

[0031] 20 parts by weight of potassium feldspar; 20 parts by weight of albite; 12 parts by weight of washed kaolin; 5 parts by weight of calcined kaolin; 8 parts by weight of calcined talc; 3 parts by weight of zinc oxide; 1 part by weight of aluminum oxide; 8 parts by weight of barium carbonate; 5 parts by weight of corundum; 9 parts by weight of dolomite; 10 parts by weight of pearlescent frit; appropriate amount of sodium carboxymethyl cellulose; appropriate amount of sodium tripolyphosphate.

Embodiment 2

[0033] 25 parts by weight of potassium feldspar; 10 parts by weight of albite; 8 parts by weight of washed kaolin; 8 parts by weight of calcined kaolin; 6 parts by weight of calcined talc; 5 parts by weight of zinc oxide; 3 parts by weight of aluminum oxide; 10 parts by weight of barium carbonate; 2 parts by weight of corundum; 8 parts by weight of dolomite; 12 parts by weight of pearlescent frit; appropriate amount of sodium carboxymethyl cellulose; appropriate amount of sodium tripolyphosphate.

Embodiment 3

[0035] 30 parts by weight of potassium feldspar; 15 parts by weight of albite; 10 parts by weight of washed kaolin; 6 parts by weight of calcined kaolin; 5 parts by weight of calcined talc; 4 parts by weight of zinc oxide; 2 parts by weight of aluminum oxide; 9 parts by weight of barium carbonate; 3 parts by weight of corundum; 10 parts by weight of dolomite; 10 parts by weight of pearlescent frit; appropriate amount of sodium carboxymethyl cellulose; appropriate amount of sodium tripolyphosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com