Novel movable rubber jacketed flexible cable for coal mine frequency conversion device

A frequency conversion device and flexible cable technology, applied in the direction of insulated cables, flexible cables, power cables with shielding layer/conductive layer, etc., can solve the problem of outer semi-conductive layer wear, cable outer sheath damage, internal circuit exposure, etc. problem, to achieve high elongation at break, strengthen wear resistance, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

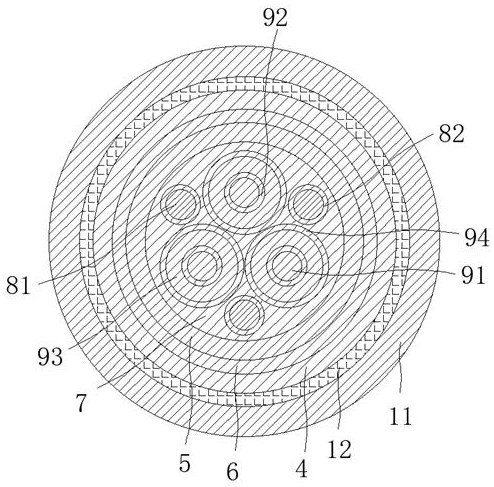

[0032] Further, such as image 3 As shown, the tensile outer sheath 1 includes a polyvinyl chloride layer 11 and a Kevlar fiber layer 12. Kevlar is a liquid crystalline rod-shaped molecule, which has very good thermal stability, fire resistance, and Chemical, insulating, and high strength and modulus, through 12 can improve the tensile resistance of the cable, because the Kevlar fiber layer 12 is a new type of aramid fiber composite material, and has good deformability, when used It has a high rupture elongation, and at the same time, the polyvinyl chloride layer 11 has a certain wear resistance, which further protects the circuit structure inside the tensile outer sheath 1 .

Embodiment 2

[0034] Further, such as image 3 As shown, a wrapping tape 6 is wound on the outer wall of the inner sheath 5, and concentric wrapping is adopted, and each wrapping head wraps one layer. The whole wrapping process can be divided into rotary motion and linear motion. The wrapping tape 6 reel rotates around the inner sheath 5 with the bagging machine head, and the wrapping tape 6 is wound on the outer wall of the inner sheath 5, and the inner sheath 5 is protected by the wrapping tape 6, Acts as padding and cushioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com