Production and preparation method of lightweight aggregate

A lightweight aggregate and preparation step technology, applied in the field of lightweight aggregate production and preparation, can solve the problems affecting the screening effect of shale rock raw materials, affecting the crushing efficiency of shale rock, and easy to pile up for screening, etc., to achieve It is convenient for crushing treatment, improves screening efficiency and screening effect, and improves the effect of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific drawings. It should be noted that, in the case of no conflict, the embodiments and Features in the embodiments can be combined with each other.

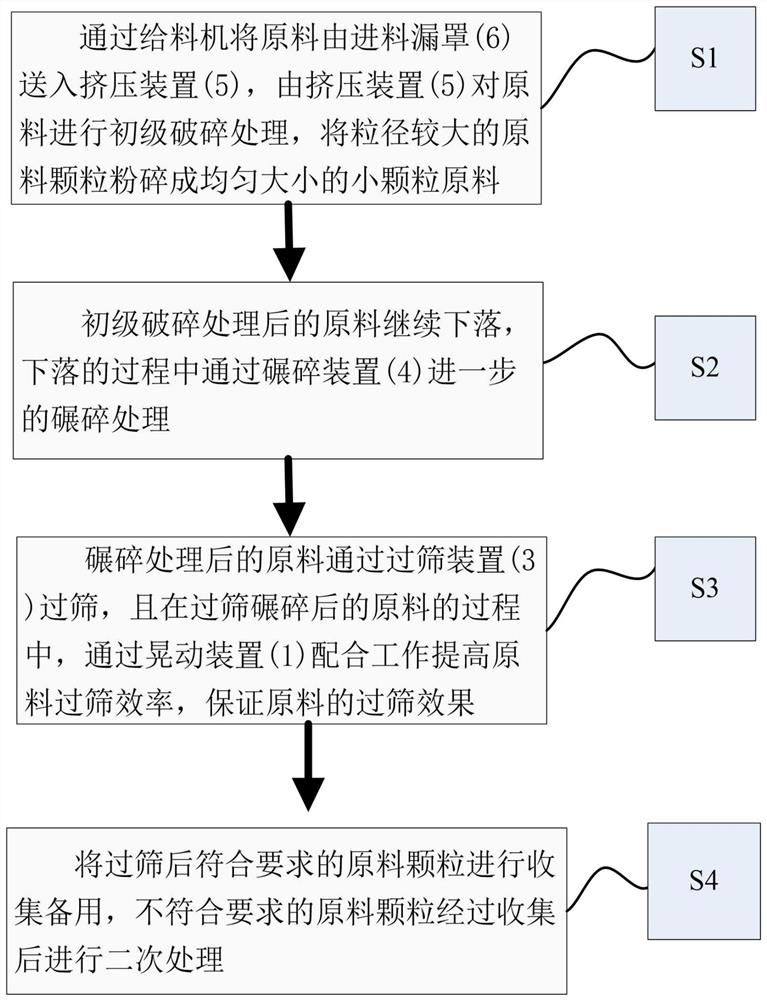

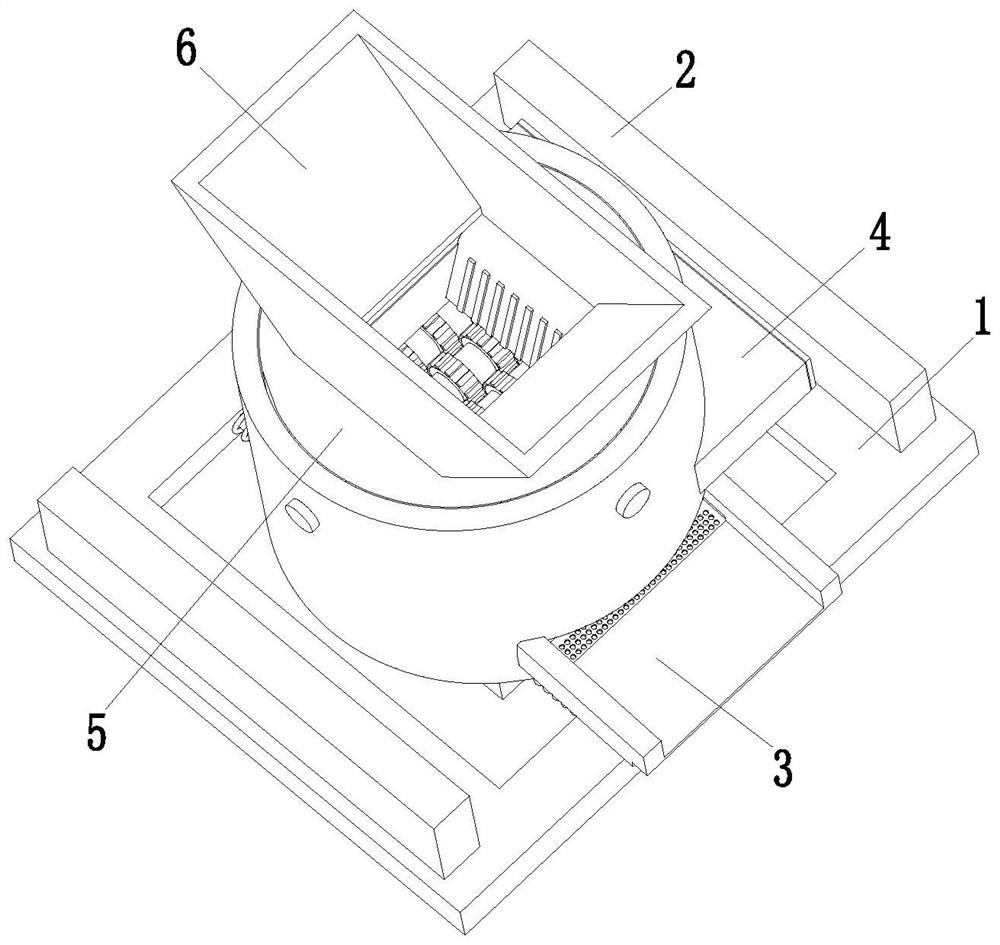

[0036] refer to figure 1 , figure 2 and image 3 , a production and preparation method of lightweight aggregates, the production and preparation steps of specific lightweight aggregates are as follows: S1, preliminary crushing: the raw materials are sent to the extrusion device 5 from the feeding leakage cover 6 through the feeder, and the extrusion The device 5 performs primary crushing treatment on the raw material, and crushes the raw material particles with larger particle size into small particle raw materials with uniform size.

[0037] S2. Crushing treatment: the primary crushed raw materials continue to fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com