High-strength antibacterial PE water supply pipe and production process thereof

A production process and technology for water supply pipes, which are applied in the field of high-strength antibacterial PE water supply pipes and their production processes, can solve the problems of poor strength and antibacterial properties of water supply pipes, and achieve excellent stability, good modification effect, and good rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

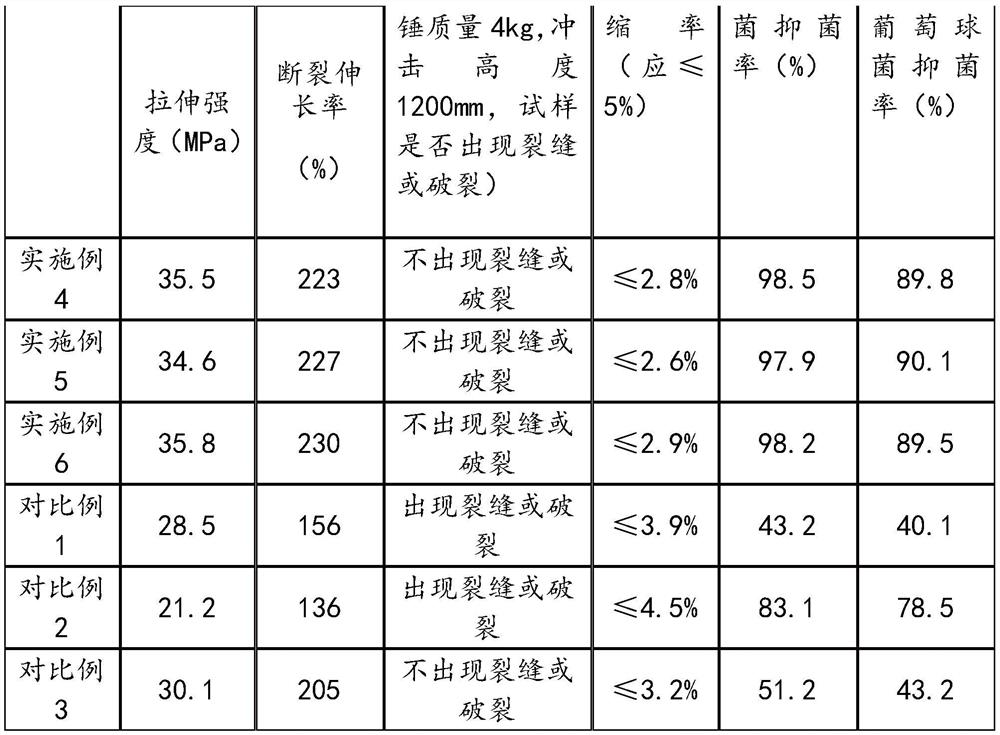

Examples

Embodiment 1

[0031] Preparation of antimicrobial composition:

[0032] Step S1, add 8.2g of tetrabutyl titanate dropwise into 20mL of absolute ethanol, stir for 50min to obtain solution a, dissolve 32mg of zinc acetate in 9mL of the mixed solution, and stir evenly to obtain solution b, and dissolve solution a Add it dropwise to solution b at a rate of 10 drops / min, stir for 1 hour, add nitric acid solution with a mass fraction of 70% to adjust the pH to 1.5, stir for 2 hours, and age for 12 hours to obtain a gel. The mixed solution is made of absolute ethanol, Glacial acetic acid is prepared according to the volume ratio of 3:1;

[0033] Step S2, put the gel in a reaction kettle, raise the temperature to 205°C for 2h, cool to room temperature, dry the obtained product at 75°C for 13h, wash twice with distilled water, and grind to obtain Zn-TiO 2 Nanoparticles;

[0034] Step S3, add 9.1g of magnesium acetate tetrahydrate and 100mL of deionized water into the three-necked flask, stir and d...

Embodiment 2

[0037] Preparation of antimicrobial composition:

[0038] Step S1, add 8.3g of tetrabutyl titanate dropwise into 22mL of absolute ethanol, stir for 55min to obtain solution a, dissolve 33mg of zinc acetate in 10mL of the mixed solution, and stir evenly to obtain solution b, and dissolve solution a Add it dropwise into solution b at a rate of 10 drops / min, stir for 1 hour, add nitric acid solution with a mass fraction of 70% to adjust the pH to 1.7, stir for 2 hours, and age for 12 hours to obtain a gel. The mixed solution is made of absolute ethanol, Glacial acetic acid is prepared according to the volume ratio of 3:1;

[0039] Step S2, put the gel in a reaction kettle, raise the temperature to 208°C for 2h, cool to room temperature, dry the obtained product at 75°C for 14h, wash twice with distilled water, and grind to obtain Zn-TiO 2 Nanoparticles;

[0040]Step S3, add 9.2g of magnesium acetate tetrahydrate and 105mL of deionized water into the three-necked flask, stir and...

Embodiment 3

[0043] Preparation of antimicrobial composition:

[0044] Step S1, add 8.4g of tetrabutyl titanate dropwise into 25mL of absolute ethanol, stir for 60min to obtain solution a, dissolve 35mg of zinc acetate in 12mL of the mixed solution, and stir evenly to obtain solution b, and dissolve solution a Add dropwise to solution b at a rate of 10 drops / min, stir for 1.5 hours, add nitric acid solution with a mass fraction of 70% to adjust the pH to 2, stir for 3 hours, and age for 12 hours to obtain a gel. The mixed solution is made of absolute ethanol , Glacial acetic acid is prepared according to the volume ratio of 3:1;

[0045] Step S2, put the gel in a reaction kettle, raise the temperature to 210°C for 2h, cool to room temperature, dry the obtained product at 75°C for 15h, wash with distilled water 3 times, and grind to obtain Zn-TiO 2 Nanoparticles;

[0046] Step S3, add 9.3g of magnesium acetate tetrahydrate and 110mL of deionized water into the three-necked flask, stir to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com