High-temperature-resistant microcapsule lubricant, preparation method and application thereof, and water-based drilling fluid

A technology of microcapsules and lubricants, which is applied in the field of drilling fluid lubricants, can solve the problems of easy decomposition, inability to adapt to the high temperature environment in the well, and poor temperature resistance, and achieve uniform heating, excellent thermal conductivity and lubrication performance, and improve load resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The first aspect of the present invention provides a kind of preparation method of anti-high temperature microcapsule lubricant, this method comprises:

[0019] (1) mixing a prepolymer solution made of formaldehyde and urea with carbon microspheres to obtain a wall material mixture;

[0020] (2) preparing emulsifier, ionic liquid, lubricating oil, extreme pressure antiwear agent and water to obtain compound emulsion;

[0021] (3) In the presence of a curing agent, the wall material mixture and the compound emulsion are reacted under acidic conditions, and the product is left standing, filtered and dried to obtain a high temperature resistant microcapsule lubricant.

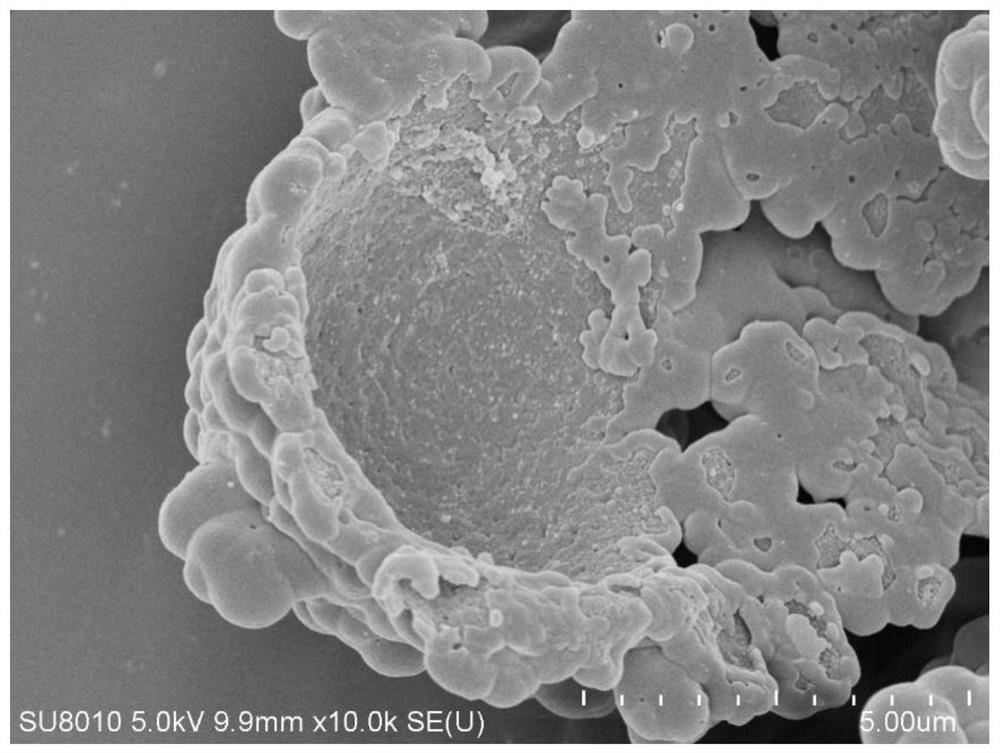

[0022] In the present invention, the carbon microspheres prepared by the hydrothermal reaction method are added to the resin prepolymer obtained by in-situ polymerization of formaldehyde and urea, and the modified prepolymer mixed liquid is obtained after ultrasonic dispersion. Under the action of the curi...

Embodiment 1

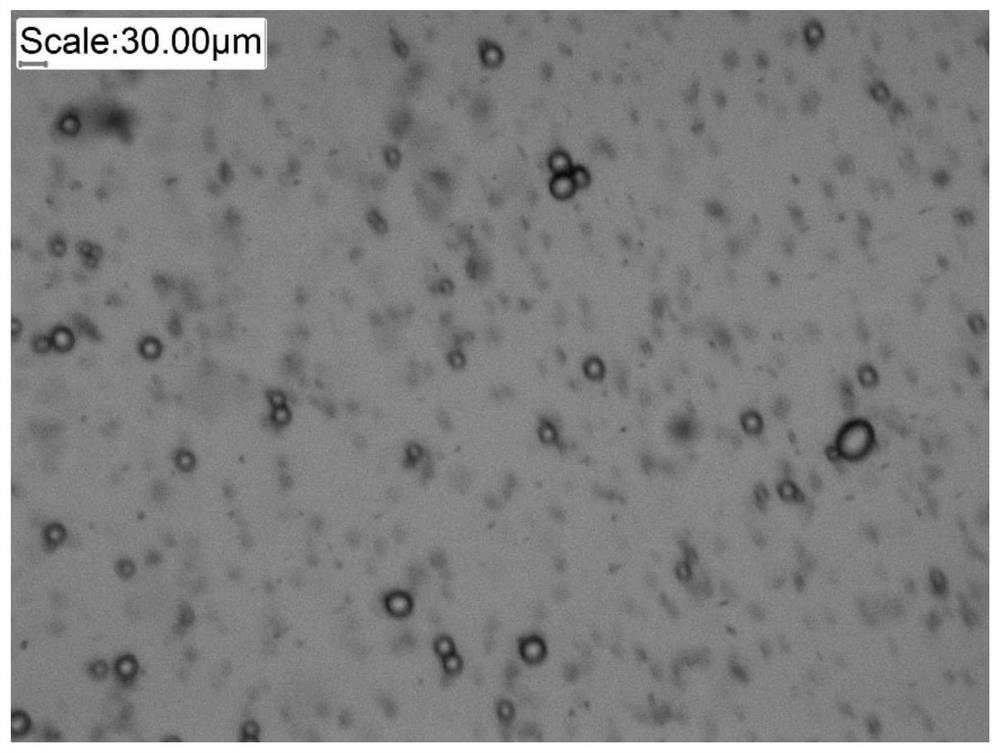

[0072] (1) Add 100g of glucose to 1L of deionized water, raise the temperature to 90°C, stir until completely dissolved, then transfer the solution to a hydrothermal reaction kettle, after 180°C hydrothermal reaction for 8 hours, let the product stand and cool to room temperature , remove the supernatant, and air-dry the brown precipitate at 100°C for 4 hours to obtain carbon microspheres; the measured average particle size is 317nm;

[0073] (2) Weigh 45g of 40% formaldehyde aqueous solution and 24g of urea into a three-necked flask, heat it in a water bath to 60°C while stirring at 800r / min, add 10% sodium hydroxide solution dropwise to make the pH of the reaction system 9, and continue the reaction for 1h , cooled to room temperature to obtain a transparent and viscous prepolymer solution, add 14g of carbon microspheres, and ultrasonically disperse for 30 minutes to obtain a wall material mixture;

[0074] (3) Weigh 1.97g of Tween-80 and 48g of deionized water into a beaker...

Embodiment 2

[0079] (1) Add 50g of glucose to 1L of deionized water, raise the temperature to 90°C, stir until completely dissolved, then transfer the solution to a hydrothermal reaction kettle, after 240°C hydrothermal reaction for 28 hours, let the product stand and cool to room temperature , remove the supernatant, and air-dry the brown precipitate at 100°C for 4 hours to obtain carbon microspheres; the measured average particle size is 676nm;

[0080] (2) Weigh 45g of 40% formaldehyde aqueous solution and 18g of urea into a three-necked flask, heat it in a water bath to 95°C while stirring at 1600r / min, add 10% sodium hydroxide solution dropwise to make the pH of the reaction system 9, and continue the reaction for 1h , cooled to room temperature to obtain a transparent and viscous prepolymer solution, add 6g of carbon microspheres, and ultrasonically disperse for 30 minutes to obtain a wall material mixture;

[0081] (3) Weigh 3.09g of Tween-80 and 48g of deionized water into a beaker...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com