Real-time monitoring system for workshop enamelling machine

A real-time monitoring and enamelling machine technology, applied in general control system, control/adjustment system, program control, etc., can solve problems such as damage to workers' health, paint volatilization, and complicated electrical facilities, so as to improve real-time control and reduce Labor cost, the effect of shortening the R&D cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

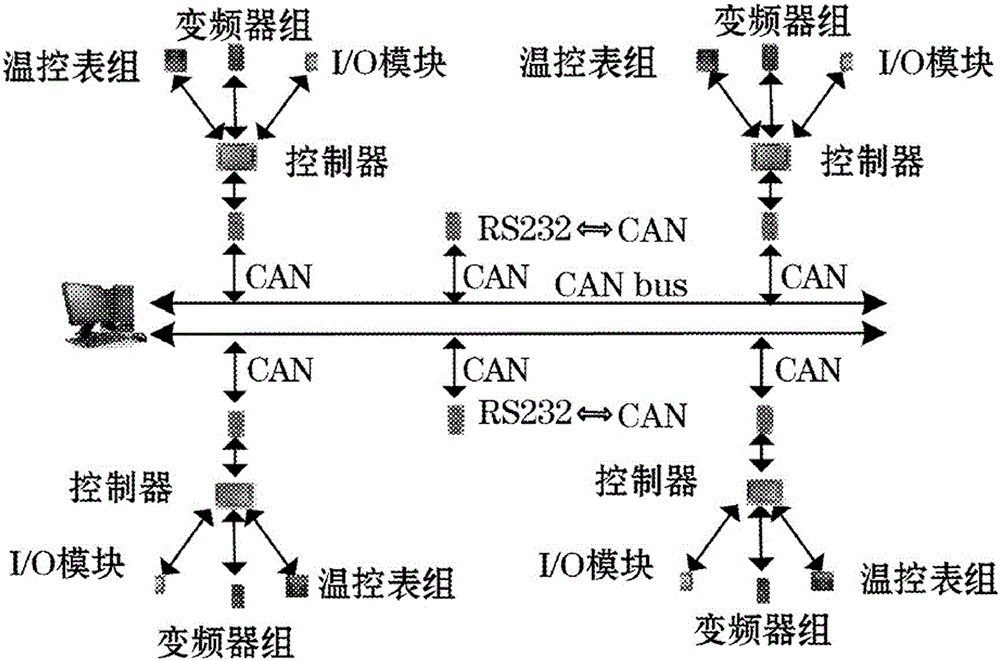

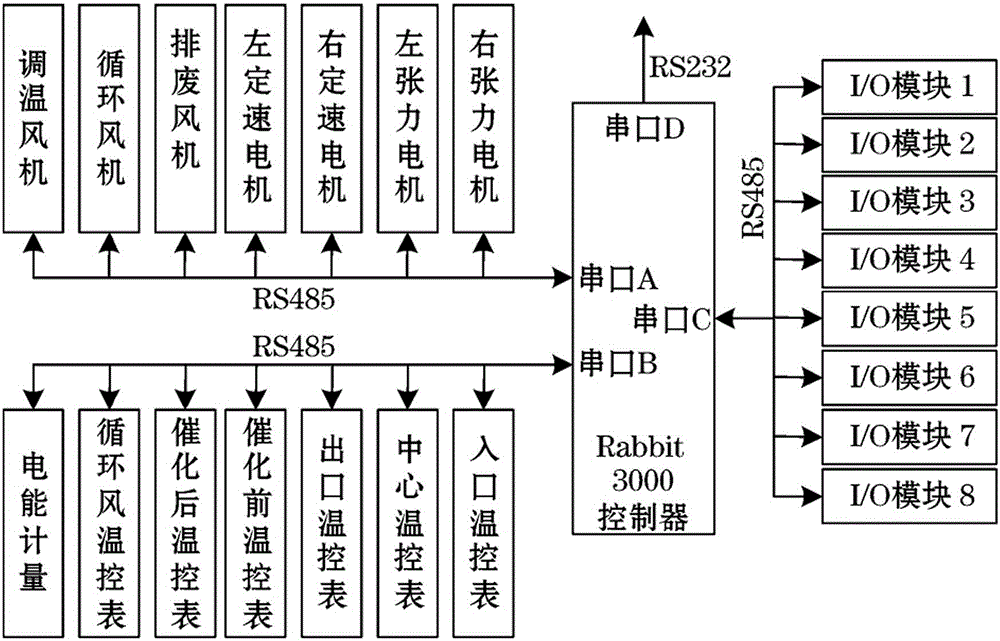

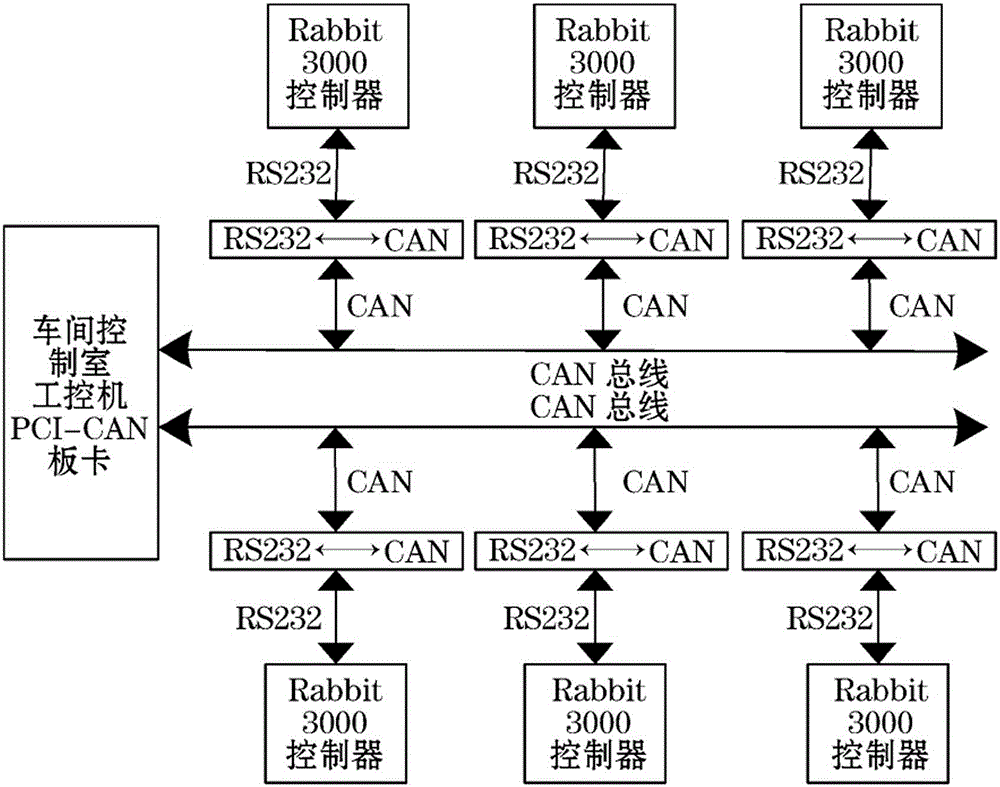

[0018] combined with figure 1 , 2 Shown in and 3, a kind of workshop enamelling machine real-time monitoring system of the present invention comprises and comprises single enamelling machine control module, workshop enamelling machine network module and control room real-time monitoring module, adopts CAN bus communication mode; Its structural points are: all The single enamelling machine control module includes a temperature control meter group, a frequency converter group, an I / O module, and a controller, and the temperature control meter group, frequency converter group, and I / O modules are all connected to the controller; the workshop The enamelling machine network module includes the PCI-CAN board of the industrial computer in the workshop control room, and the PCI-CAN board of the industrial computer in the workshop control room communicates with the controller through the CAN bus; the temperature control table group includes the circulating air temperature control tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com