Multifunctional mesoporous biological material, preparation method and application

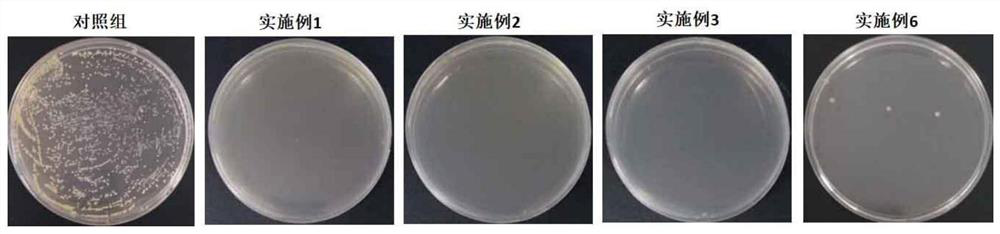

A biomaterial, multi-functional technology, applied in the field of soft/hard tissue wound regeneration and repair, body surface, and emergency biomaterials in the body, it can solve the problems of adverse effects on patients' physiological functions, asynchronous evolution of inflammatory responses, and inability to effectively eradicate infections. Achieve the effect of inhibiting the activity of common pathogens on the wound, good histocompatibility, and promoting the apoptosis of pathogens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

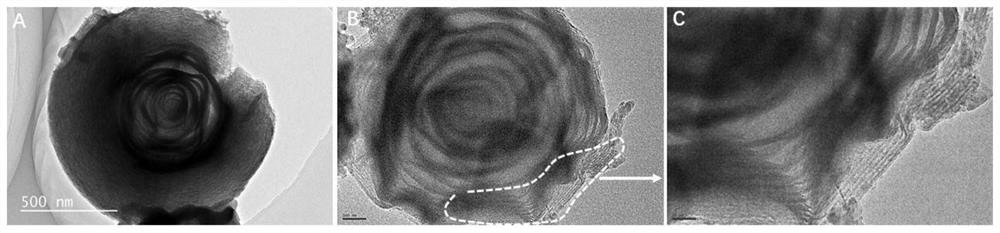

[0084] Example 1: SiO 2 -B 2 o 3 -CaO-P 2 o 5 -CuO-MgO-ZnO-SrO-Li 2 O-Na 2 O-K 2 O mesoporous material

[0085] 1) Add 0.02mol of P123 microstructure directing agent into 3000ml of deionized water at a ratio of 1:20, mechanically stir at 40°C for 4 hours to fully dissolve, adjust the pH value to 1.0 with hydrochloric acid solution, and continue stirring until the solution is clear ; Add 0.75mol tetraethyl orthosilicate to the above-mentioned acidic solution and fully hydrolyze it, add 0.06mol triethyl phosphate and hydrolyze it, followed by 0.57mol boric acid, 0.74mol calcium nitrate, 0.03mol copper nitrate, 0.01mol magnesium nitrate, 0.01 mol of zinc nitrate, 0.05mol of strontium nitrate, 0.01mol of lithium nitrate, 0.01mol of sodium nitrate, and 0.01mol of potassium nitrate were stirred at 40°C for 12 hours and at 95°C for 24 hours to obtain a sol solution;

[0086] 2) drying the sol solution obtained in step 1) at 120° C., and after fully drying, calcining at 700° C...

Embodiment 2

[0090] Example 2: SiO 2 -B 2 o 3 -CaO-P 2 o 5 -CuO-MgO-ZnO mesoporous materials

[0091] 1) Add 0.02mol of P123 microstructure directing agent into 3000ml of deionized water at a ratio of 1:30, mechanically stir at 40°C for 4 hours to fully dissolve, adjust the pH value to 2.0 with hydrochloric acid solution, and continue stirring until the solution is clear ; Add 0.89mol tetraethyl orthosilicate to the above-mentioned acidic solution and fully hydrolyze it, then add 0.04mol triethyl phosphate for hydrolysis, and successively add 0.23mol boric acid, 0.74mol calcium nitrate, 0.03mol copper nitrate, 0.01mol magnesium nitrate , 0.01mol zinc nitrate, stirred at 40°C for 12 hours, and stirred at 90°C for 24 hours to obtain a sol solution;

[0092] 2) Dry the sol solution obtained in step 1) at 120° C., and after fully drying, calcining at 650° C. for 6 hours to obtain a glassy mesoporous powder;

[0093] 3) Ball mill the powder obtained in step 2) for 5 hours, then add the ul...

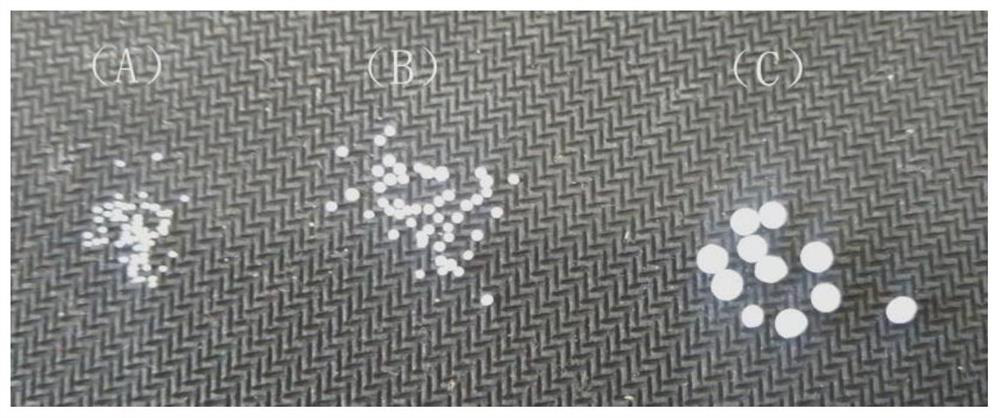

Embodiment 3

[0096] Example 3: SiO 2 -B 2 o 3 -CaO-P 2 o 5 -CuO-ZnO mesoporous material

[0097] 1) Add 0.02mol of F127 microstructure directing agent into 2500ml of deionized water at a ratio of 1:25, mechanically stir at 40°C for 4 hours to fully dissolve, adjust the pH value to 1.5 with nitric acid solution, and continue stirring until the solution is clear ; Then add 0.89mol tetraethyl orthosilicate and 0.02mol triethyl phosphate to the above-mentioned acidic solution and fully hydrolyze, then add 0.19mol boric acid, 0.52mol calcium nitrate, 0.005mol copper nitrate, 0.02mol zinc nitrate, at 40 ℃ Stir for 12 hours, then stir at 90°C for 24 hours to obtain a sol solution;

[0098] 2) Dry the sol solution obtained in step 1) at 120°C, and after fully drying, calcining at 700°C for 8 hours to obtain a glassy mesoporous powder;

[0099] 3) Mill the powder obtained in step 2) for 3 hours, then add the ultrafine powder into 15% calcium chloride solution at a solid-to-liquid ratio of 1:2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com