Epoxy resin coating and preparation method and application thereof

An epoxy resin coating, epoxy resin technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings and other directions, can solve the problems of low construction efficiency, peeling, low decontamination rate of nuclear pollutants, etc., to improve radiation resistance Illumination ability, increased crosslink density, excellent tolerance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

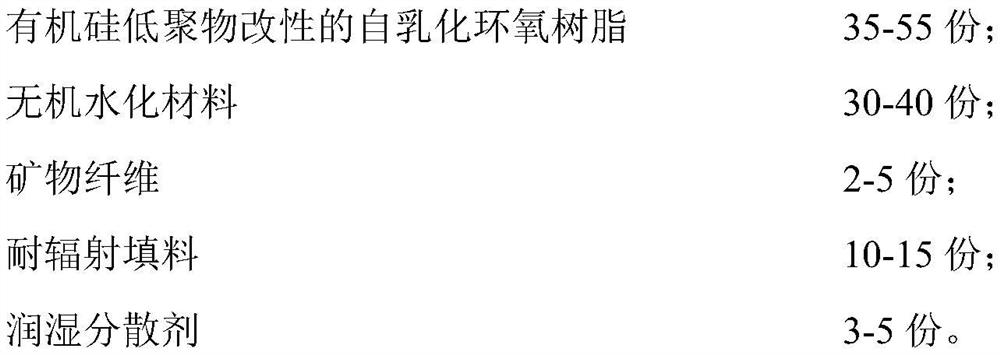

[0043] This embodiment provides a kind of epoxy resin paint, comprises base material and amine curing agent, and described base material raw material is composed of:

[0044]

[0045]

[0046] The preparation method of the self-emulsifying epoxy resin modified by the organosilicon oligomer comprises the steps:

[0047]1) Mix γ-glycidyl etheroxypropyltrimethoxysilane (KH560), dimethyldiethoxysilane, and water for hydrolysis, the hydrolysis temperature is 60°C, and the hydrolysis time is 4h. The γ-glycidol Etheroxypropyltrimethoxysilane: dimethyldiethoxysilane: the mass ratio of water is 100:20:10 to obtain the organosilicon oligomer (the number average molecular weight of the organosilicon oligomer is 500- 1000);

[0048] 2) Silicone oligomer and self-emulsifying epoxy resin (self-emulsifying epoxy resin is self-emulsifying bisphenol A epoxy resin with epoxy equivalent 188-200, purchased from Allnex Company, model 147W) are mixed and heated for modification , the modifi...

Embodiment 2

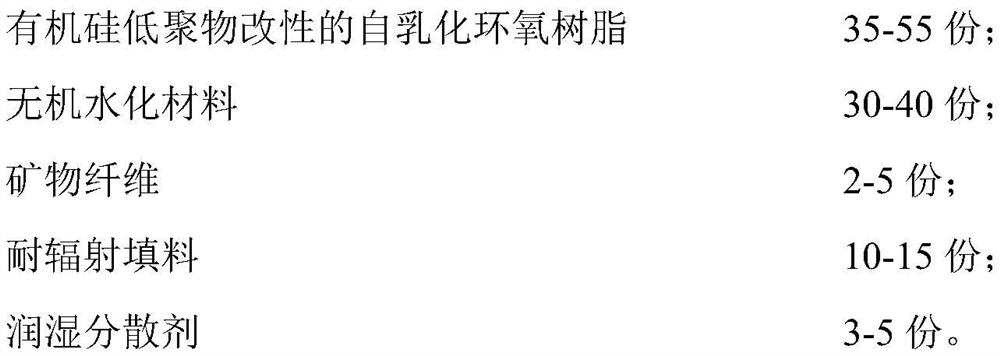

[0056] This embodiment provides a kind of epoxy resin paint, comprises base material and amine curing agent, and described base material raw material is composed of:

[0057]

[0058] The preparation method of the self-emulsifying epoxy resin modified by the organosilicon oligomer comprises the steps:

[0059] 1) Mix γ-glycidyl etheroxypropyltrimethoxysilane (KH560), diphenyldiethoxysilane, and water for hydrolysis. The hydrolysis temperature is 65°C, and the hydrolysis time is 4 hours. The γ-glycidol Etheroxypropyltrimethoxysilane: diphenyldiethoxysilane: the mass ratio of water is 100:20:10 to obtain the organosilicon oligomer (the number average molecular weight of the organosilicon oligomer is 600- 1000);

[0060] 2) Silicone oligomer and self-emulsifying epoxy resin (self-emulsifying epoxy resin is a self-emulsifying novolac epoxy resin with a functionality of 2.3 and an epoxy equivalent of 172-182, purchased from Huntsman Company, model PY340-2) Mixing and heating f...

Embodiment 3

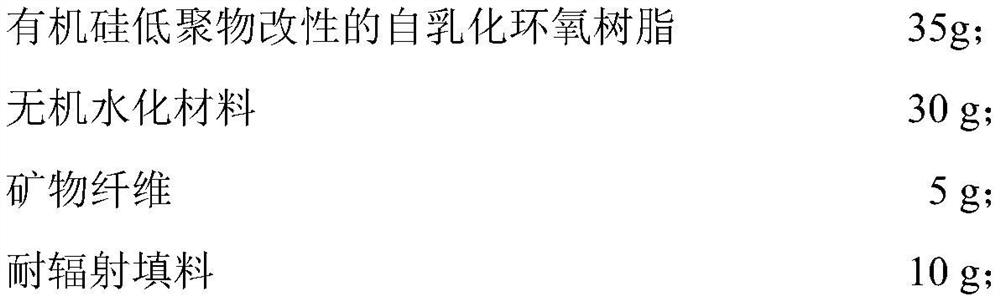

[0068] This embodiment provides a kind of epoxy resin paint, comprises base material and amine curing agent, and described base material raw material is composed of:

[0069]

[0070] The preparation method of the self-emulsifying epoxy resin modified by the organosilicon oligomer comprises the steps:

[0071] 1) Mix γ-glycidyl etheroxypropyltrimethoxysilane (KH560), dimethyldiethoxysilane, and water for hydrolysis, the hydrolysis temperature is 55°C, and the hydrolysis time is 5h. The γ-glycidol Etheroxypropyltrimethoxysilane: dimethyldiethoxysilane: the mass ratio of water is 100:15:15, to obtain the organosilicon oligomer (the number average molecular weight of the organosilicon oligomer is 600- 800);

[0072] 2) Silicone oligomer and self-emulsifying epoxy resin (self-emulsifying epoxy resin is self-emulsifying bisphenol A epoxy resin with epoxy equivalent 188-200, purchased from Allnex Company, model 147W) are mixed and heated for modification , the modification temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com