Preparation method of fast-curing high-wear-resistance impact-resistance water-based acrylate coating material

A water-based acrylate, fast-curing technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor dispersion stability against strong mechanical force, large baking energy consumption, and long time required to achieve thermal stability. Good stability, fast drying and improved impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

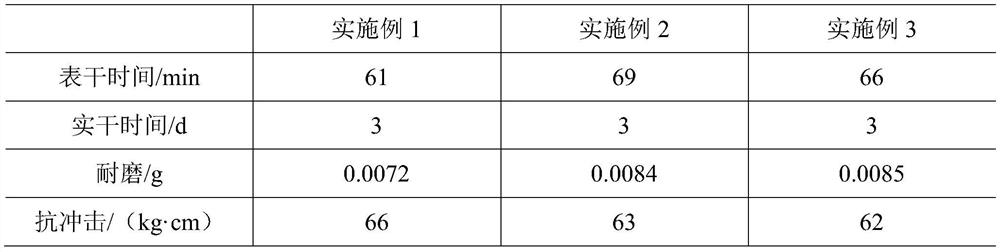

Embodiment 1

[0039] A fast curing high abrasion and impact resistant waterborne acrylic coating:

[0040] 1) Mix lauryl methacrylate and water-based polyurethane-modified acrylate at a mass ratio of 1.6:1, add deionized water 6 times the mass of water-based polyurethane-modified acrylate and stir evenly, and distill the resulting mixture to a solid content of 60% , adjust the pH to 8 to obtain a water-based polyurethane-modified acrylate composite emulsion for later use.

[0041] 2) Mix and stir nano silicon dioxide, trifluoroethyl methacrylate and silane coupling agent KH550 evenly, then add absolute ethanol and 15% ammonia water to it, heat up to 60°C and keep warm for 3 hours (the mass ratio 1:1:0.4:6:5), then add deionized water 2.6 times the mass of trifluoroethyl methacrylate and stir evenly to obtain a modified silica-doped trifluoroethyl methacrylate solution.

[0042]3) In parts by weight, mix 70 parts of water-based polyurethane modified acrylate composite emulsion with 50 parts...

Embodiment 2

[0044] A fast curing high abrasion and impact resistant waterborne acrylic coating:

[0045] 1) Mix lauryl methacrylate and water-based polyurethane-modified acrylate at a mass ratio of 1.6:1, add deionized water six times the mass of water-based polyurethane-modified acrylate for emulsification, and distill the obtained emulsion to a solid content of 60 %, adjust the pH to 8 to obtain a water-based polyurethane-modified acrylate composite emulsion for subsequent use.

[0046] 2) Mix and stir nano silicon dioxide, trifluoroethyl methacrylate and silane coupling agent KH550 evenly, then add absolute ethanol and 15% ammonia water to it, heat up to 60°C and keep warm for 3 hours (the mass ratio 1:1:0.4:6:5), then add deionized water 2.6 times the mass of trifluoroethyl methacrylate and stir evenly to obtain a modified silica-doped trifluoroethyl methacrylate solution.

[0047] 3) In parts by weight, mix 60 parts of water-based polyurethane modified acrylate composite emulsion wi...

Embodiment 3

[0049] A fast curing high abrasion and impact resistant waterborne acrylic coating:

[0050] 1) Mix lauryl methacrylate and water-based polyurethane-modified acrylate at a mass ratio of 1.6:1, add deionized water six times the mass of water-based polyurethane-modified acrylate for emulsification; distill the obtained emulsion to a solid content of 60 %, adjust the pH to 8 to obtain a water-based polyurethane-modified acrylate composite emulsion for subsequent use.

[0051] 2) Mix and stir nano silicon dioxide, trifluoroethyl methacrylate and silane coupling agent KH550 evenly, then add absolute ethanol and 15% ammonia water to it, heat up to 60°C and keep warm for 3 hours (the mass ratio 1:1:0.4:6:5), then add deionized water 2.6 times the mass of trifluoroethyl methacrylate and stir evenly to obtain a modified silica-doped trifluoroethyl methacrylate solution.

[0052] 3) In parts by weight, mix 75 parts of water-based polyurethane modified acrylate composite emulsion with 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com