Polyimide and application thereof in metal laminated plate

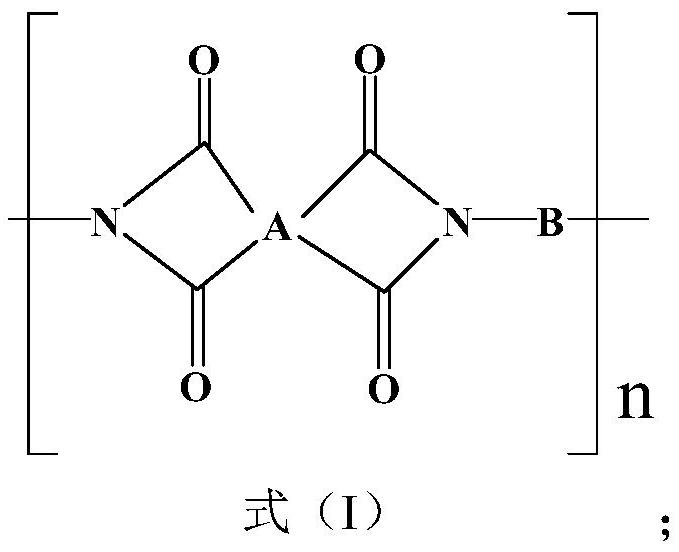

A polyimide and metal technology, which is applied to polyimide and its application in metal laminates, can solve the problems of reducing heat resistance and use temperature, large dielectric loss, and decreased adhesiveness, etc. Achieve the effect of improving bonding performance, reducing dielectric loss, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

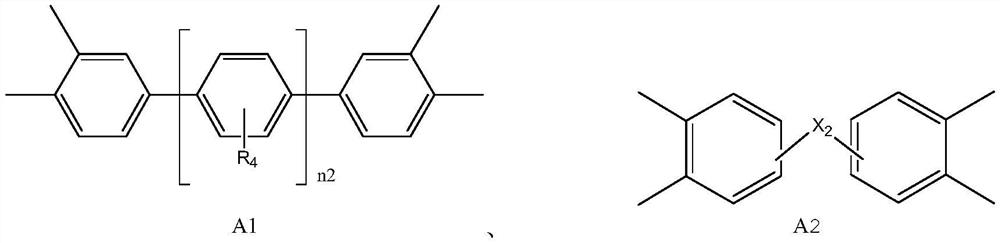

Method used

Image

Examples

Embodiment 1

[0061] Heat and dry the reaction vessel in advance, and replace it with nitrogen. After 30 minutes, add 150g of N,N-dimethylacetamide solvent, then add 11.763g of DATP and 6.7457g of BPTP, stir at 25°C until dissolved, and then Add 18.9913g of BPDA, and stir at room temperature for 12h to obtain a polyimide solution with a content of 20%.

[0062] Embodiment 2-9 and reference example 1-6

[0063] Referring to the method of polyimide in Example 1, the diamine and dianhydride were replaced with the raw materials shown in Table 1, and the addition ratio is shown in Table 1.

[0064] Table 1

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| stretching force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com