Method for preparing superhard hydrophobic self-cleaning thin film

A self-cleaning, thin-film technology, applied in ion implantation plating, coating, metal material coating process, etc., can solve the problems of freezing and frosting, easy corrosion, and non-wear-resistant material surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

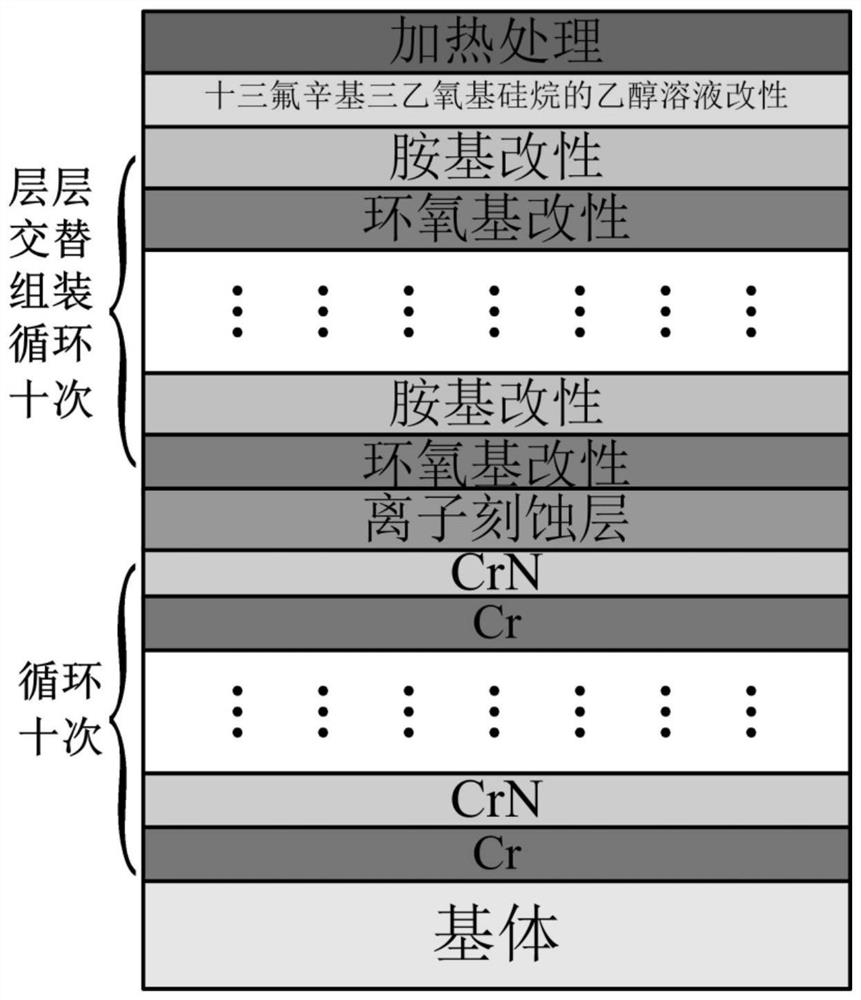

[0028] Embodiment 1: This embodiment is a method for preparing a superhard hydrophobic self-cleaning film, which includes the following steps:

[0029] 1. Substrate pretreatment: put the Q235 steel substrate in KOH and NaHCO 3 Remove oil from the mixture, rinse and neutralize with dilute HCl, and then grind and polish step by step with metallographic sandpaper, then ultrasonically clean in acetone and absolute ethanol, and dry with cold air;

[0030] 2. Preparation before coating: Put the substrate cleaned in step 1 into the vacuum chamber of magnetron sputtering, pass in the mixed gas of argon + neon + hydrogen and adjust the air pressure in the vacuum chamber, turn on the high-power pulse power supply and bias power supply, Sputtering cleaning and etching the substrate, and then pre-sputtering the Cr target;

[0031] 3. Preparation of Cr / CrN periodic layer: using high-power pulse + bias hybrid magnetron sputtering method, first pass Ar gas through the sputtering Cr target t...

specific Embodiment approach 2

[0035]Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the concentration of KOH described in step 1 is 10-50 g / L, NaHCO 3 The concentration is 20-80g / L, and the concentration of dilute HCl is 3-8mol / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Specific embodiment three: this embodiment differs from specific embodiment one or two in that: the polishing described in step one adopts metallographic sandpaper of 500#, 800#, 1000#, 1500# and 2000# to polish successively, and the polished matrix in Al 2 o 3 Under the action of polishing paste, the polishing treatment is performed for 0.5-3 hours, the ultrasonic power is 100-200W, and the ultrasonic time is 10-30 minutes. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com