A β-cyclodextrin polyrotaxane with accurate intercalation amount, preparation method and application thereof

A technology of cyclodextrin and polyrotaxane, which is applied in the field of supramolecular polymers, can solve the problems of long reaction routes, differences in cavity adaptability, and lack of widespread attention, and achieve a wide range of options, easy degradation, and abundant The effect of structure type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

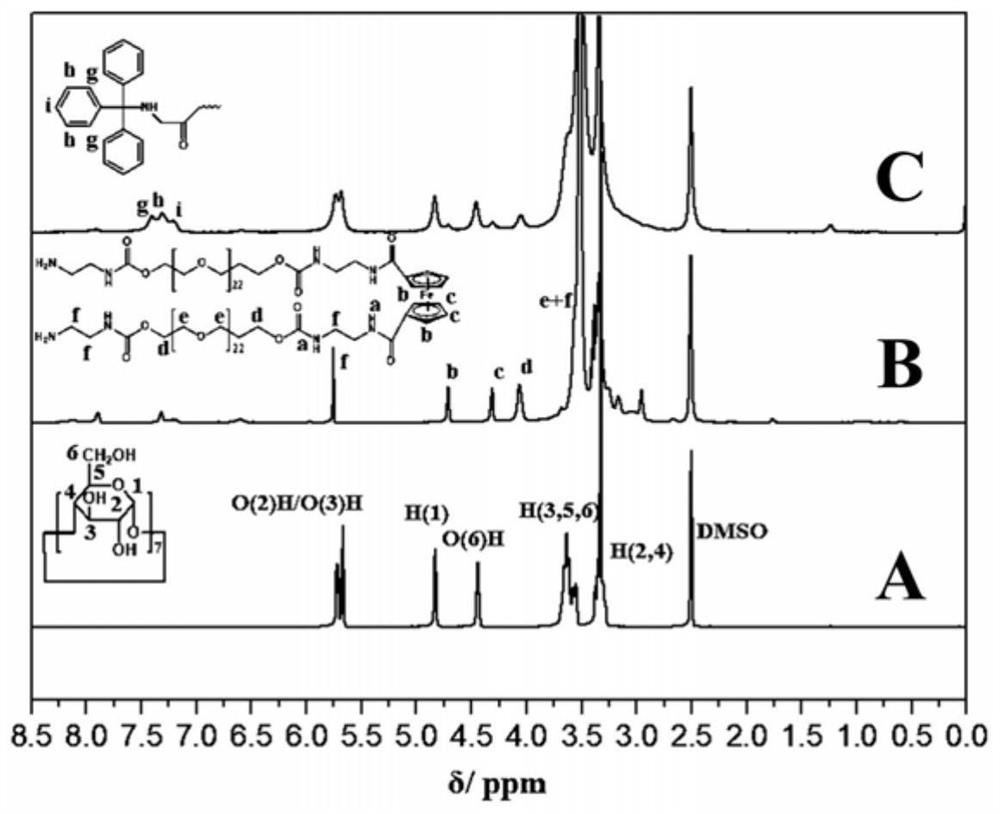

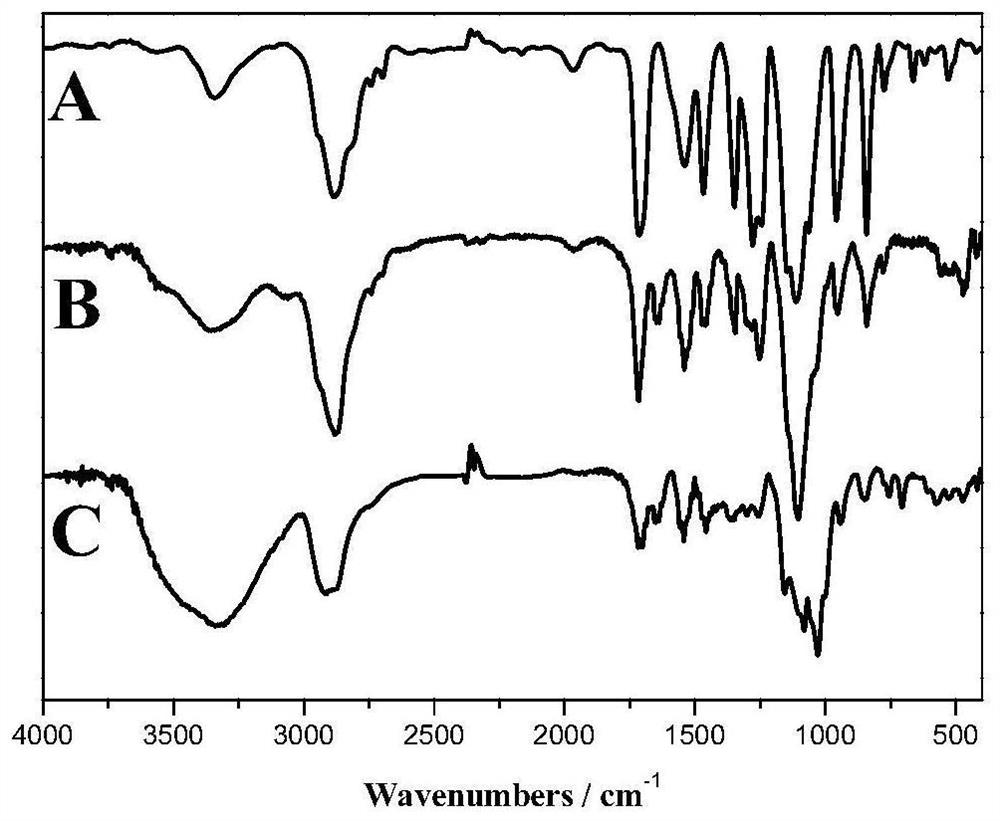

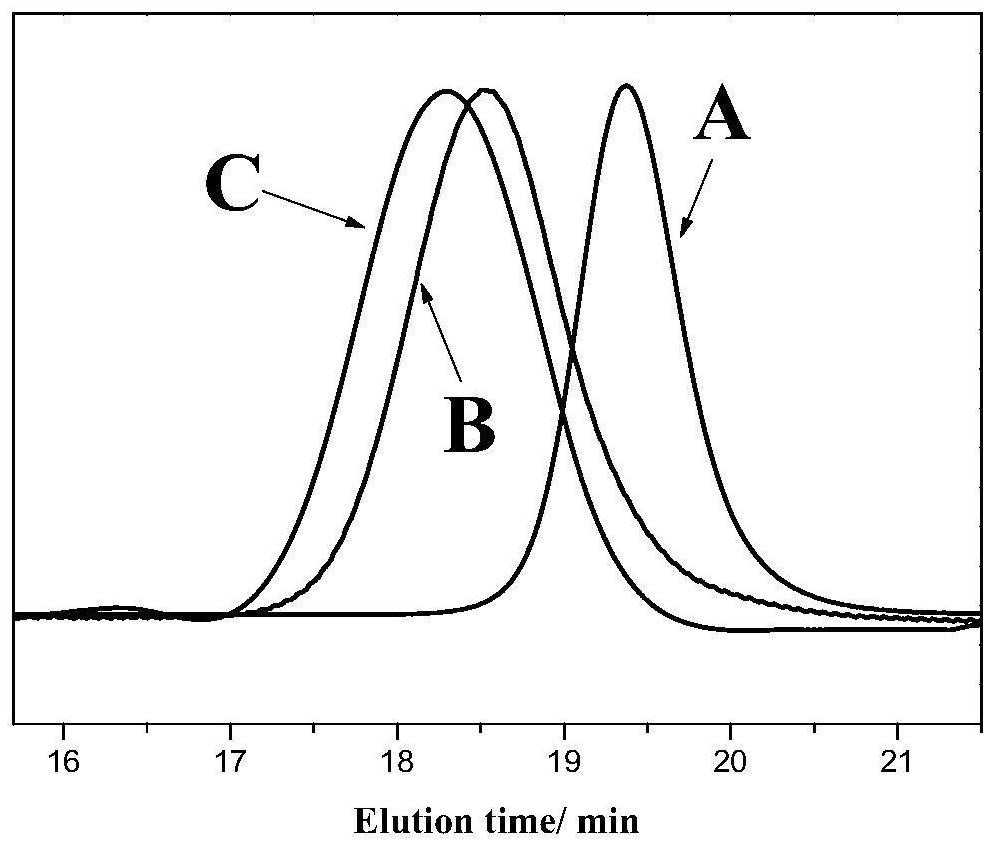

[0082] A preparation method of β-CD[3]PR, the method steps are as follows:

[0083] (1) In the reaction vessel, add 1 part of PEG1000, 8.0 parts of CDI and dry THF equivalent to 8 times the mass of PEG1000, mix well under nitrogen protection, and react at 25°C for 24h. Add 40 parts of ethylenediamine, continue to react at 25°C for 24h under nitrogen protection, concentrate the obtained solution by rotary evaporation, add dichloromethane equivalent to 15 times PEG1000 parts by mass, mix well, pour into the liquid separator, and then add equivalent to 1000 parts by mass of PEG. 0.2 times the volume of dichloromethane saturated brine was fully shaken for washing, and after standing for 5 min, the organic phase was separated, and the washing was repeated 4 times. Add 20 parts of anhydrous sodium sulfate and shake well, filter the retained liquid phase after 5 minutes, evaporate and concentrate, then precipitate in 50 parts of glacial ether, collect the precipitate and vacuum dry t...

Embodiment 2

[0098] A preparation method of β-CD[3]PR, the method steps are as follows:

[0099] (1) In the reaction vessel, add 1 part of PEG2000, 10.0 parts of CDI and dry THF equivalent to 6 times the mass of PEG2000, mix uniformly under nitrogen protection, and react at 30°C for 24h. Add 50 parts of ethylenediamine, continue to react at 30°C for 24h under nitrogen protection, concentrate the obtained solution by rotary evaporation, add dichloromethane equivalent to 17 times the mass of PEG 2000, mix evenly, pour into the liquid separator, and then add an amount equivalent to 2000 parts by mass 0.2 times the volume of dichloromethane saturated brine was fully shaken for washing, and after standing for 5 min, the organic phase was separated, and the washing was repeated 4 times. Add 20 parts of anhydrous sodium sulfate to fully shake, filter and retain the liquid phase after 5 minutes, evaporate and concentrate, and then precipitate in 50 parts of glacial ether, collect the precipitate a...

Embodiment 3

[0111] A preparation method of β-CD[3]PR, the method steps are as follows:

[0112] (1) with step (1) of embodiment 1.

[0113] (2) with step (2) of embodiment 1.

[0114] (3) 0.1 part of the shaft polymer and 0.8 part of β-CD were mixed and stirred in deionized water equivalent to 80 times the mass fraction of β-CD at 35°C for 5 days, and dried by blasting at 80°C for 24h, β-CD-PPR was obtained.

[0115] (4) In the reaction vessel, add 0.1 part of the β-CD-PPR, 0.8 part of tritylglycine, 0.85 part of BOP, 0.85 part of N,N-diisopropylethylamine, equivalent to β-CD- PPR 15 mass parts of THF and CH in a volume ratio of 1:1 3 The mixed solvent of CN was stirred at 25 °C for 24 h, and the obtained suspension was subjected to solid-liquid separation. The solid was washed 3 times with 1.5 parts of THF, 2 times with 1.5 parts of acetone, and once with 1.5 parts of methanol. In 1 part of DMSO, 2000D cellulose dialysis bag was used for dialysis against deionized water for 6 days, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com