Silicon wafer feeding calibration device of photoetching machine

A calibration device and lithography machine technology, applied in the field of lithography machines, can solve the problems of inconvenient calibration work, clip damage, inconvenient automatic reset of the calibration device, etc., to achieve the effect of facilitating calibration work and preventing offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

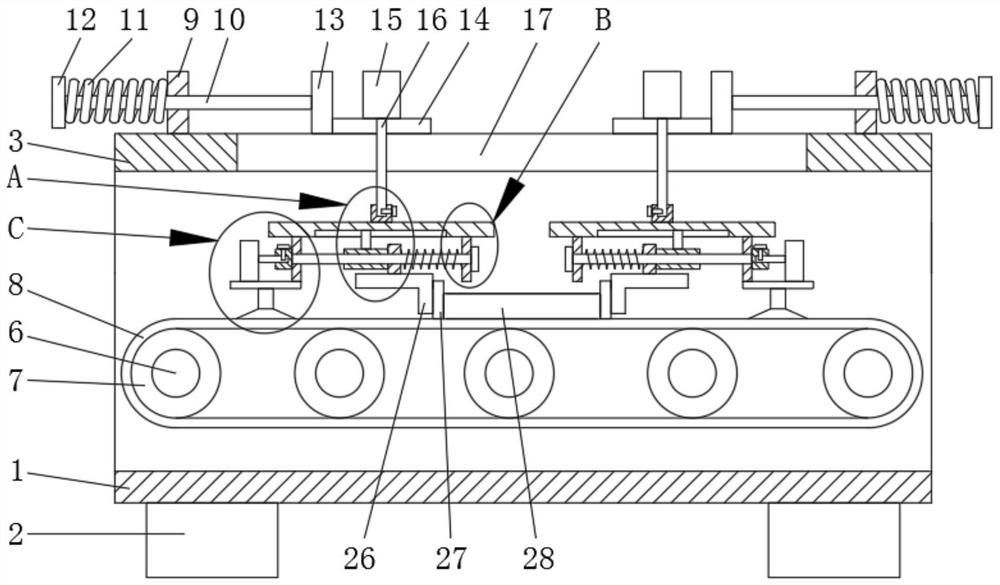

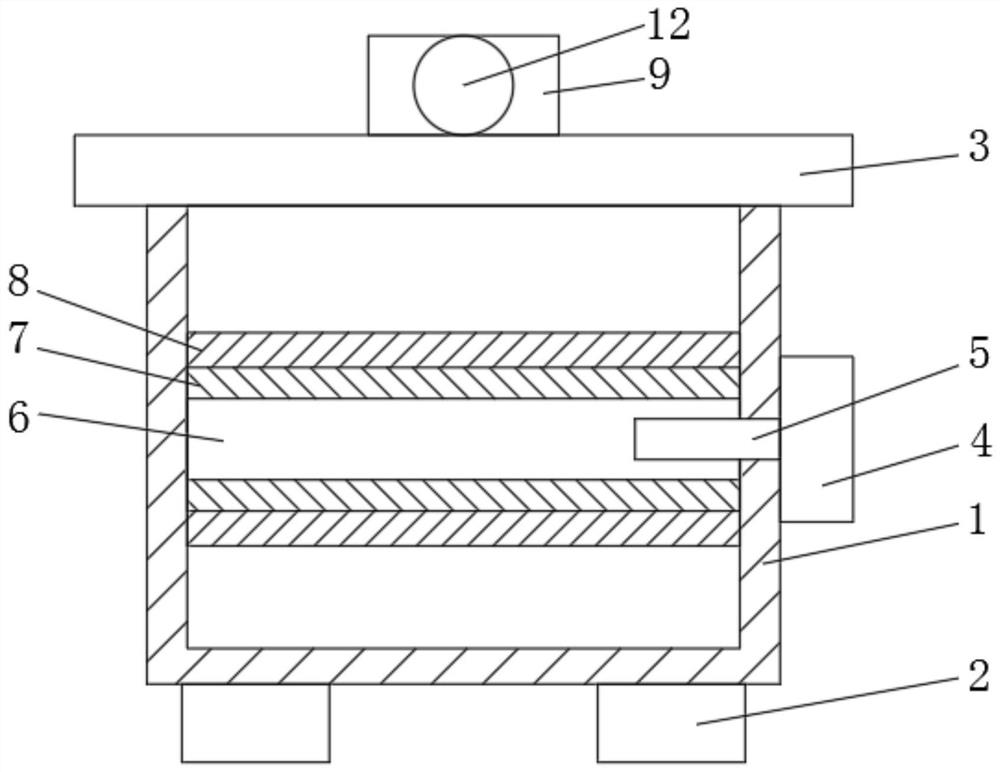

[0026] A silicon wafer feeding calibration device for a lithography machine, comprising a housing 1, a connecting seat 18, a threaded sleeve 23, a threaded rod 24, a second rotating shaft 37, and a positioning seat 38, the lower end of the housing 1 is fixedly equipped with a support seat 2 A top cover 3 is fixedly installed on the upper end of the housing 1, a first motor 4 is fixedly installed on the outer side of the housing 1, and a first rotating shaft 5 of the first motor 4 is rotationally connected with the housing 1, and the first rotating shaft The outer side of 5 is fixedly sleeved with a transmission roller 6, the outer side of the transmission roller 6 is fixedly sleeved with a rotating roller 7, the outer side of the rotating roller 7 is sleeved with a conveyor belt 8, and the outer side of the conveyor belt 8 is connected with a silicon chip. 28, the outer side of the upper cover 3 is fixedly installed with a fixed block 9, the inside of the fixed block 9 is slida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com