Binary composite structure optical absorbent and preparation method thereof

A technology of optical absorption and binary recombination, which is applied in the field of materials and can solve the problems of affecting the optical absorption effect of the coating and the sudden change of the refractive index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

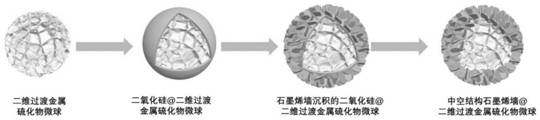

[0033] The object of the present invention is to provide a kind of preparation method of the binary composite structure light-absorbing agent that has ultra-wide band optical response from visible light to infrared band, it is characterized in that, comprises the following steps:

[0034] 1) Weigh 0.25mmol of ammonium tungstate hydrate, 10mmol of thiourea, and 0.5mmol of sodium dodecylbenzenesulfonate, and dissolve them in 50mL of water, and stir them magnetically for 20min at room temperature until they are completely dissolved;

[0035] 2) Transfer the mixed solution in step 1) to a polytetrafluoroethylene reactor and react at 220°C for 24 hours. After the reaction, cool the reactor to room temperature naturally, collect the black product by centrifugation at 5000rpm, and then use Wash with deionized water and absolute ethanol three times respectively, and dry in an oven at 60°C for 12 hours to obtain tungsten disulfide microspheres with a two-dimensional structure;

[0036]...

Embodiment 2

[0041] 1) Weigh 0.25mmol of ammonium tungstate hydrate, 10mmol of thiourea, and 1mmol of cetyltrimethylammonium bromide, and dissolve them in 50mL of water, and stir them magnetically for 20min at room temperature until they are completely dissolved;

[0042] 2) Transfer the mixed solution in step 1) to a polytetrafluoroethylene reactor and react at 220°C for 24 hours. After the reaction, cool the reactor to room temperature naturally, collect the black product by centrifugation at 5000rpm, and then use Wash with deionized water and absolute ethanol three times respectively, and dry in an oven at 60°C for 12 hours to obtain tungsten disulfide microspheres with a two-dimensional structure;

[0043] 3) Weigh 100 mg of the tungsten disulfide microsphere powder prepared in step 2), and disperse it in a mixed solvent of 350 mL of absolute ethanol and deionized water by means of ultrasonic dispersion, and the volume ratio of absolute ethanol and deionized water is 4 / 1, the time of ...

Embodiment 3

[0048] 1) Weigh 0.25mmol of ammonium molybdate hydrate, 10mmol of thiourea, and 0.5mmol of sodium dodecylbenzenesulfonate, and dissolve them in 50mL of water, and stir them magnetically for 20min at room temperature until they are completely dissolved;

[0049] 2) Transfer the mixed solution in step 1) to a polytetrafluoroethylene reactor and react at 180°C for 12 hours. After the reaction, cool the reactor to room temperature naturally, collect the black product by centrifugation at 5000rpm, and then use Wash with deionized water and absolute ethanol three times respectively, and dry in an oven at 60°C for 12 hours to obtain molybdenum disulfide microspheres with a two-dimensional structure;

[0050] 3) Weigh 100 mg of molybdenum disulfide microsphere powder prepared in step 2), and disperse it in a mixed solvent of 350 mL of absolute ethanol and deionized water by means of ultrasonic dispersion, and the volume ratio of absolute ethanol and deionized water is 4 / 1, the time o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com