Alkyl glycoside biological bacteriostatic agent and preparation process thereof

A technology of biological bacteriostatic agents and alkyl glycosides, which is applied in the preparation of sugar derivatives, the preparation of aminohydroxy compounds, and sugar derivatives, etc. Good and other problems, to achieve the effect of obvious bacteriostatic effect, good stability and good biodegradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation aids:

[0045] Step S21: Dissolving the rosin with dichloromethane, then adding thionyl chloride, and performing a reflux reaction at 40° C. for 4 hours. After the reaction, post-processing is performed. The post-processing process is as follows: the obtained reaction solution is concentrated under reduced pressure to remove dichloromethane. and excess thionyl chloride to obtain intermediate 1;

[0046] Step S22: Mix intermediate 1 and dichloromethane, then add N,N-dimethylethanolamine and triethylamine, heat under reflux for 3 hours at a temperature of 50°C, and perform post-processing after the reaction is completed. The process of post-processing As follows: the obtained reaction solution is cooled and filtered under reduced pressure, the obtained filtrate is washed twice with 1% hydrochloric acid aqueous solution and 1% sodium hydroxide aqueous solution respectively, and the organic phase is dried with anhydrous sodium sulfate, Filter, then concentrate ...

Embodiment 2

[0051] Preparation of bacteriostatic components:

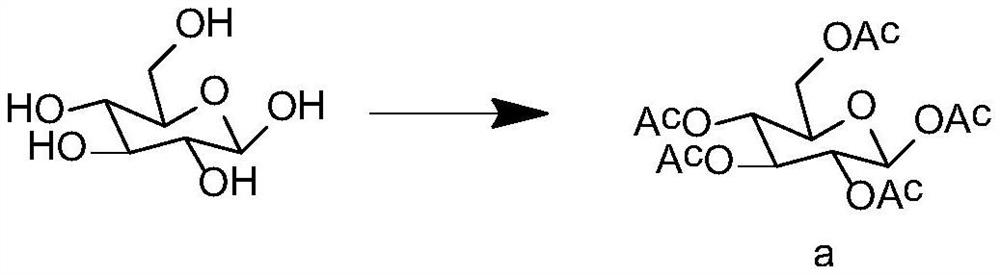

[0052] Step S11, mixing sodium acetate and glucose, adding acetic anhydride after mixing, heating to reflux, stirring and reacting for 2h, and performing post-processing after the reaction is completed. Stir at ℃ for 3.5 h, let stand, remove the upper layer liquid, and then wash with deionized water. After washing, dry at 40 ℃ to constant weight to obtain intermediate a;

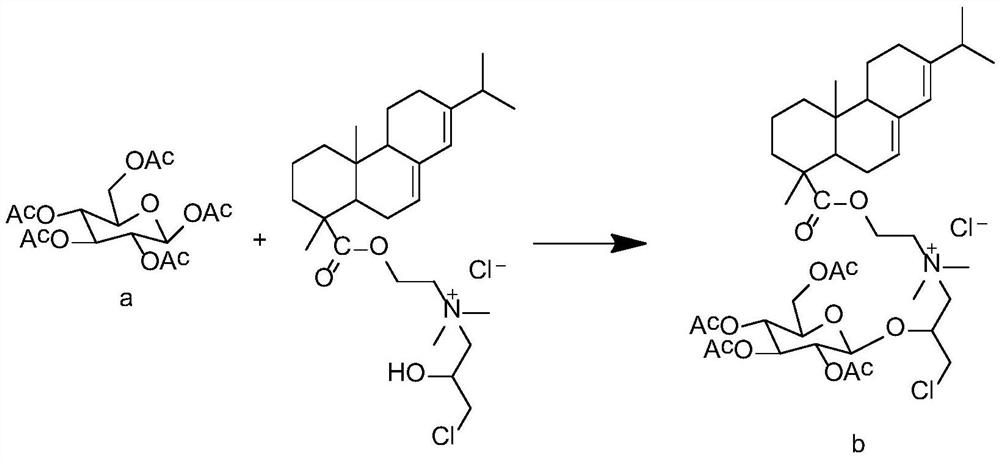

[0053] Step S12, adding intermediate a and auxiliary agents into dichloromethane, then adding boron trifluoride ether, and stirring at room temperature for 24 h to obtain intermediate b;

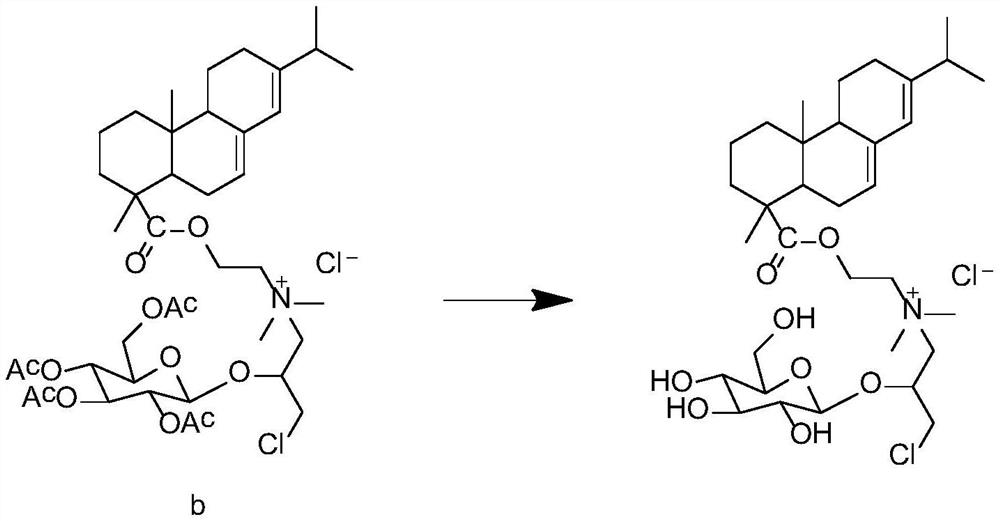

[0054] Step S13, adding intermediate b to the triethylamine solution, stirring at room temperature for 24 hours, to obtain an antibacterial component.

[0055] Among them, the dosage ratio of sodium acetate, glucose and acetic anhydride is 10g: 12.5g: 62.5mL; the dosage ratio of intermediate a, auxiliary agent, dichloromethane and boron trifluoride ether is 3.9g: 2.1g: 50...

Embodiment 3

[0057] Preparation of Alkyl Glycoside Biostatics:

[0058] Ethyl cellulose 1%; Eudragit E100 1%; Hydroxypropyl cellulose 2%; Anhydrous ethanol 40%; Triethyl citrate 1%; Chitosan hydrochloride 1%; Fatty alcohol polyoxyethylene Ether 1%; antibacterial component 1%; solvent supplemented to 100%;

[0059] The preparation process includes the following steps:

[0060] The first step, adding ethyl cellulose into deionized water at 60°C to swell, for later use; mixing Eudragit E100, hydroxypropyl cellulose and absolute ethanol, and then adding the swollen ethyl cellulose to obtain the first mixture ;

[0061] The second step, mixing triethyl citrate, chitosan hydrochloride and fatty alcohol polyoxyethylene ether to obtain a second mixture, after mixing the first mixture and the second mixture, add the bacteriostatic component and solvent, and mix evenly , to obtain an alkyl glycoside biological bacteriostatic agent, and the solvent is purified water. The antibacterial component w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com