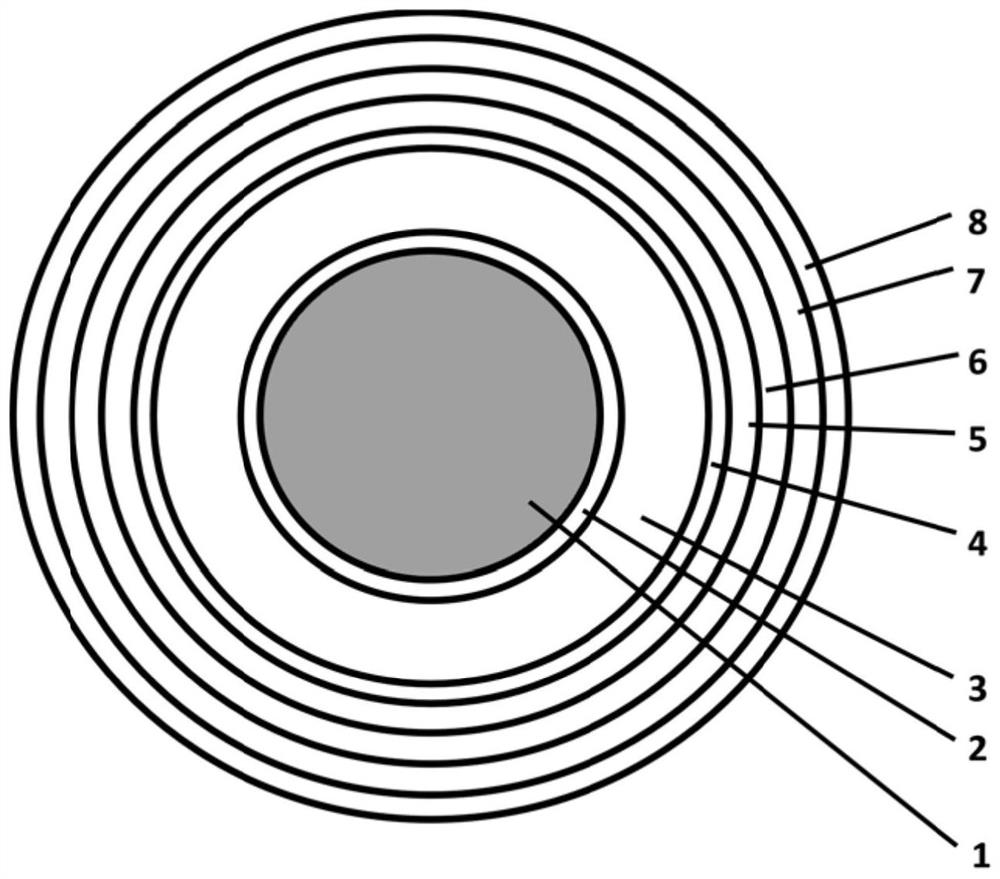

Cable with thermoplastic insulating layer

An insulating layer, thermoplastic technology, used in insulated cables, organic insulators, plastic/resin/wax insulators, etc., can solve the problem that cable products cannot meet the requirements of stable operation, and achieve low weight, strong breakdown resistance, and thin thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

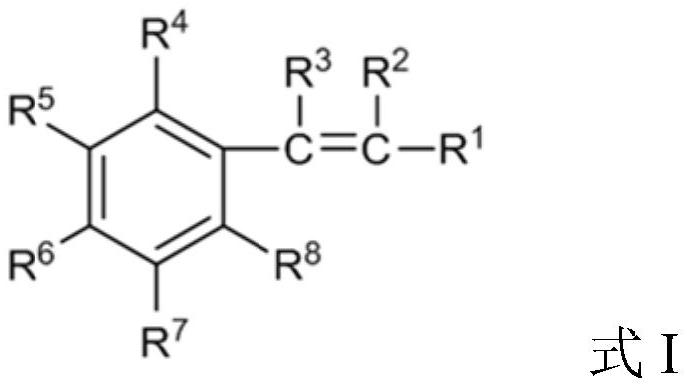

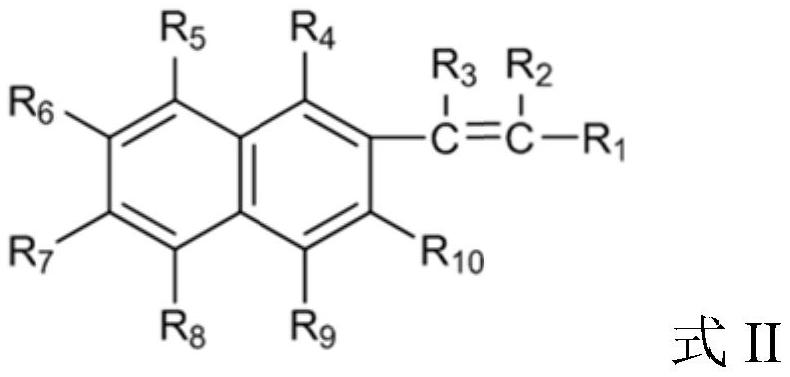

[0163] Select the basic copolymerized polypropylene powder with the following characteristics: comonomer ethylene content 18.1wt%, xylene soluble matter content 48.7wt%, soluble comonomer content 31.9wt%, soluble matter / copolymerized polypropylene The intrinsic viscosity ratio is 0.89, and the weight average molecular weight is 34.3×10 4 g / mol, at 230°C, MFR under 2.16kg load is 1.21g / 10min, Tm=143.4°C, breakdown field strength (90°C) is 236kV / mm, DC volume resistivity (90°C, 15kV / mm) It is 1.16E13Ω·m, and the fine powder smaller than 40 mesh is removed by sieving. Weigh 2.0kg of the above-mentioned basic copolymerized polypropylene powder, add it into a 10L reaction kettle with mechanical stirring, seal the reaction system, and replace oxygen with nitrogen. Add 2g of dibenzoyl peroxide and 100g of styrene, stir and mix for 60min, swell at 40°C for 4 hours, raise the temperature to 95°C, and react for 4 hours. After the reaction, the temperature was purged with nitrogen to o...

Embodiment 2

[0165] Select the basic copolymerized polypropylene powder with the following characteristics: comonomer ethylene content 14.7wt%, xylene soluble matter content 41.7wt%, soluble comonomer content 34.5wt%, soluble matter / copolymerized polypropylene The intrinsic viscosity ratio is 0.91, and the weight average molecular weight is 36.6×10 4 g / mol, at 230°C, MFR under 2.16kg load is 1.54g / 10min, Tm=164.9°C, breakdown field strength (90°C) is 248kV / mm, DC volume resistivity (90°C, 15kV / mm) It is 7.25E12Ω·m, and the fine powder smaller than 40 mesh is removed by sieving. Weigh 2.0kg of the above-mentioned basic copolymerized polypropylene powder, add it into a 10L reaction kettle with mechanical stirring, seal the reaction system, and replace oxygen with nitrogen. Add 2.8g of lauroyl peroxide and 150g of styrene, stir and mix for 60min, swell at 60°C for 2 hours, raise the temperature to 90°C, and react for 4 hours. After the reaction, the temperature was purged with nitrogen to o...

Embodiment 3

[0167] Select the basic copolymerized polypropylene powder with the following characteristics: comonomer ethylene content 20.1wt%, xylene soluble matter content 66.1wt%, soluble comonomer content 29.5wt%, soluble matter / copolymerized polypropylene The intrinsic viscosity ratio is 1.23, and the weight average molecular weight is 53.8×10 4 g / mol, MFR at 230°C, 2.16kg load is 0.51g / 10min, Tm=142.5°C, breakdown field strength (90°C) is 176kV / mm, DC volume resistivity (90°C, 15kV / mm) It is 5.63E12Ω·m, and the fine powder smaller than 40 mesh is removed by sieving. Weigh 2.0kg of the above-mentioned basic copolymerized polypropylene powder, add it into a 10L reaction kettle with mechanical stirring, seal the reaction system, and replace oxygen with nitrogen. Add 1.5g of lauroyl peroxide and 50g of styrene, stir and mix for 60min, swell at 60°C for 2 hours, raise the temperature to 85°C, and react for 4 hours. After the reaction, the temperature was purged with nitrogen to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com