Heating element and preparation method thereof

A heating element and heating element technology, which is applied to heating element materials, ohmic resistance heating parts, tobacco, etc., can solve the problems of insufficient strength and toughness of heating elements, indirect heat conduction process, and easy fluctuation of product performance, so as to avoid the printing environment. and printing conditions, good economy, controllable material ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

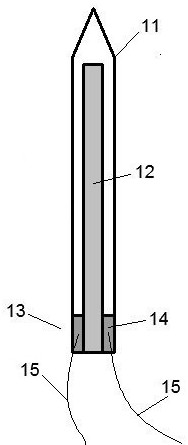

Image

Examples

Embodiment 1

[0035] The heating element S1 was prepared by the following steps:

[0036] (1) Mix Si powder and Fe powder for ball milling, the atomic ratio of Si and Fe powder is 3:1, the ball milling speed is 200rpm, the ball milling time is 10h, the ball milling atmosphere is high-purity argon, and the ball-material ratio is 10:1 to obtain metal silicide thing;

[0037] (2) The obtained metal silicide powder and non-conductive ceramic powder are mixed and ball milled, the mass percentage of the two is 0.1:1, the ball milling speed is 50rpm, the ball milling time is 6h, the ball milling medium is absolute ethanol, and the ball-to-material ratio is 5:1 ;

[0038] (3) Dry the powder slurry after ball milling in a vacuum drying oven, the vacuum degree is lower than 0.1Pa, the heating temperature is 30°C, and the drying time is 1h;

[0039] (4) Press the dried mixed powder on a press into a fluted sheet with a length of 15mm, a width of 1.2mm, and a thickness of 1mm, wherein the length of t...

Embodiment 2

[0044] Prepare the heating element S2 through the following steps:

[0045] (1) Mix Si powder and Cr powder for ball milling, the atomic ratio of Si and Cr powder is 0.5:1, the ball milling speed is 600rpm, the ball milling time is 100h, the ball milling atmosphere is high-purity argon, and the ball-to-material ratio is 30:1 to obtain metal silicide;

[0046] (2) The obtained metal silicide powder and non-conductive ceramic powder are mixed and ball milled, the mass percentage of the two is 5:1, the ball milling speed is 500rpm, the ball milling time is 48h, the ball milling medium is absolute ethanol, and the ball-to-material ratio is 10:1 ;

[0047] (3) Dry the powder slurry after ball milling in a vacuum drying oven, the vacuum degree is lower than 0.1Pa, the heating temperature is 150°C, and the drying time is 10h;

[0048] (4) Press the dried mixed powder into a grooved prism with a length of 30 mm, a width of 2 mm, and a thickness of 1.2 mm, wherein the length of the g...

Embodiment 3

[0053] Prepare the heating element S3 through the following steps:

[0054] (1) Mix Si powder with Mo and V powder for ball milling, the atomic ratio of Si, Mo and V is 5:1:1, the ball milling speed is 400rpm, the ball milling time is 42h, the ball milling atmosphere is high-purity argon, 20:1 to get metal silicide;

[0055] (2) The obtained metal silicide powder and non-conductive ceramic powder are mixed and ball milled, the mass percentage of the two is 2:1, the ball milling speed is 200rpm, the ball milling time is 32h, the ball milling medium is absolute ethanol, and the ball-to-material ratio is 7:1 ;

[0056] (3) Dry the powder slurry after ball milling in a vacuum drying oven, the vacuum degree is lower than 0.1Pa, the heating temperature is 120°C, and the drying time is 2h;

[0057] (4) Press the dried mixed powder into a cylindrical shape with a length of 25mm and a bottom diameter of 2mm with grooves on a press, wherein the length of the groove is 21mm, the width ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com