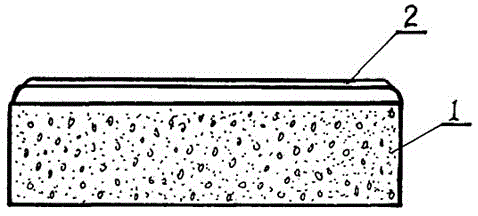

Reflection heat insulation and preservation veneer integrated external wall panel sectional material

A thermal insulation and integrated technology, applied in the direction of covering/lining, construction, chemical instruments and methods, etc., can solve the problems of rough operation, unsafe construction, labor and labor, etc., and reduce the internal space temperature and production cost Reduce and save the effect of stone resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The weight ratio of each component raw material of the facing layer is: 60 parts of waste rock debris, 5 parts of hollow glass microspheres, 1 part of vitrified microspheres, 1 part of rare earth metal oxide, 1 part of rutile, water-based 15 parts of emulsion, 3 parts of inorganic binder, 0.3 part of wood fiber, 0.3 part of polypropylene short fiber, 0.02 part of film-forming aid, 2 parts of water.

Embodiment 2

[0029] The weight ratio of each component raw material of the facing layer is: 65 parts of waste rock debris, 8 parts of hollow glass microspheres, 2.5 parts of vitrified microspheres, 2.5 parts of rare earth metal oxides, 2.5 parts of rutile, water-based 16.5 parts of emulsion, 3.5 parts of inorganic binder, 0.35 parts of wood fiber, 0.35 part of polypropylene short fiber, 0.025 part of film-forming aid, and 3 parts of water.

Embodiment 3

[0031] The weight ratio of each component raw material of the facing layer is: 70 parts of waste rock debris, 11 parts of hollow glass microspheres, 3.5 parts of vitrified microspheres, 3.5 parts of rare earth metal oxides, and 3.5 parts of rutile , 18.5 parts of water-based emulsion, 4.5 parts of inorganic binder, 0.45 parts of wood fiber, 0.45 part of polypropylene short fiber, 0.028 part of film-forming aid, and 4 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com