Inorganic rock-wool thermal insulation decorating plate with leveling natural stone paint surface

A natural stone and decorative board technology, applied in covering/lining, construction, coating, etc., can solve problems such as heat insulation, waterproof, poor self-cleaning ability, ineffective protection of the insulation layer, and affecting the aesthetic effect of the building. Achieve the effect of improving the overall waterproof performance, excellent self-cleaning performance, and improving the overall sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

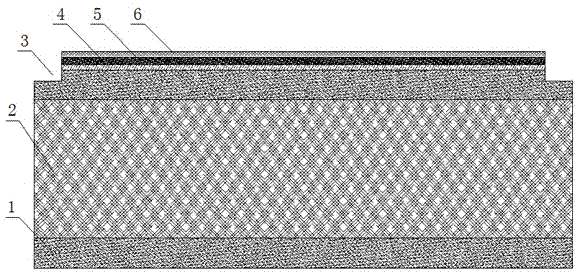

[0017] Such as figure 1 Shown: the leveling natural stone lacquer surface inorganic rock wool thermal insulation decorative board of the present invention includes an insulating layer 2 made of inorganic rock wool, and the upper and lower sides of the insulating layer 3 are provided with silicon-calcium boards as the reinforcement layer 1, The outer surface of one side of the calcium silicate board is coated with a leveling natural stone paint finish layer, which is composed of a primer layer 4, a natural stone paint layer 5 and a top coat layer 6, wherein the natural stone paint layer 5 It is compounded with 40-80 mesh stone powder, 80-120 mesh stone powder, silicone acrylic emulsion, thickener, leveling agent, dustproof agent, anti-ultraviolet agent, PH value regulator, and deionized water. It is formed by spraying and vibrating leveling of natural stone paint with excellent leveling properties, and the periphery of the decorative layer and the calcium-silicon board connecte...

Embodiment 2

[0024] The difference between this embodiment and Embodiment 1 is that the leveling natural stone paint used is made of the following raw materials in parts by weight: 17 parts of 60-mesh stone powder, 51 parts of 100-mesh stone powder, silicon acrylic 17 parts of emulsion, 0.4 part of thickener, 0.5 part of leveling agent, 0.3 part of dustproof agent, 0.2 part of anti-ultraviolet agent, 0.15 part of pH regulator, 10 parts of deionized water. The mounting edge 3 of the trapezoidal structure is integrally pressed and formed when the substrate is manufactured.

Embodiment 3

[0026] The difference between this embodiment and Embodiment 1 is that the leveling natural stone paint used is made of the following raw materials by weight: 20 parts of 80-mesh stone powder, 55 parts of 120-mesh stone powder, silicon acrylic 20 parts of emulsion, 0.5 part of thickener, 0.6 part of leveling agent, 0.4 part of dustproof agent, 0.3 part of anti-ultraviolet agent, 0.2 part of pH regulator, 12 parts of deionized water. And after the leveling natural stone paint is sprayed, the natural stone paint layer 5 of the thermal insulation decorative board is vibrated and leveled by mechanical vibration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com