Manufacturing method of flocking hot-rolling coating pattern-blowing plate for marine engineering

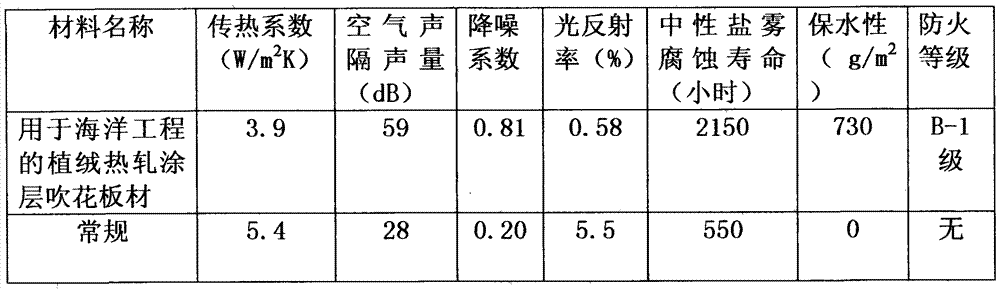

A technology of marine engineering and manufacturing method, which is applied in the field of manufacturing flocking hot-rolled coated blown flower boards, can solve the problem of corrosion resistance, erosion resistance, humidity and heat resistance that cannot adapt to harsh marine climate environment, flocking heat The rolled steel plate cannot achieve the light diffuse reflection effect, and the flocking hot-rolled steel plate does not have a strong velvet feeling, etc., to achieve the effect of ensuring the bonding strength and oxidation resistance, excellent light diffuse reflection effect, and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present invention is used for the manufacture method of the flocking hot-rolled coating blown flower plate of offshore engineering comprising the following steps:

[0027] (1), material selection; the material selection is a hot-rolled steel plate with a thickness of 0.12mm and a width of 3500mm;

[0028] (2) Plate surface pretreatment: After uncoiling, deflection correction, and material storage, the hot-rolled steel plate with a clean surface and an unoiled thickness of 0.12mm and a width of 3500mm is sent to the surface coating machine for further processing. The board surface pretreatment of coating the board surface treatment agent, the coated board surface treatment agent is GR934 passivation agent produced by Nippon Paint, the single-side coating speed of the board surface treatment agent is: 20m / min, the board surface treatment agent The amount of coating on one side is: 2.5g / m 2 , the temperature of the surface treatment agent is 18°C when coating;

[0...

Embodiment 2

[0047] The present invention is used for the manufacture method of the flocking hot-rolled coating blown flower plate of offshore engineering comprising the following steps:

[0048] (1) Material selection: The material selection is a hot-rolled steel plate with a thickness of 2.5mm and a width of 500mm;

[0049] (2) Plate surface pretreatment: After uncoiling, deflection correction, and material storage, the hot-rolled steel plate with a clean surface and an unoiled thickness of 2.5mm and a width of 500mm is sent to the surface coating machine for further processing. The board surface pretreatment of coating the board surface treatment agent, the coated board surface treatment agent is GR934 passivation agent produced by Nippon Paint, the single-side coating speed of the board surface treatment agent is: 35m / min, the board surface treatment agent The amount of coating on one side is: 1.5g / m 2 , the temperature of the surface treatment agent is 28°C when coating;

[0050] (3...

Embodiment 3

[0066] The present invention is used for the manufacture method of the flocking hot-rolled coating blown flower plate of offshore engineering comprising the following steps:

[0067] (1) Material selection: the material selection is a hot-rolled steel plate with a thickness of 1.2mm and a width of 2500mm;

[0068] (2) Plate surface pretreatment: After uncoiling, deflection correction, and material storage, the hot-rolled steel plate with a thickness of 1.2mm and a width of 2500mm that has a clean surface and has not been oiled is sent to the surface coating machine for further processing. The board surface pretreatment of coating the board surface treatment agent, the coated board surface treatment agent is GR934 passivation agent produced by Nippon Paint, the single-side coating speed of the board surface treatment agent is: 25m / min, the board surface treatment agent The amount of coating on one side is: 2.1g / m 2 , the temperature of the surface treatment agent is 25°C when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com