Porous titanium dioxide nano material, metal nanoparticle modified porous titanium dioxide photocatalytic material and preparation method and application of metal nanoparticle modified porous titanium dioxide photocatalytic material

A technology of porous titanium dioxide and metal nanoparticles, which is applied in the field of photocatalytic materials and their preparation, porous titanium dioxide nanomaterials, can solve the problems of high cost and high energy consumption, and achieve the reduction of hydrolysis speed, prolongation of reaction time and homogenization degree high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a method for preparing porous titanium dioxide nanomaterials, which includes the following steps: adding urea and titanium source into the aqueous solution, heating to 80-120°C, and keeping it warm for 1-3 days, and the obtained product is treated to obtain a white Powdered porous titania nanomaterials. The reaction temperature for heating is preferably 85 to 115°C, more preferably 90 to 110°C.

[0045] Further, the processing step includes: washing the product with distilled water and ethanol respectively, and drying at 30-80°C for 1-10 hours. The treatment conditions are preferably 40-70°C for 3-8 hours; more preferably 45-65°C for 5-7 hours.

[0046] The present invention also provides a metal nanoparticle-modified porous titanium dioxide modified photocatalytic material, using the above-mentioned porous titanium dioxide nanomaterial, the photocatalytic material is prepared by adding the porous titanium dioxide nanomaterial to a s...

Embodiment 1

[0062] Add urea and isopropyl titanate at a mass ratio of 1:1 to water respectively, and then heat to 100° C. for 2 days to react. Subsequently, the product was washed with distilled water and ethanol respectively, and dried to obtain porous titanium dioxide as a white powder material. Take 0.2g of porous titanium dioxide and evenly spread it on the surface of the quartz reactor, eliminate the air by decompression treatment, then fill the quartz reactor with 5ml (about 200μmol) of methane gas, and use a 100W wavelength at 200 ~ 400nm at room temperature The ultraviolet light source irradiated the reactor for 1 h, and the composition of the product was analyzed by gas chromatography equipped with an FID detector. The composition of the product is: ethylene 95.4%, ethane 3.6%.

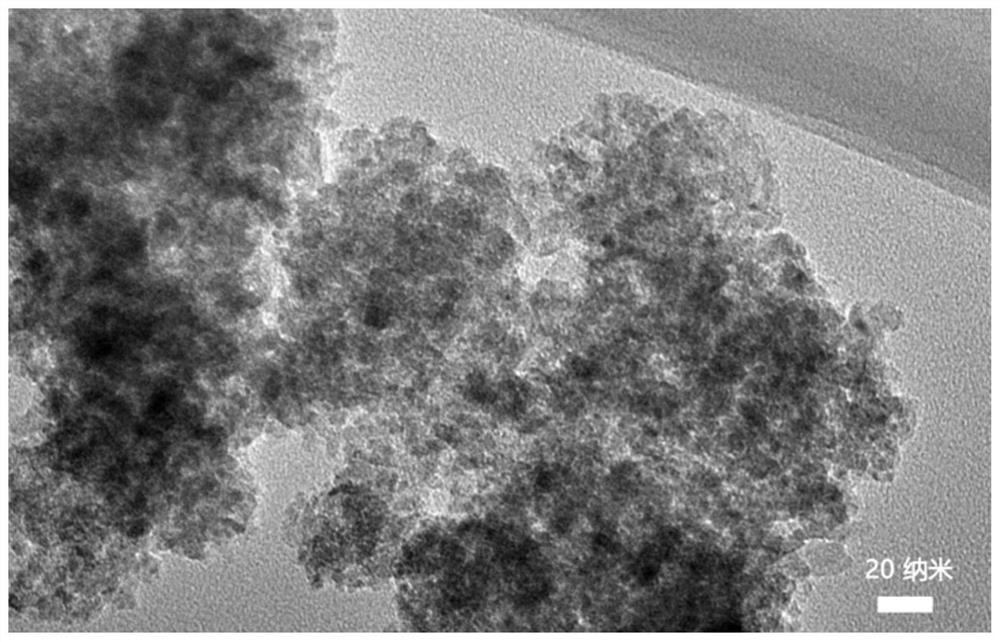

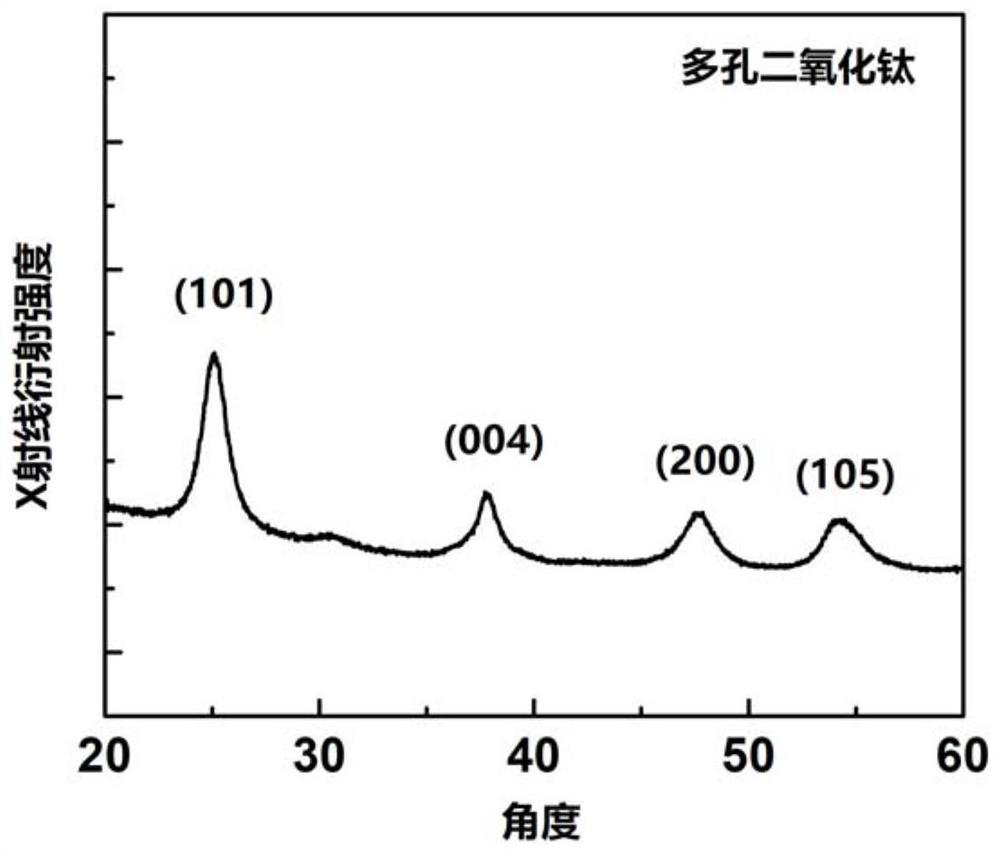

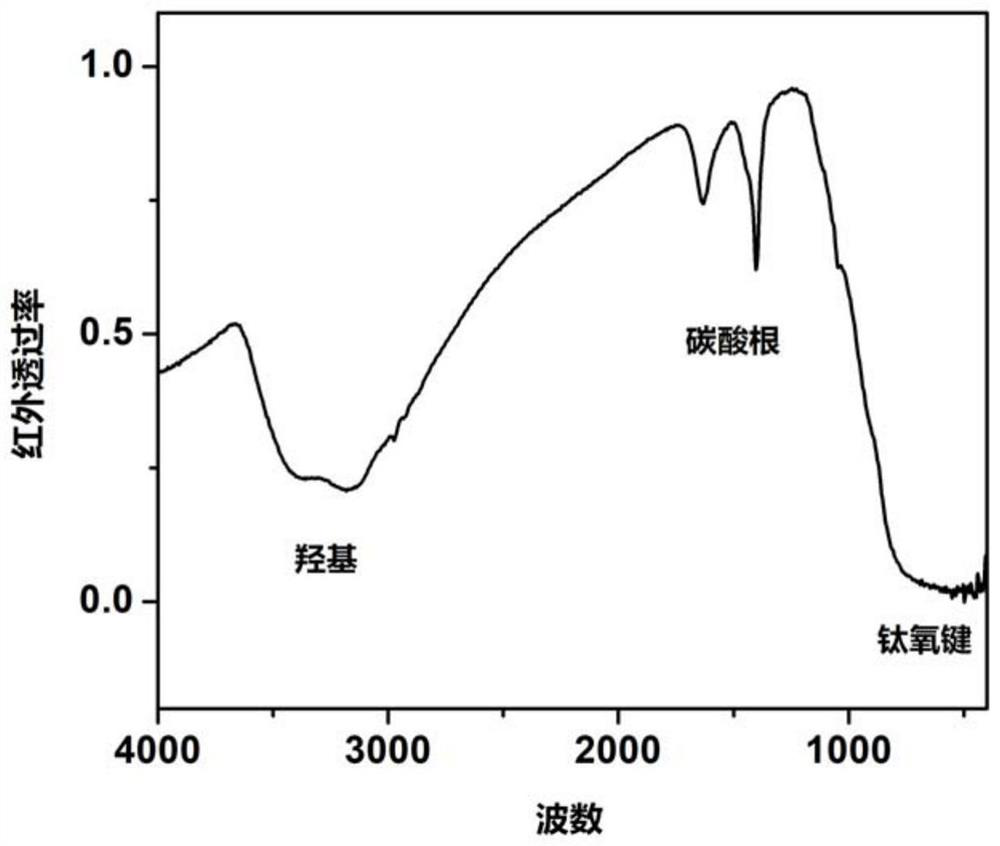

[0063] Example 1 obtains porous titanium dioxide and carries out electron microscope characterization, and its result is as follows figure 1 As shown, the results show that the particle size of the por...

Embodiment 2

[0065] Add urea and tetraisopropyl titanate at a mass ratio of 1:1 to water respectively, and then heat to 100° C. for 2 days to react. Subsequently, the product was washed with distilled water and ethanol, and dried to obtain white powdery porous titanium dioxide. Subsequently, 1 gram of porous titanium dioxide was dispersed in water, 6.65 mg of chloroplatinic acid was added, and then the chloroplatinic acid was decomposed by ultraviolet light to generate platinum nanoparticles, which were modified in the porous titanium dioxide.

[0066] Take 0.2g of porous titanium dioxide and evenly spread it on the surface of the quartz reactor, eliminate the air by decompression treatment, then fill the quartz reactor with 5ml (about 200 μmol) of methane gas, and use a 100W wavelength at 200 ~ 400nm at room temperature The reactor was irradiated with ultraviolet light source for 1 h, and the product composition was analyzed by gas chromatography equipped with FID detector. The product c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com