Emergency braking mechanism applied to adjusting shaft

A technology for emergency braking and adjusting the shaft, applied in the field of adjusting the shaft, can solve the problems of affecting work efficiency, simple structure, lack of functions, etc., and achieve the effect of increasing the ground area, prolonging the service life, and strong functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

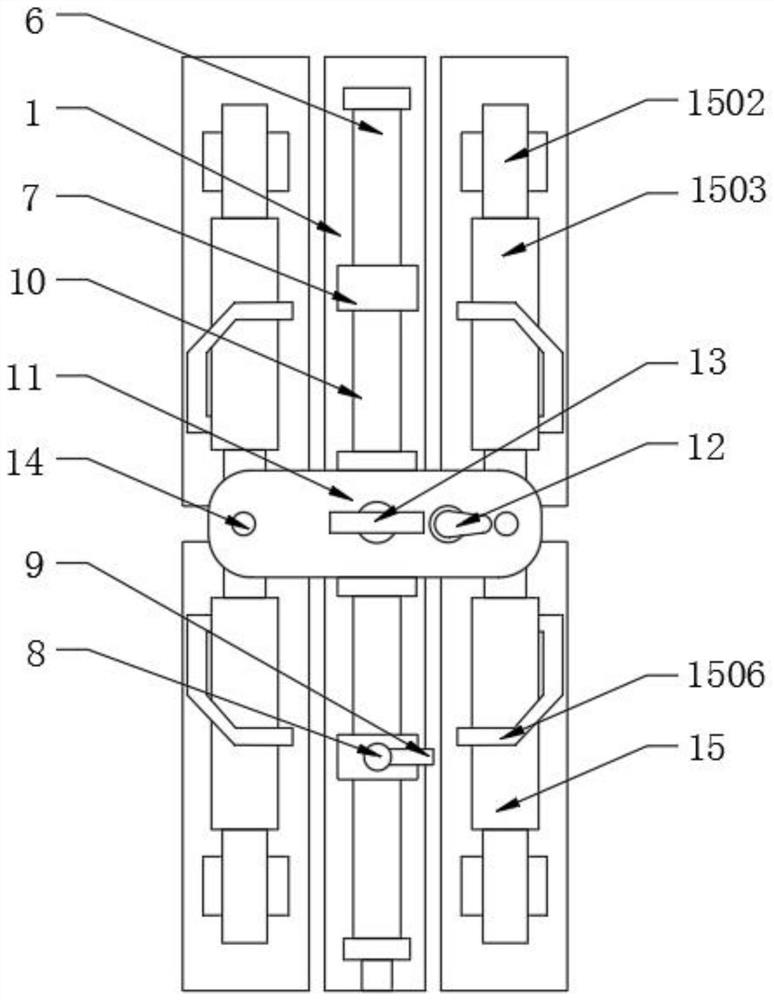

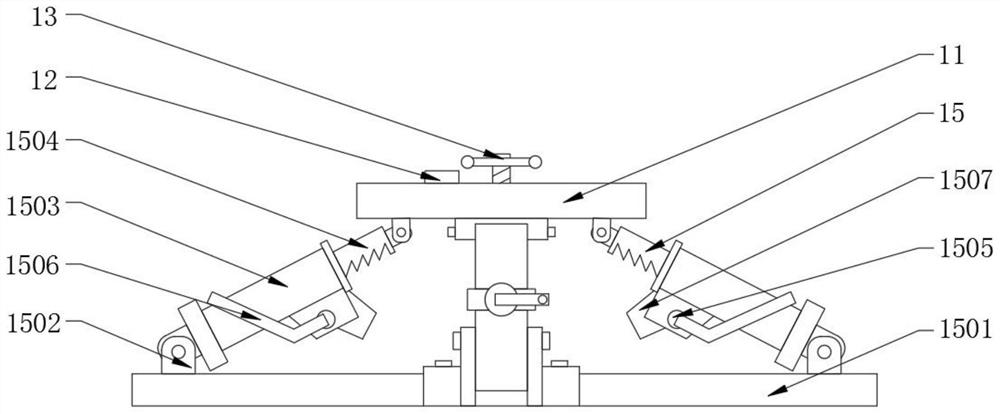

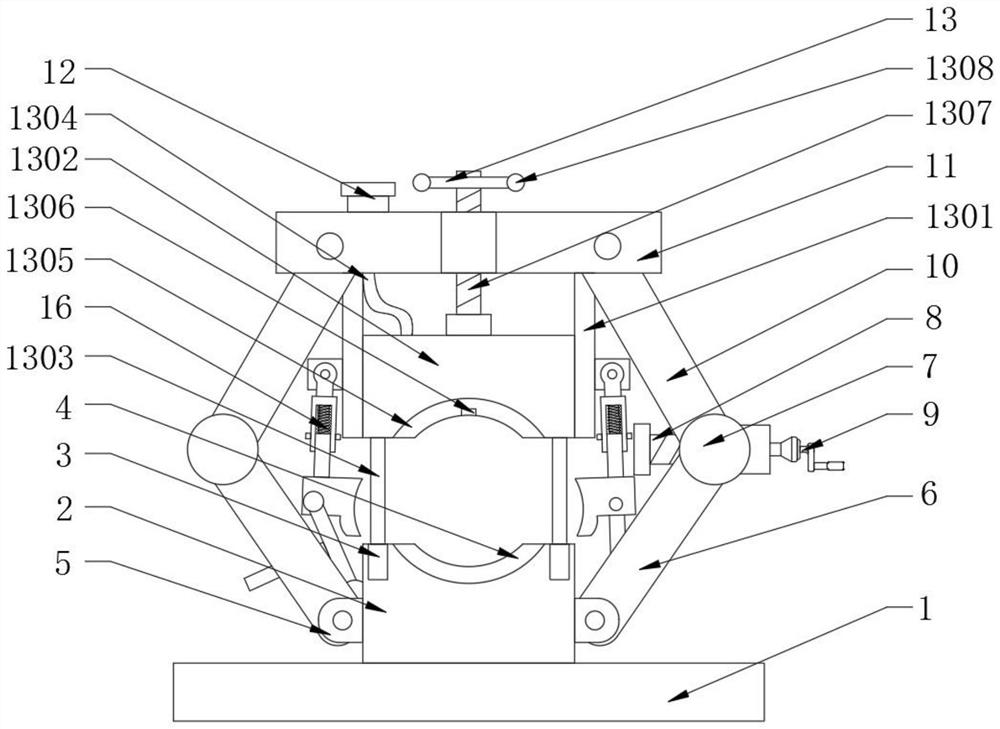

[0027] see figure 1 , the present invention provides a technical solution: an emergency braking mechanism applied to an adjustment shaft, a bottom platform 2 is fixedly installed in the middle of the middle rail 1, and guide grooves 3 are symmetrically opened on both sides of the bottom platform 2, and the top of the bottom platform 2 is provided with a guide groove 3. The end face is provided with a bottom groove 4 with a cross-section of a semi-circular arc, and a connecting pin 5 is symmetrically and fixedly installed on both sides of the outside of the bottom platform 2, and the outer side of the connecting pin 5 is rotatably connected with a bottom support rod 6, and the top end face of the bottom support rod 6 is provided with a toggle joint. 7, and the inside of the toggle 7 is laterally engaged and installed with a lead screw 8, the right input end of the lead screw 8 is fitted with a rocker 9, the top of the bottom strut 6 is provided with a top strut 10, and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com