Method for preparing anti-high temperature oxidation mixed coating by electrophoretic codeposition

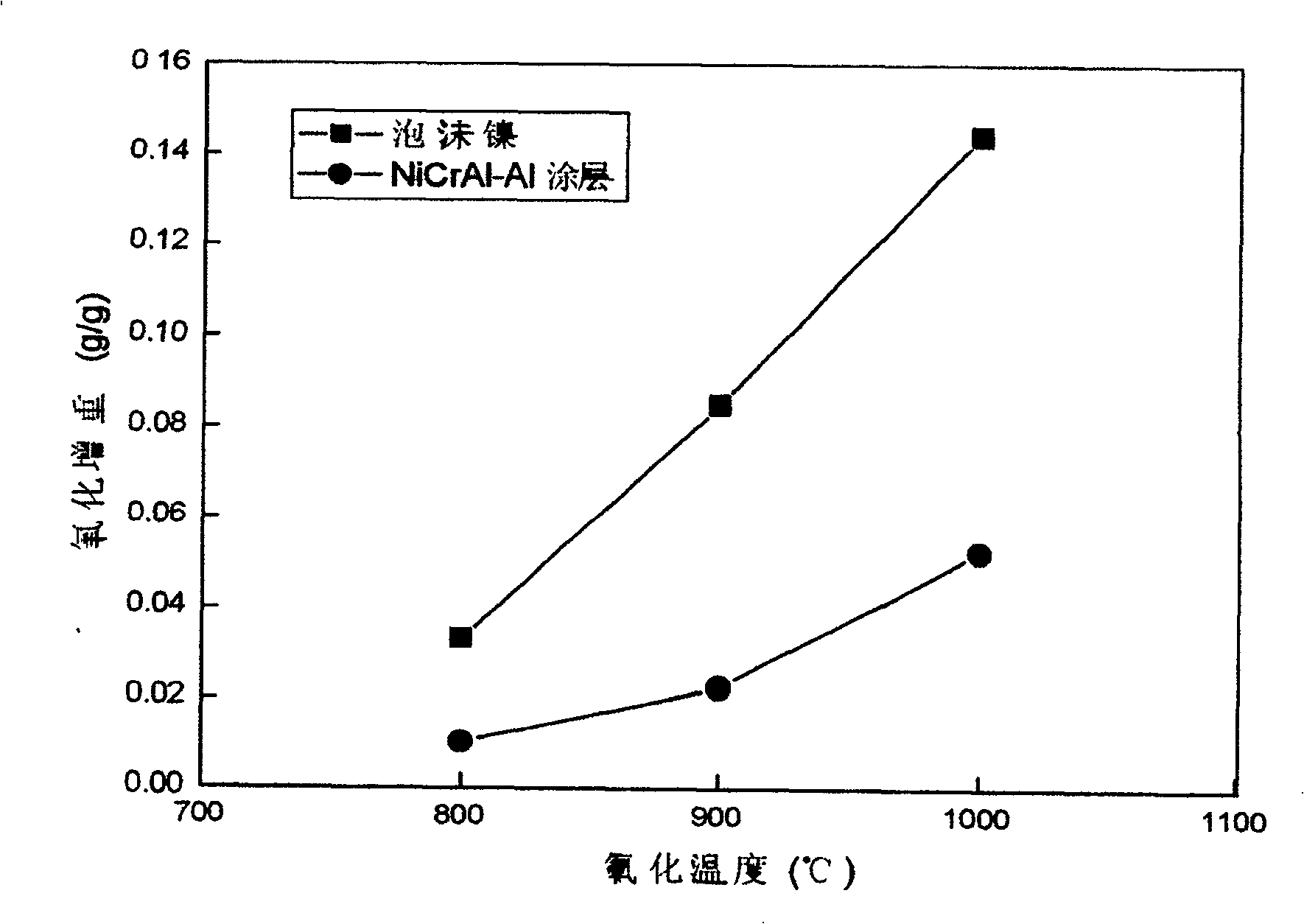

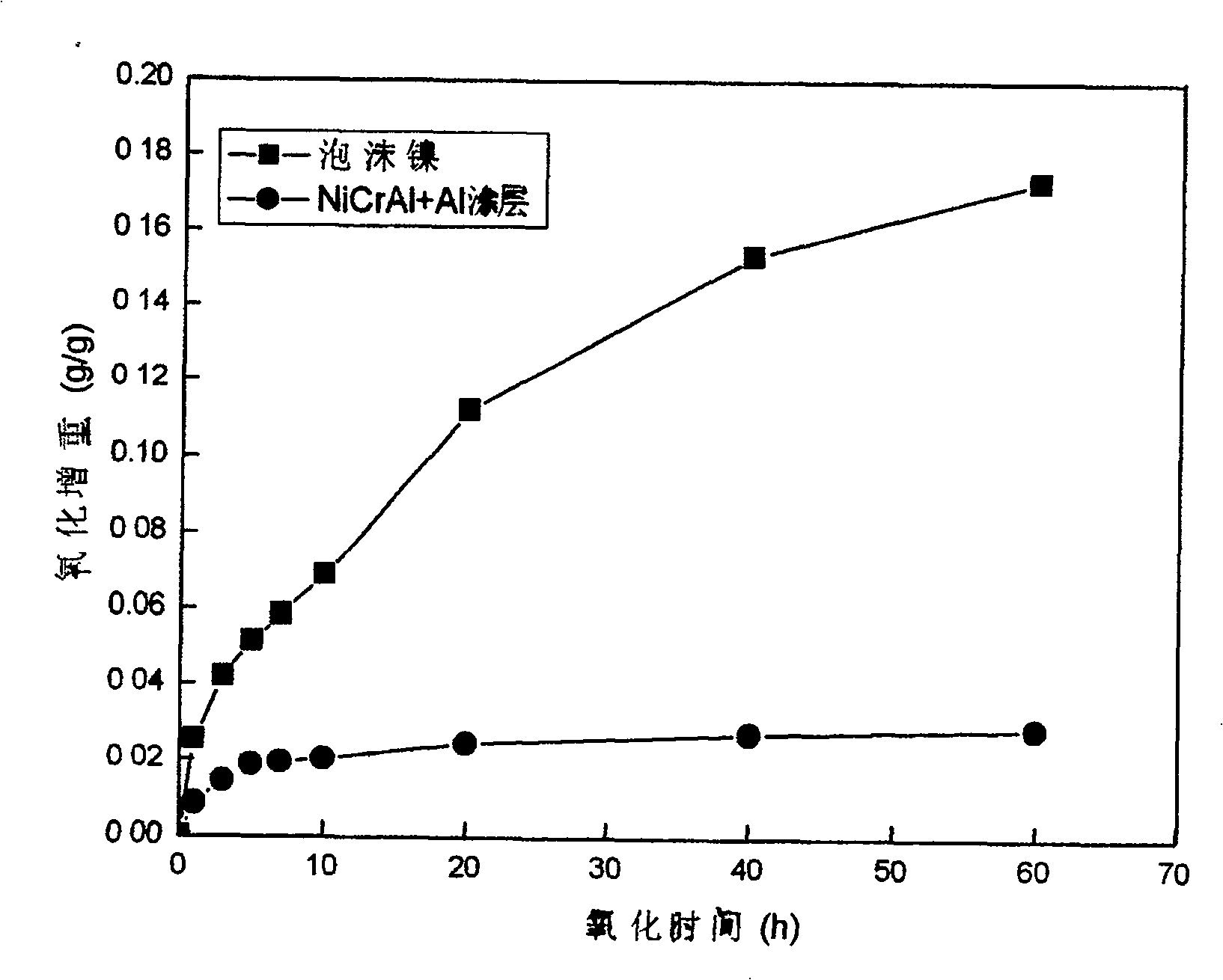

A technology of anti-high temperature oxidation and electrophoretic co-deposition, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of complex equipment, complex heat treatment, and complicated follow-up treatment of electrophoretic deposition layer, so as to improve the density The effects of high temperature resistance, compact packing and excellent high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] A uniform and dense NiCrAl-Al anti-high temperature oxidation mixed coating was prepared on nickel foam (30ppi).

[0029] 1) Electrophoretic deposition of mixed powder: put 5g of (NiCrAl+10wt%Al) mixed powder into 100ml of absolute ethanol, and ball mill for 1h. After ball milling, add 0.24g of AlCl 3 ·6H 2 O, and ultrasonically treat the prepared suspension for 10 min to disperse it evenly. Finally, it is connected to the deposition circuit (the structure of two anodes and one cathode can be used to ensure that the coating fully covers the foamed nickel substrate). The anode is stainless steel, the cathode is nickel foam, and the working area is 5cm 2 , Depositing at a voltage of 100V / cm for 8 minutes (while stirring) can obtain a uniform coating that fully covers the foamed nickel.

[0030] 2) The deposited coating is dried in the air for 24 hours, and then placed in a vacuum furnace for heat treatment at 1000° C. for 2 hours. Remove from oven when cool.

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com