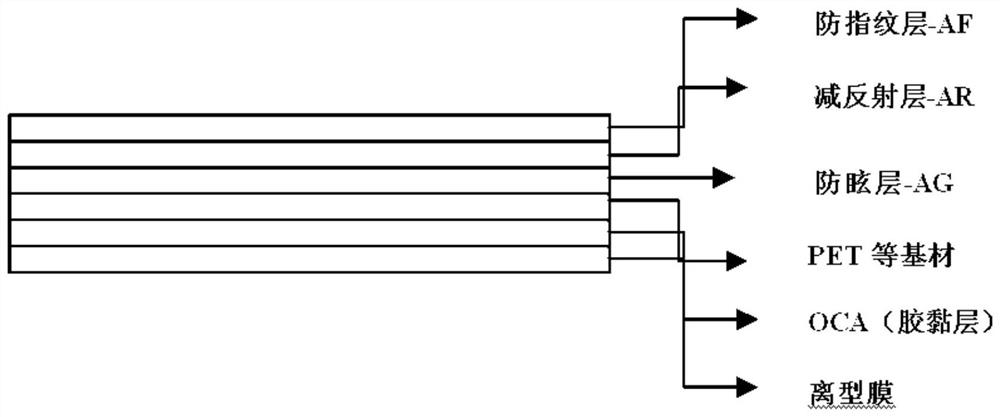

Diaphragm with integrated black display effect

A black display and integrated technology, applied in the field of display screens, can solve problems such as poor visual effects, achieve high production yield, improve picture quality, and reduce glass loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: To 25 parts by weight of urethane acrylate resin, add 15 parts by weight of hydrogen furfuryl acrylate, 18 parts by weight of propylene glycol methyl ether, 30 parts by weight of ethyl acetate, and 0.5 parts by weight of modified polydimethyloxane solution. Parts by weight, 1.5 parts by weight of modified organosiloxane polymer, 4 parts by weight of SIO2 particles, 0.5% of 50nm carbon black, after stirring evenly, add 6 parts by weight of lencolo5006 general-purpose photoinitiator 184, stir evenly, and obtain a coating liquid.

[0036] Coating the prepared coating solution on one side of the cellulose triacetate TAC substrate with a thickness of 60um, the coating thickness is 3-5um, the baking temperature is 80°C / 2min, and the UV curing condition is 500-700mj / cm2 UV radiation dose, test The properties of the relevant coating fluids are shown in Table 1.

Embodiment 2

[0037] Embodiment two: in the special modified pure acrylate resin of 30 weight parts, add 15 weight parts of hexanediol diacrylate, 15 weight parts of ethyl acetate, 25 weight parts of toluene, modified polydimethyloxane 0.8 parts by weight of solution, 1.2 parts by weight of modified organosiloxane polymer, 4 parts by weight of PMMA particles, 1.5% of 70nm carbon black, after stirring evenly, add 9 parts by weight of lencolo 5022 754 photoinitiator, stir evenly, and obtain the coating cloth liquid.

[0038] Coating the prepared coating liquid on one side of the cellulose triacetate TAC substrate with a thickness of 60um, the coating thickness is 4-6um, the baking temperature is 80°C / 1.5min, and the UV curing condition is 400-600mj / cm2 UV irradiation dose, The performance of the relevant coating liquids was tested, and the results are shown in Table 1.

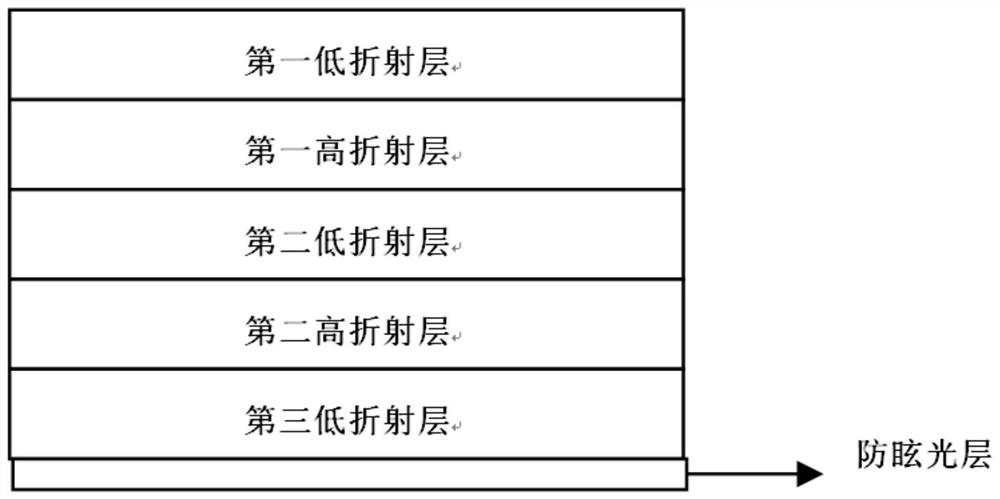

[0039] Such as figure 2 , the outermost layer of the anti-reflection absorbing layer is a low-refractive-index film laye...

Embodiment 3

[0041] Embodiment three: the thickness of the first low refractive index SIO2 film layer is 75~95nm, the thickness of the first high refractive index Nb2O5 film layer is 95~115nm, the thickness of the second low refractive index SIO2 film layer is 30~45nm, the second The thickness of the second high refractive index Nb2O5 film layer is 7-15nm, the thickness of the third low refractive index SIO2 film layer is 30-45nm, and the reflectivity is <0.6%. The test results are shown in Table 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com