Modified single crystal ternary cathode material based on zirconium nitrogen co-doped carbon dots and preparation method thereof

A technology for positive electrode materials and single crystal materials, which is applied in the field of modified single crystal ternary positive electrode materials based on zirconium nitrogen co-doped carbon dots and its preparation, can solve the effects of metal valence and lattice structure of positive electrode materials, carbon point agglomeration package Uneven coating, insufficient washing and coating process, etc., to achieve excellent cycle performance and discharge capacity, excellent electrical conductivity and chemical stability, and improve cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

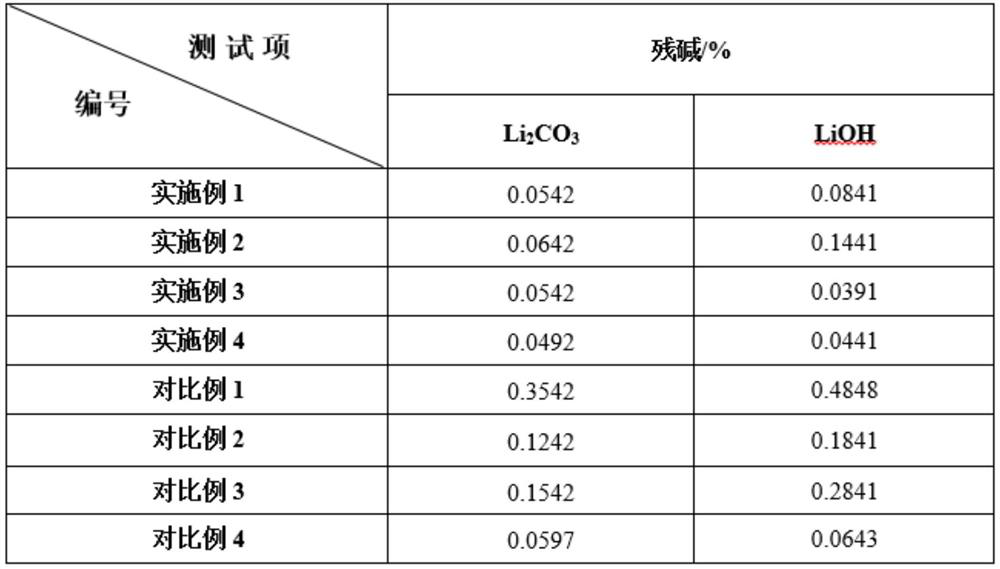

Embodiment 1

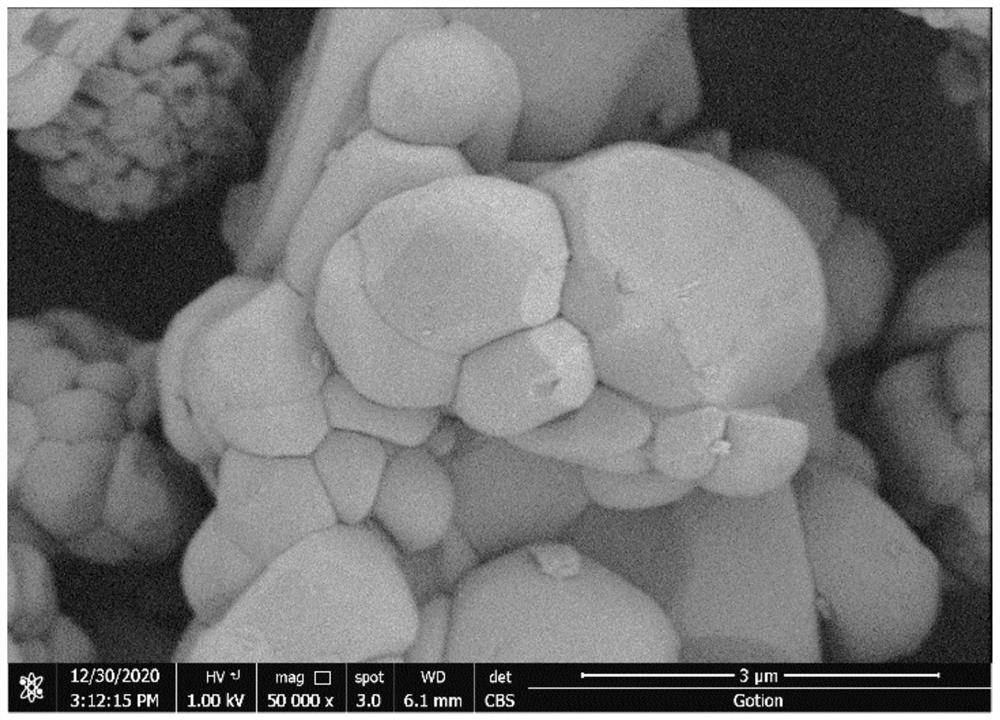

[0048] This embodiment prepares a ternary single crystal positive electrode material coated with zirconium-nitrogen co-doped carbon dots, including the following steps:

[0049] 1) Precursor Ni of ternary single crystal cathode material 0.72 Co 0.08 Mn 0.2 (OH) 2 It was mixed with lithium hydroxide at a high speed of 1:1.05 for 15 minutes, then placed in a muffle furnace, heated to 600 °C at a heating rate of 20 °C / min in an oxygen atmosphere, held for 2 hours, then heated to 860 °C, held for 12 hours , naturally cooled to below 80 °C, and the primary sintered single crystal cathode material LiNi was prepared. 0.72 Co 0.08 Mn 0.2 O 2 .

[0050] 2) 12 parts by weight of LiNi, a single-crystal positive electrode material, was sintered once 0.72 Co 0.08 Mn 0.2 O 2 Dissolve 1 part by weight of white and sugar in 7.3 parts by weight of deionized water, stir mechanically evenly, place it in a flash dryer at 110°C, dry it for 8 hours, place it in a nitrogen atmosphere and ...

Embodiment 2

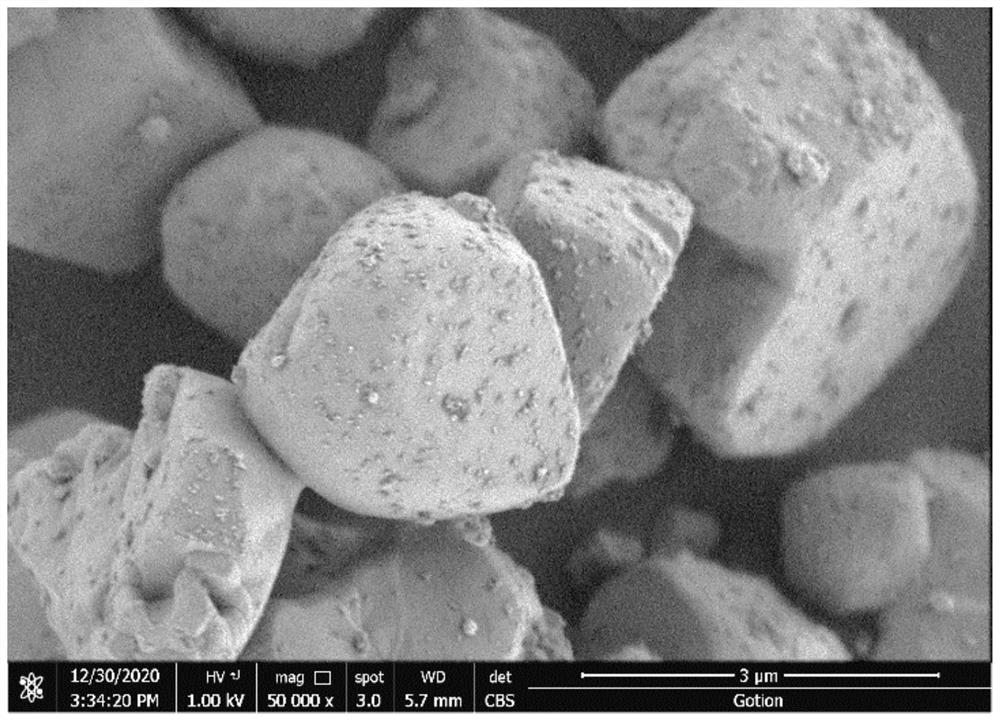

[0055] This embodiment prepares a ternary single crystal positive electrode material coated with zirconium-nitrogen co-doped carbon dots, including the following steps:

[0056] 1) Precursor Ni of ternary single crystal cathode material 0.8 Co 0.1 Mn 0.1 (OH) 2 Mixed with lithium hydroxide at a high speed of 1:1.05 for 15 minutes, placed in a muffle furnace, heated to 600 °C at a heating rate of 20 °C / min in an oxygen atmosphere, held for 2 hours, then heated to 840 °C, held for 12 hours, Naturally cooled to below 80°C to prepare primary sintered single crystal cathode material LiNi 0.8 Co 0.1 Mn 0.1 O 2 .

[0057] 2) 10 parts by weight of LiNi, a single-crystal positive electrode material, was sintered once 0.8 Co 0.1 Mn 0.1 O 2 Dissolve 1 part by weight of celery sugar in 6.2 parts by weight of deionized water, stir mechanically evenly, place it in a flash dryer at 110°C, dry it for 8 hours, place it in an argon atmosphere and heat it up to 240°C at a heating rate...

Embodiment 3

[0062] This embodiment prepares a ternary single crystal positive electrode material coated with zirconium-nitrogen co-doped carbon dots, including the following steps:

[0063] 1) Precursor Ni of ternary single crystal cathode material 0.65 Co 0.1 Mn 0.25 (OH) 2 It was mixed with lithium carbonate at a high speed of 1:1.07 for 15 minutes, placed in a muffle furnace, heated to 700°C at a heating rate of 20°C / min in a dry air atmosphere, held for 2 hours, then heated to 900°C, held for 12 hours, Naturally cooled to below 80°C to prepare primary sintered single crystal cathode material LiNi 0.65 Co 0.1 Mn 0.25 O 2 .

[0064] 2) 14 parts by weight of LiNi, a single-crystal positive electrode material, was sintered once 0.65 Co 0.1 Mn 0.25 O 2 Dissolve 1 part by weight of rhamnose in 8.4 parts by weight of deionized water, stir mechanically evenly, place it in a flash dryer at 110°C, dry it for 8 hours, place it in a nitrogen atmosphere and heat it up to 240°C at a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com