Flexible fireproof cable production process

A fireproof cable and production process technology, applied in the direction of insulated cables, bendable cables, cable/conductor manufacturing, etc., can solve problems such as hidden dangers, fireproof cables are not in place, cables lose fire protection, environmental protection, etc., to ensure safe operation, Good thermal insulation, hazard reduction effect for personnel and electrical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

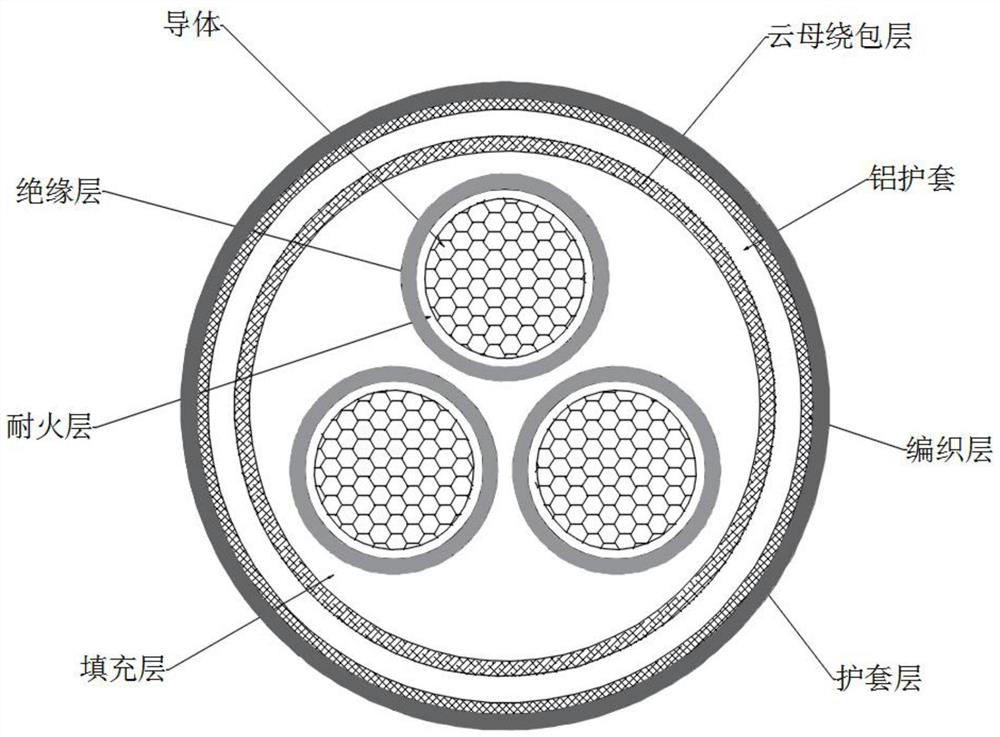

[0026] A kind of flexible fireproof cable production process comprises the following steps:

[0027] S1. Drawing and annealing the copper rod to obtain a copper wire with a diameter of 0.5 mm, and then twisting 30 copper wires to form a copper conductor;

[0028] S2, wrapping the flame-retardant composite tape outside the conductor to form a fire-resistant layer, and the wrapping overlap rate is controlled at 25%, and then extruding ethylene-propylene rubber outside the fire-resistant layer to form an insulating layer to obtain a conductive cable core;

[0029] S3. Gather at least two conductive cable cores and then fill the periphery with aluminum hydroxide, magnesium hydroxide, anhydrous magnesium carbonate or layered sodium silicate to obtain a filling layer;

[0030] S4. Wrapping the mica tape outside the filling layer to obtain a mica wrapping layer, the wrapping overlap rate is controlled at 25%, and then extruding ceramic silicone rubber outside the mica wrapping layer ...

Embodiment 2

[0037] A kind of flexible fireproof cable production process comprises the following steps:

[0038] S1. Drawing and annealing the copper rod to obtain a copper wire with a diameter of 2mm, and then twisting 15 copper wires to form a copper conductor;

[0039] S2. Wrapping the outside of the conductor with a flame-retardant composite tape to form a refractory layer, the wrapping overlap rate is controlled at 20%, and then extruding ethylene-propylene rubber on the outside of the refractory layer to form an insulating layer to obtain a conductive cable core;

[0040] S3. Gather at least two conductive cable cores and then fill the periphery with aluminum hydroxide, magnesium hydroxide, anhydrous magnesium carbonate or layered sodium silicate to obtain a filling layer;

[0041] S4. Wrapping the mica tape outside the filling layer to obtain a mica wrapping layer, the wrapping overlap rate is controlled at 20%, and then extruding ceramic silicone rubber outside the mica wrapping l...

Embodiment 3

[0048] A kind of flexible fireproof cable production process comprises the following steps:

[0049] S1. Drawing and annealing the copper rod to obtain a copper wire with a diameter of 2 mm, and then twisting 10 copper wires to form a copper conductor;

[0050] S2, wrapping the flame-retardant composite tape outside the conductor to form a fire-resistant layer, and the wrapping overlap rate is controlled at 25%, and then extruding ethylene-propylene rubber outside the fire-resistant layer to form an insulating layer to obtain a conductive cable core;

[0051] S3. Gather at least two conductive cable cores and then fill the periphery with aluminum hydroxide, magnesium hydroxide, anhydrous magnesium carbonate or layered sodium silicate to obtain a filling layer;

[0052] S4. Wrapping the mica tape outside the filling layer to obtain a mica wrapping layer, the wrapping overlap rate is controlled at 25%, and then extruding ceramic silicone rubber outside the mica wrapping layer to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com