Special optical fiber with high corrosion resistance

A special optical fiber, corrosion-resistant technology, applied in the field of optical fiber, can solve the problems of poor corrosion resistance, high demand, difficult users, etc., to achieve the effect of enhanced corrosion resistance, enhanced corrosion resistance, and excellent cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

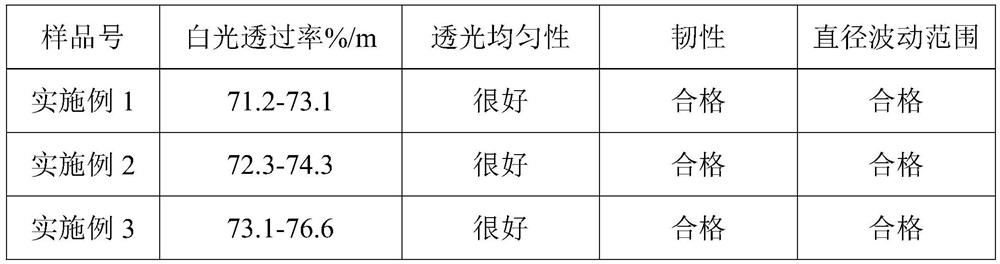

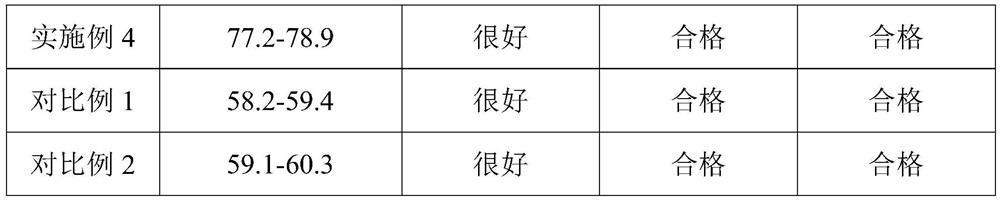

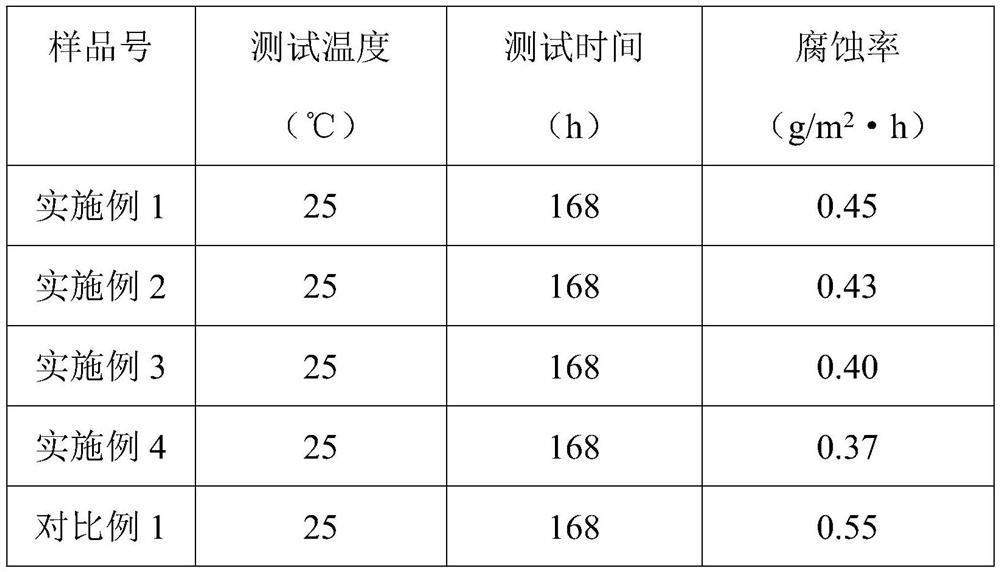

Examples

Embodiment 1

[0018] A method for preparing a highly corrosion-resistant special optical fiber, comprising the following steps:

[0019] (1) prepare graphene by Hummer method;

[0020] (2) In an argon-protected glove box, weigh 0.35g of spherical aluminum powder and 10mg of graphene and add them to a ball mill for ball milling. The ball mill speed is 300rpm / min, and the ball milling time is 20min to obtain aluminum powder@graphene;

[0021] (3) Weigh 0.2g of aluminum powder@graphene and 1g of polytetrafluoroethylene into the reaction kettle, first use nitrogen to purge the oxygen in the sample, then seal the reaction kettle, and slowly heat up to 70°C while stirring in vacuum After ℃, the temperature is no longer raised, and the temperature is controlled, and the aluminum powder@graphene is embedded in the PTFE network to obtain a fiber core prefabricated part;

[0022] (4) Both the core preform and the PTFE tube are carefully cleaned with absolute ethanol to remove any dust or impurities ...

Embodiment 2

[0024] A method for preparing a highly corrosion-resistant special optical fiber, comprising the following steps:

[0025] (1) prepare graphene by Hummer method;

[0026] (2) In an argon-protected glove box, weigh 0.36g of spherical aluminum powder and 10.5mg of graphene and add them to a ball mill for ball milling. The ball mill speed is 350rpm / min, and the ball milling time is 22min to obtain aluminum powder@graphene;

[0027] (3) Weigh 0.22g aluminum powder@graphene, 1.2g polytetrafluoroethylene and join in the reaction kettle, first use nitrogen to purge the oxygen in the sample, then seal the reaction kettle, slowly heat up while stirring in vacuum, and heat up to After 71°C, the temperature is no longer raised, and the temperature is controlled. Aluminum powder@graphene is embedded in the PTFE network to obtain a fiber core prefabricated part;

[0028] (4) Both the core preform and the PTFE tube are carefully cleaned with absolute ethanol to remove any dust or impuritie...

Embodiment 3

[0030] A method for preparing a highly corrosion-resistant special optical fiber, comprising the following steps:

[0031] (1) prepare graphene by Hummer method;

[0032] (2) In an argon-protected glove box, weigh 0.37g of spherical aluminum powder and 11mg of graphene and add them to a ball mill for ball milling. The ball mill speed is 400rpm / min, and the ball milling time is 25min to obtain aluminum powder@graphene;

[0033] (3) Weigh 0.25g aluminum powder@graphene, 1.5g polytetrafluoroethylene and join in the reaction kettle, first use nitrogen to purge the oxygen in the sample, then seal the reaction kettle, slowly heat up while stirring in vacuum, and heat up to After 72°C, the temperature will not rise, and the temperature will be controlled. Aluminum powder@graphene will be embedded in the PTFE network to obtain a fiber core prefabricated part;

[0034] (4) Both the core preform and the PTFE tube are carefully cleaned with absolute ethanol to remove any dust or impurit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com