Construction method of curved surface honeycomb array and application of curved surface honeycomb array

An array structure and honeycomb structure technology, applied in the field of nanocomposite materials, can solve the problems of lack of manufacturable structure change space, insufficient application field, harsh test conditions, etc. Repeatable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

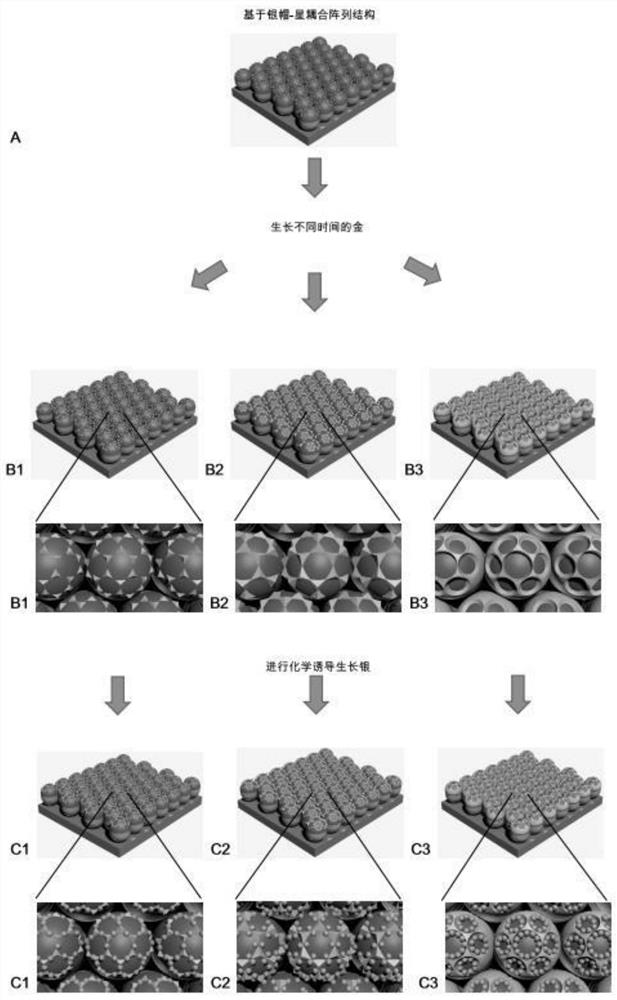

[0050] according to figure 1 The flow chart for preparing the curved honeycomb array precursor is shown:

[0051] (A) On the basis of multilayer nanocap-star coupled periodic array, sputtering Pt to form Pt nanocap-star coupled periodic array structure;

[0052] (B) sputtering a layer of Au with a thickness of 30nm on the basis of the nanocap-star coupled periodic array structure in step (A), to obtain a curved surface honeycomb array precursor (such as figure 1 shown in B1), including Pt-SiO 2 The double-layer substrate and the nano-Au honeycomb array precursor grown on its surface; the SEM image of the structural precursor of the honeycomb structure variant can be found in Figure 8 .

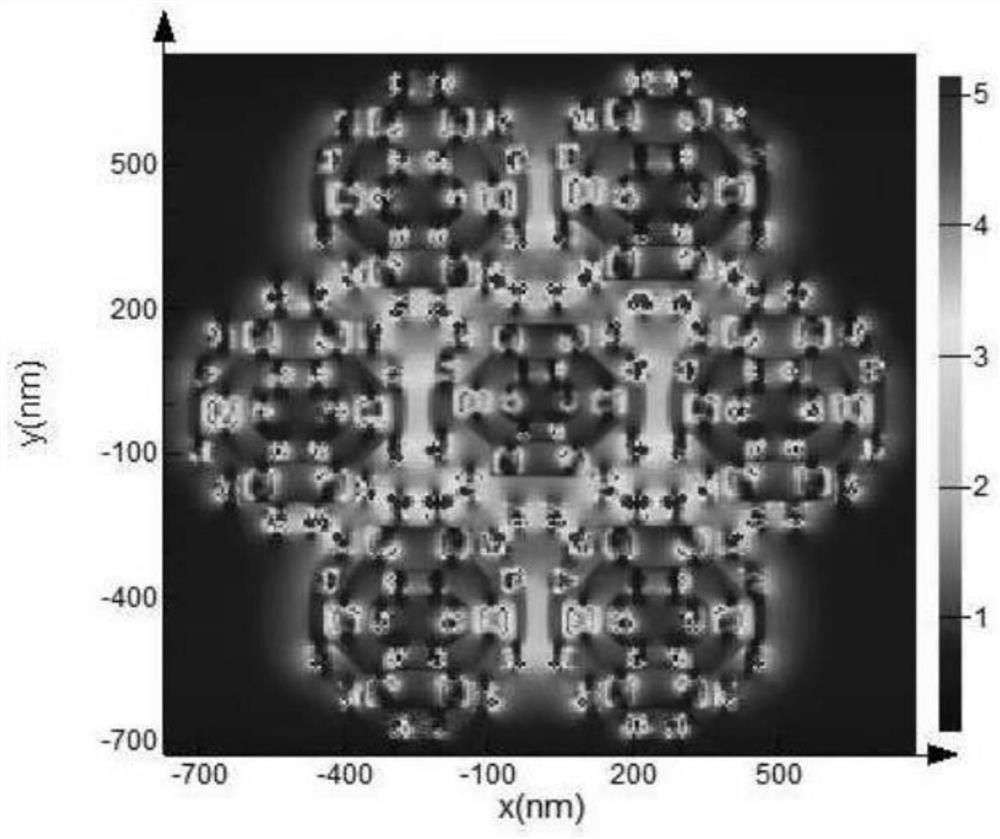

[0053] figure 2 It is the FDTD structure simulation diagram of the curved surface honeycomb array precursor prepared in this embodiment. It can be seen from the figure that the triangular pyramid array attached with nano-gold is attached to the surface of the sphere in the shape of a he...

Embodiment 2

[0056] according to figure 1 The flow chart shown in the preparation of curved surface honeycomb array structure 1:

[0057] (A) On the basis of the multilayer nanocap-star coupled periodic array, Ag sputtered to form the Ag nanocap-star coupled periodic array structure;

[0058] (B) sputtering a layer of Pt with a thickness of 80nm on the basis of the nanocap-star coupling periodic array structure in step (A), to obtain a curved surface honeycomb array structure one (such as figure 1 B2), including Ag-SiO 2 Double-layer substrate and nano-Pt honeycomb array structure grown on its surface; the SEM image of the precursor of the honeycomb structure can be found in Figure 9 .

[0059] Figure 4 It is the FDTD structure simulation diagram of the curved surface honeycomb array structure 1 prepared in this embodiment. It can be seen from the figure that the porous array is attached to the surface of the sphere in a honeycomb shape, and the appropriate height difference between...

Embodiment 3

[0062] according to figure 1 The flow chart shown in the preparation of curved surface honeycomb array structure II:

[0063] (A) On the basis of multilayer nanocap-star coupled periodic array, sputtering Pt to form Pt nanocap-star coupled periodic array structure;

[0064](B) sputtering a layer of Au with a thickness of 120nm on the basis of the nanocap-star coupled periodic array structure in step (A), to obtain a curved surface honeycomb array structure 2 (such as figure 1 B3), including Pt-SiO 2 The double-layer substrate and the nano-Au honeycomb array structure grown on its surface II; the SEM picture of the structural precursor of the honeycomb structure can be found in Figure 9 .

[0065] Figure 6 It is the FDTD structure simulation diagram of the curved honeycomb array structure 2 prepared in this embodiment. It can be seen from the figure that the porous array is attached to the surface of the sphere in a honeycomb shape, and the appropriate height difference b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com