A kind of spraying type putty and its preparation method and application

A technology of putty and main ash, which is used in coatings, devices for coating liquid on the surface, filling slurry, etc. The effect of improving construction efficiency and reducing operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the highly elastic unsaturated polyester resin is as follows: in parts by weight, 23 parts of diethylene glycol, 5 parts of ethylene glycol, 5 parts of linolenic acid, 8 parts of tetrahydrophthalic anhydride, 12 parts of sebacic acid Add parts into the reaction kettle, raise the temperature to 188°C~190°C, keep the temperature for 3~4 hours, and check the acid value of 50~60mgKOH / g, then cool down to below 180°C; then add 10 parts of maleic anhydride, at 1.5 Raise the temperature to 188°C~190°C within ~2 hours, continue the heat preservation reaction, and after the acid value is detected to be 50~55mgKOH / g, carry out the vacuum reaction, control the vacuum degree to -0.080~-0.085Mpa, and keep the kettle temperature at 188°C~190 ℃, the vacuuming time is 1.0-1.5 hours, after the acid value is detected to be 35-40 mgKOH / g, the temperature is lowered to 120 ℃, and 2 parts of hexamethylene diisocyanate is added dropwise in 20-30 minutes, and the drop...

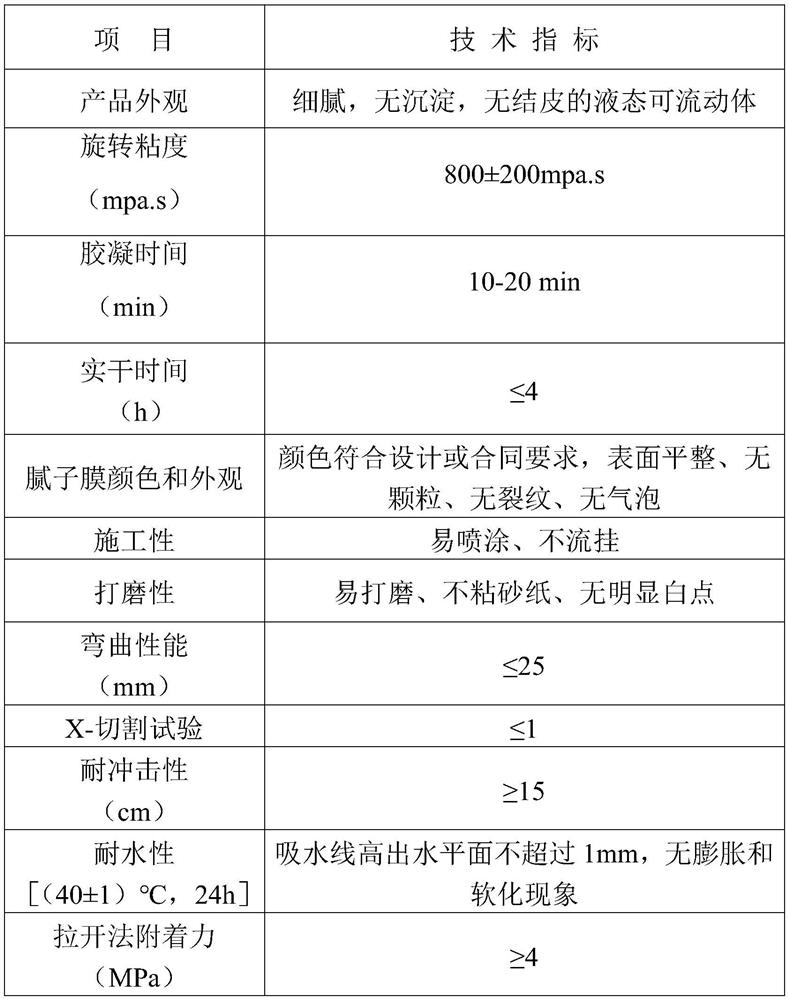

Embodiment 1

[0061] A spray-on putty, including main ash and curing agent, the weight ratio of main ash and curing agent is 100:2. The curing agent is cyclohexanone peroxide. The main ash includes the following components in parts by weight: 38 parts of high elastic unsaturated polyester resin, 17 parts of air-drying unsaturated polyester resin, 4.0 parts of cobalt isooctanoate, 0.25 parts of dimethylaniline, moistening 2.0 parts of wet dispersant, 2.5 parts of titanium dioxide, 9 parts of organic bentonite, 2.0 parts of fumed silica, 7 parts of 1250 mesh talc powder, and 12 parts of 800 mesh talc powder.

[0062] The preparation process of described spray type putty is:

[0063] S1, preparation of highly elastic unsaturated polyester resin

[0064] In parts by weight, add 23 parts of diethylene glycol, 5 parts of ethylene glycol, 5 parts of linolenic acid, 8 parts of tetrahydrophthalic anhydride, and 12 parts of sebacic acid into the reaction kettle, raise the temperature to 188°C-190°C...

Embodiment 2

[0071] A spray-on putty, including main ash and curing agent, the weight ratio of main ash and curing agent is 100:2. The curing agent is cyclohexanone peroxide. The main ash includes the following components in parts by weight: 35 parts of highly elastic unsaturated polyester resin, 18 parts of air-drying unsaturated polyester resin, 5 parts of cobalt isooctanoate, 0.22 part of dimethylaniline, moistening 2.5 parts of wet dispersant, 3 parts of titanium dioxide, 8.5 parts of organic bentonite, 1.8 parts of fumed silica, 5 parts of 1250 mesh talc powder, and 11 parts of 800 mesh talc powder.

[0072] The preparation process of described spray type putty is:

[0073] S1, preparation of highly elastic unsaturated polyester resin

[0074] In parts by weight, add 23 parts of diethylene glycol, 5 parts of ethylene glycol, 5 parts of linolenic acid, 8 parts of tetrahydrophthalic anhydride, and 12 parts of sebacic acid into the reaction kettle, raise the temperature to 188°C-190°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com