A kind of copper/graphene composite film material and its preparation method and application

A graphene composite, thin-film material technology, applied in heat exchange materials, chemical instruments and methods, metal material coating processes, etc., can solve the problems of poor thermal stability and low strength of pure copper, and achieve easy operation and preparation of equipment. Simple method, combined with good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

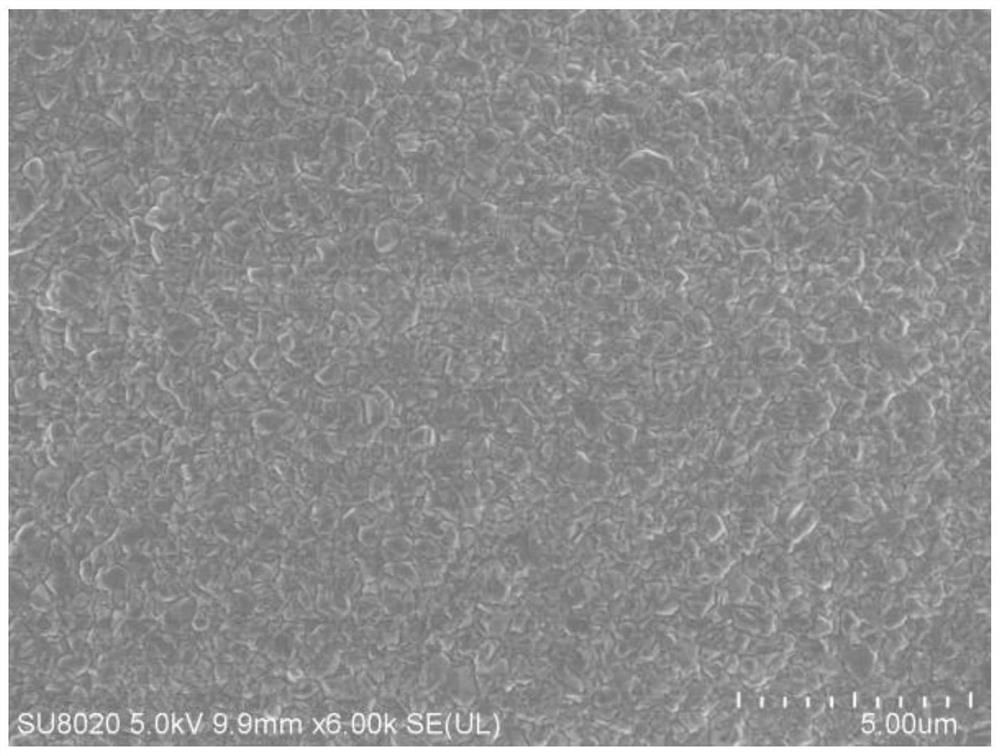

[0037] Embodiment 1 (comparative example, does not add graphene dispersion liquid)

[0038] Preparation of basic electroless copper plating thin film materials, the specific steps are as follows:

[0039] (1) Ultrasonic cleaning of the red copper sheet for 3 minutes, then soaking in 60°C alkaline washing solution for 4 minutes, taking it out and rinsing it with deionized water, putting it in 0.1mol / L dilute hydrochloric acid at room temperature for 30 seconds, and finally Rinse briefly with deionized water and blow dry;

[0040] (2) Preparation of alkaline lotion: Weigh 20g of trisodium phosphate, 20g of sodium carbonate and 8g of sodium hydroxide per liter of deionized water, place them in 100mL of deionized water, and stir at a constant temperature of 60°C until clear;

[0041] (3) Preparation of basic electroless copper plating solution: Weigh 10g of copper sulfate pentahydrate, 14g of potassium sodium tartrate, 20g of disodium edetate, 12g of sodium hydroxide, 20mg of 2,2...

Embodiment 2

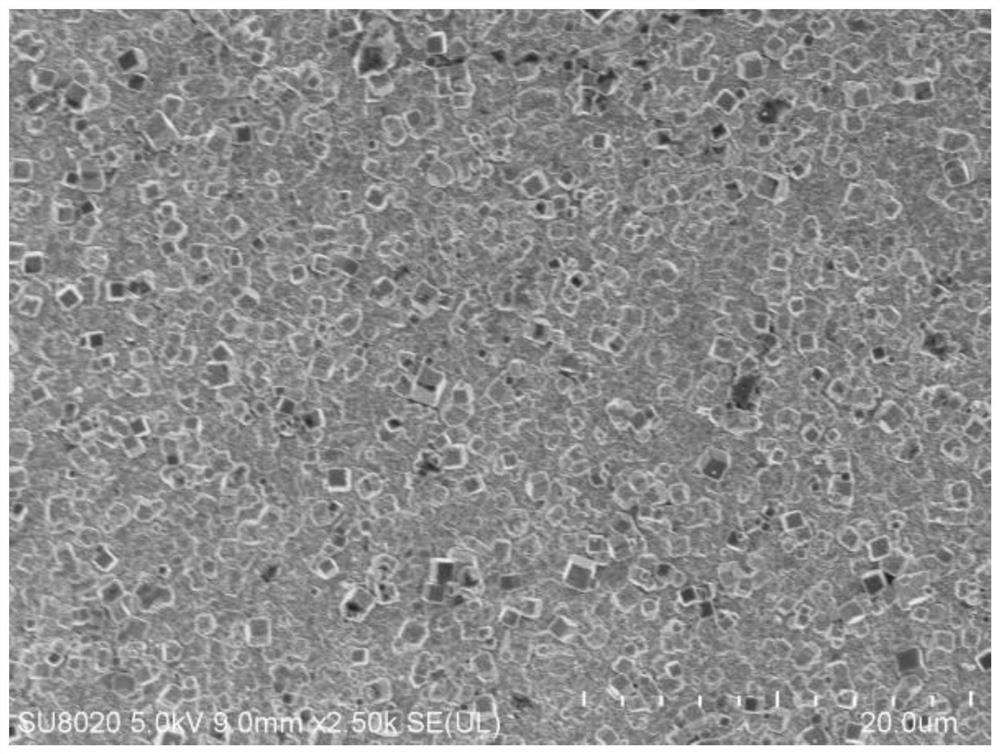

[0046] A kind of preparation method of copper / graphene composite film, concrete steps are as follows:

[0047] (1) Ultrasonic cleaning of the red copper sheet for 3 minutes, then soaking in 50°C alkaline washing solution for 4 minutes, taking it out and rinsing it with deionized water, putting it in 0.1mol / L dilute hydrochloric acid at room temperature for 30 seconds, and finally Rinse briefly with deionized water and blow dry;

[0048] (2) Preparation of alkaline lotion: Weigh 10g of trisodium phosphate, 10g of sodium carbonate and 8g of sodium hydroxide for each liter of deionized water, place them in 100mL of deionized water, and stir at a constant temperature of 50°C until clear;

[0049] (3) Prepare a 0.1g / L single-layer graphene dispersion: weigh 1 mg of single-layer graphene and dissolve it in 10 mL of deionized water. The agent is composed of polyvinylpyrrolidone and chloroform with a mass ratio of 2:1, ultrasonicated again and stirred for 2 hours before use, and stir...

Embodiment 3

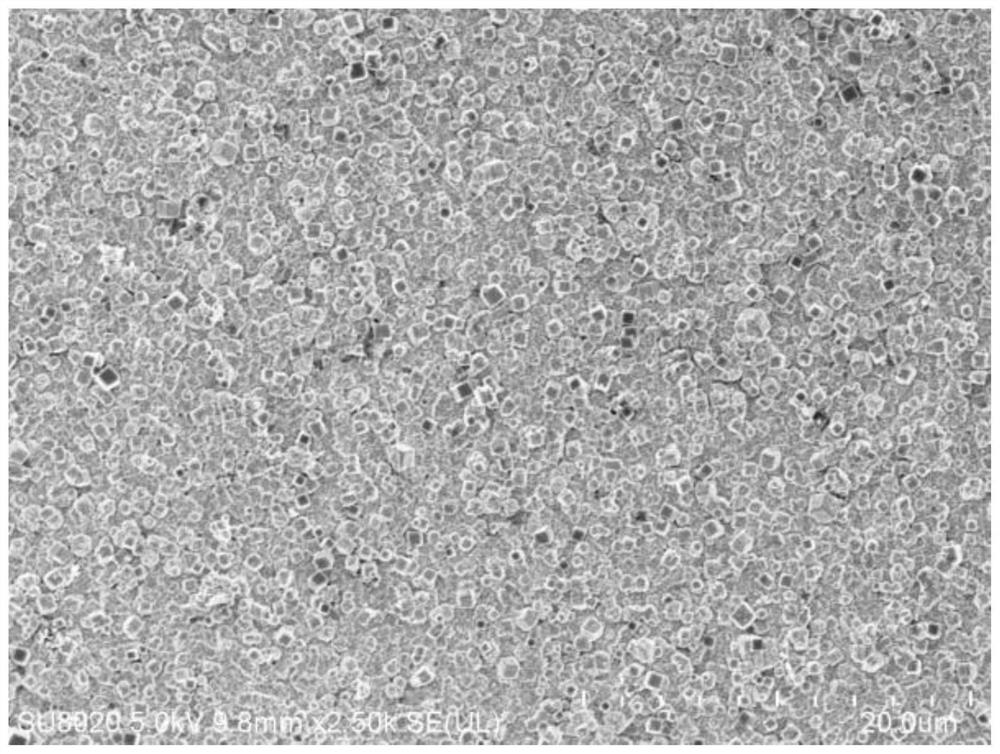

[0056] A kind of preparation method of copper / graphene composite film, concrete steps are as follows:

[0057] (1) Ultrasonic cleaning of the red copper sheet for 3 minutes, then soaking in 60°C alkaline washing solution for 4 minutes, taking it out and rinsing it with deionized water, putting it in 0.1mol / L dilute hydrochloric acid at room temperature for 30 seconds, and finally Rinse briefly with deionized water and blow dry;

[0058] (2) Preparation of alkaline lotion: Weigh 30g of trisodium phosphate, 30g of sodium carbonate and 5g of sodium hydroxide for each liter of deionized water, place them in 100mL of deionized water, and stir at a constant temperature of 60°C until clear;

[0059] (3) Prepare a 0.5g / L single-layer graphene dispersion: weigh 5 mg of single-layer graphene and dissolve it in 10 mL of deionized water, ultrasonically and stir for 2 hours, then weigh 25 mg of mixed dispersant and add, wherein, mixed and dispersed The agent is composed of polyvinylpyrrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com