A kind of single/dual atom catalyst and its controllable synthesis method and application

A catalyst and diatomic technology, applied in the field of single/dualatom catalysts and their controllable synthesis, can solve problems such as the exploration of the universality of limiting elements, high overpotential, selective attenuation, etc., and achieve low preparation cost and stable catalytic performance. The effect of good performance and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Dry a certain amount of sodium citrate tetrahydrate in an oven at 150 degrees Celsius for 48 hours;

[0046] The dried sodium citrate was transferred to a tube furnace at 800 degrees Celsius and calcined under an argon atmosphere for 1 hour to obtain a black product; then the obtained black product was ground into black powder with a mortar;

[0047] The black powder was added to a sulfuric acid solution with a concentration of 3 mol / L, and heated at 80 degrees Celsius for 12 hours;

[0048] The sulfuric acid solution dispersed with the black powder is subjected to suction filtration, and then washed to neutrality with ultrapure water and ethanol to obtain the black powder after suction filtration;

[0049] The black powder after suction filtration was dried in an oven at 75 degrees Celsius for 12 hours to obtain porous carbon nanosheets.

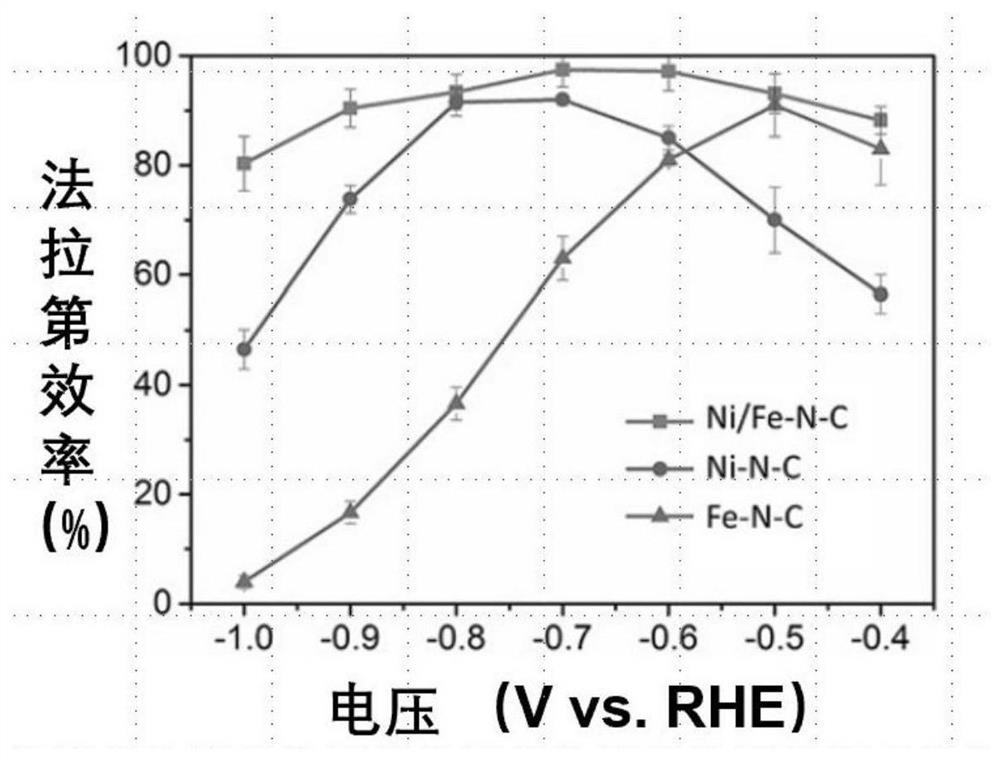

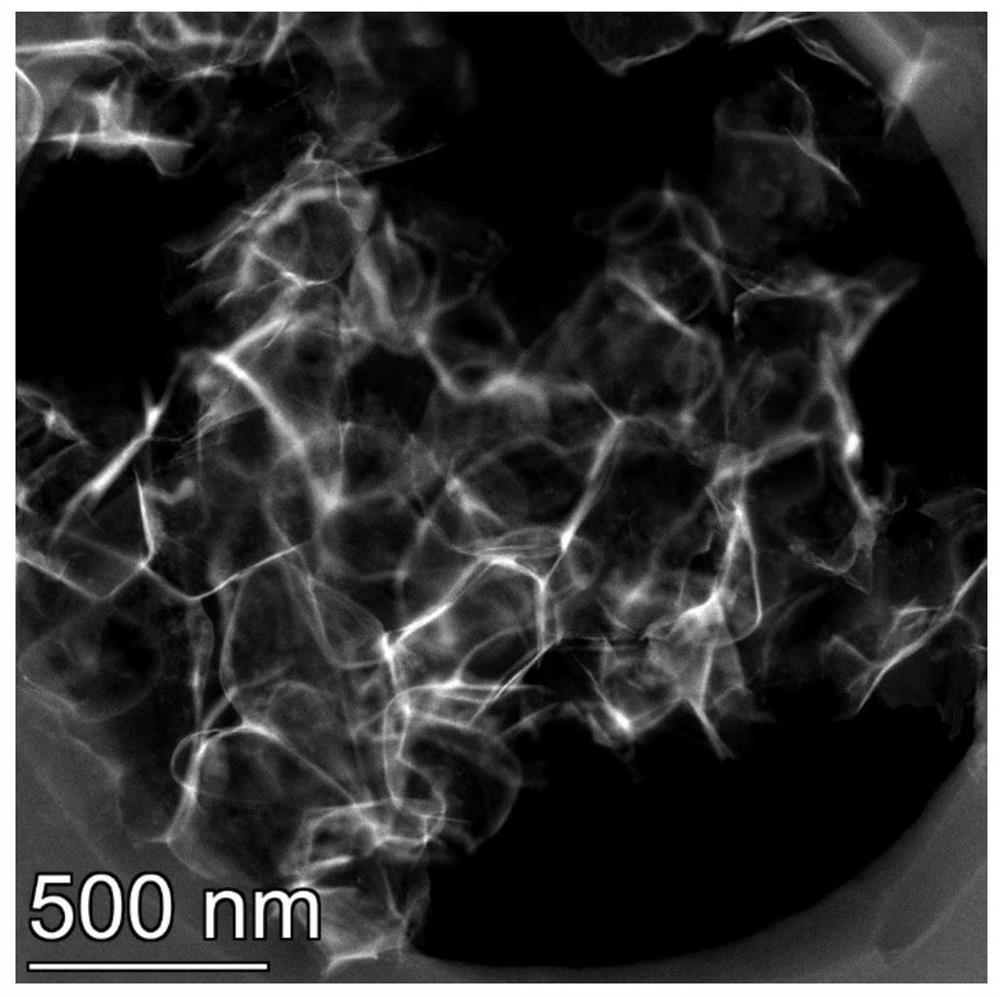

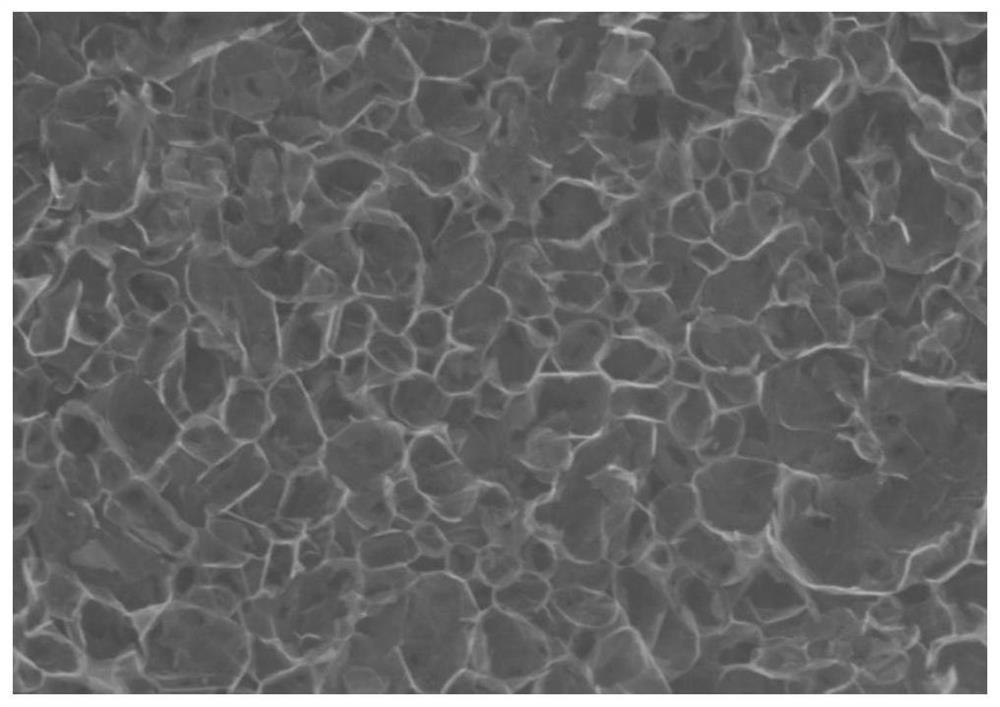

[0050] like figure 2 , image 3 shown, respectively, the spherical aberration corrected annular dark field phase scanning transmi...

Embodiment 2

[0052] Measure 2 ml of absolute ethanol and add it to a 10ml glass bottle, and perform magnetic stirring; take 12.8 mg of nickel acetate tetrahydrate and add it to the above glass bottle, continue stirring until it is completely dissolved; add 50 microliters of ammonia water to the glass bottle; Subsequently, 30 mg of citric acid was weighed and added to the above-mentioned glass bottle, and the stirring was continued for one hour; after the stirring was completed, 100 mg of the porous carbon nanosheets obtained in Example 1 were weighed and added to the above-mentioned glass bottle, and the stirring was continued for 12 hours; The uniform slurry obtained after stirring was placed in an oven at 75 degrees Celsius to dry for 12 hours to obtain a black solid; 1 gram of dicyandiamide was weighed and the black solid was ground, and then placed in a tube furnace at 800 degrees Celsius for calcination under an argon atmosphere. The sample was obtained in 2 hours; the calcined sample ...

Embodiment 3

[0054] Measure 2 ml of absolute ethanol and add it into a 10ml glass bottle, and perform magnetic stirring; take 12.8 mg of nickel acetate tetrahydrate and add it to the above glass bottle, and continue to stir until it is completely dissolved; then weigh 30 mg of citric acid and add it to the above-mentioned glass bottle. In the glass bottle, continue to stir for one hour; after stirring, weigh 100 mg of the porous carbon nanosheets prepared in Example 1 and add it to the above glass bottle, and continue stirring for 12 hours; place the uniform slurry obtained after stirring at 75 Dry in a degree Celsius oven for 12 hours to obtain a black solid; weigh 1 gram of dicyandiamide and grind the black solid, grind evenly and place it in a tube furnace at 800 degrees Celsius for calcination under an argon atmosphere for 2 hours to obtain a sample; the calcined sample is The hydrochloric acid solution with a concentration of 3 mol / L was washed for many times, and then washed with ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com