Underground waterproof engineering construction method

A technology for engineering construction and underground waterproofing, applied in water conservancy projects, infrastructure projects, artificial islands, etc. Garbage and other problems, to achieve the effect of reducing dust pollution and construction waste, improving waterproof effect, and efficient construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

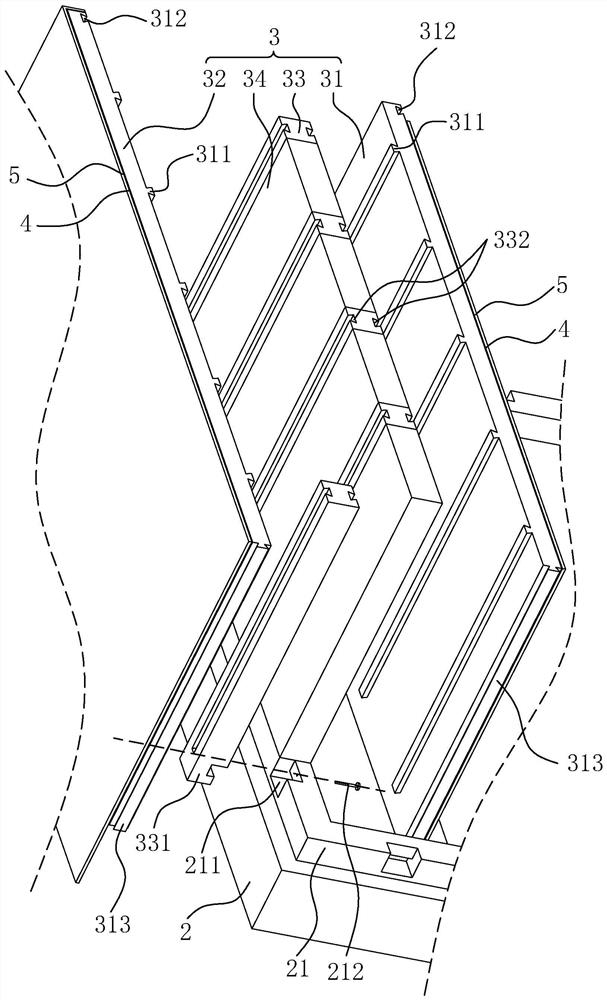

[0046] The following is attached Figure 1-4 The application is described in further detail.

[0047] The embodiment of the present application discloses an underground waterproof engineering construction method.

[0048] A construction method for underground waterproofing, comprising the following steps:

[0049] S1. Prefabricated foundation 2:

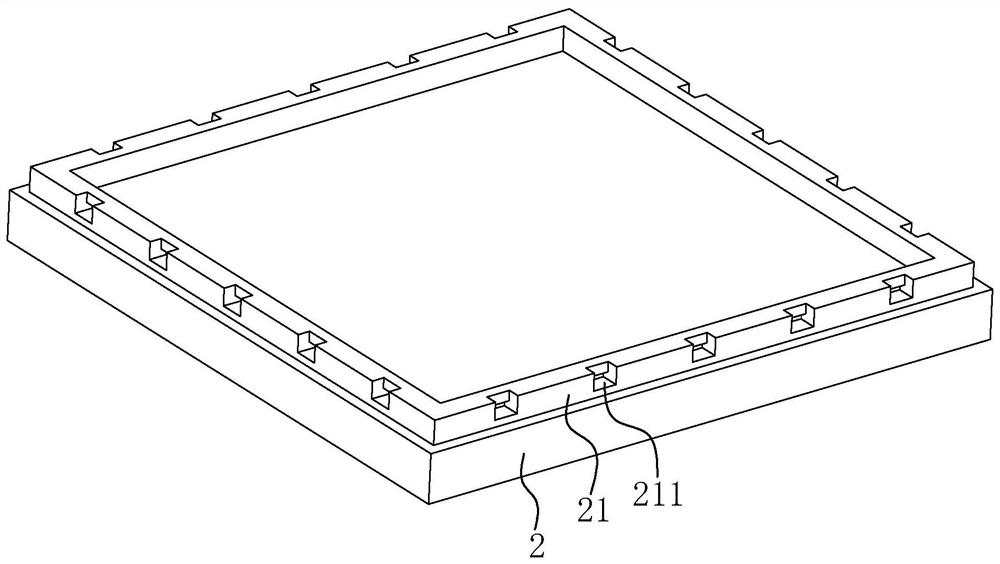

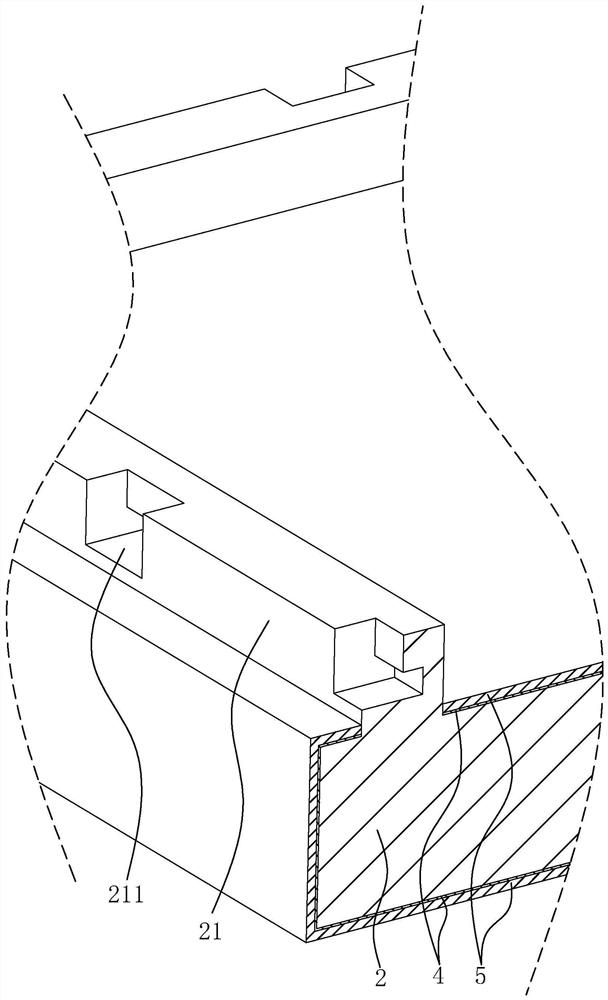

[0050] refer to figure 1 , Before construction, prefabricate the foundation 2 in the workshop. Concrete is poured in the formwork according to the design size, and the foundation 2 is formed after the concrete is solidified. A crossbeam 21 is integrally poured on the top surface of the foundation 2. The crossbeam 21 is a rectangular frame. The crossbeam 21 is located near the edge of the foundation 2 and has a distance from the side of the foundation 2. A plurality of installation slots 211 are provided on the side surfaces, and the installation slots 211 are L-shaped and run through the top surface of the beam 21 .

[0051] re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com