Heat dissipation device provided with heat dissipation fan and used for electrical device

A heat dissipation device and heat dissipation fan technology, which is applied to the structural parts of electrical equipment, electrical components, and decoration through conduction and heat transfer, can solve the problems of slow heat transfer, uneven heat transfer, low heat dissipation efficiency, etc., and achieve structural stability. Strong adaptability, reduce heat accumulation, improve heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

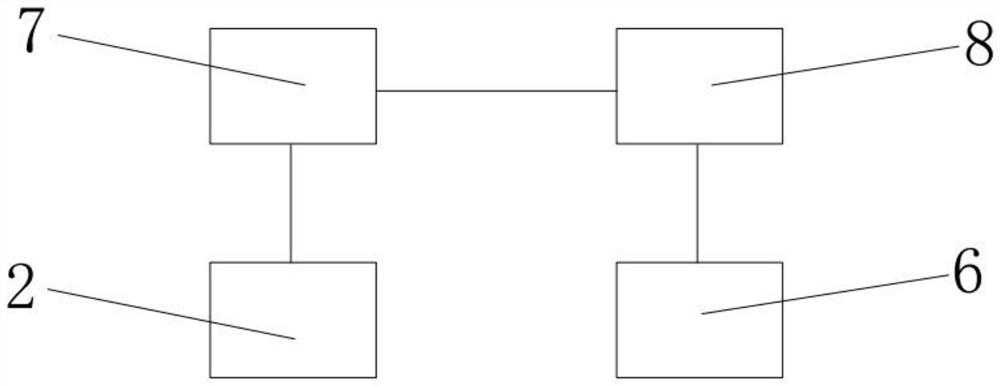

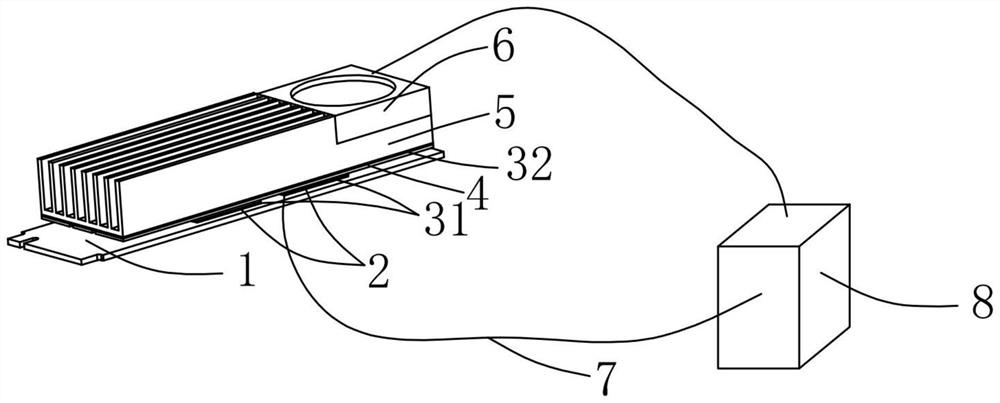

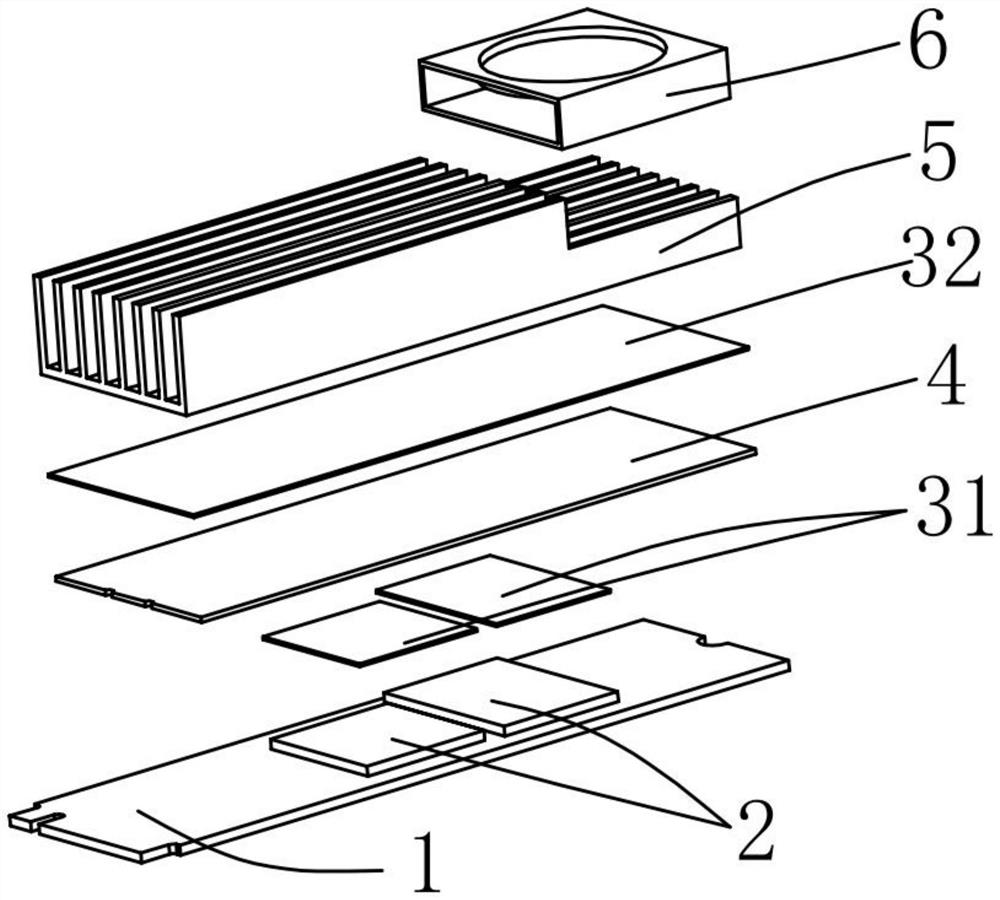

[0031] Such as Figure 1-3 As shown, the heat dissipation device for electrical equipment provided with a heat dissipation fan includes a body 1 and a chip 2 arranged above the body 1. On the other side of the chip 2 relative to the body 1, a first heat-conducting silicone gasket 31, a heat dissipation The element 4, the second heat-conducting silicone gasket 32, the heat dissipation module 5 and the heat dissipation fan 6; wherein the heat dissipation element 4 is a heat pipe or a vapor chamber, and the heat dissipation fan 6 is a variable-speed fan.

[0032] In this embodiment 1, the heat dissipation module 5 is an aluminum extrusion, and the heat dissipation fan 6 is fixed on the aluminum extrusion. Specifically, the heat dissipation fan 6 can be fixed on the upper surface of the heat dissipation module 5 through heat-conducting silica gel or screws.

[0033] The chip 2 has a cuboid sheet structure, the pins of the chip 2 are welded on the body 1, the size of the first the...

Embodiment 2

[0038] In this embodiment 2, the heat dissipation principle of the heat dissipation device for electrical equipment provided with a heat dissipation fan is the same as that of embodiment 1, as figure 1 Shown; The structure of heat sink is basically the same as embodiment 1, as Figure 4 and 5 Shown, in this embodiment 2:

[0039] The heat dissipation device for electrical equipment provided with a heat dissipation fan includes a body 1 and a chip 2 arranged above the body 1. On the other side of the chip 2 relative to the body 1, a thermally conductive silicone gasket 3, a heat dissipation module 5 and a heat dissipation module are sequentially provided. A fan 6; wherein the cooling element 4 is a heat pipe or a vapor chamber, and the cooling fan 6 is a variable-speed fan.

[0040] In this embodiment 2, the heat dissipation module 5 is an aluminum extrusion, and the heat dissipation fan 6 is fixed on the aluminum extrusion. Specifically, the heat dissipation fan 6 can be fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com