Nanoparticle-carbon dots@silica composite nanoparticle with long afterglow luminescence, long afterglow material and preparation method

A composite nanoparticle, long afterglow luminescence technology, applied in the field of 3D printing materials, can solve the problems of few types and high process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of carbon dots@silica composite nanoparticles with long afterglow luminescence properties includes the following steps:

[0054] (1) Preparation of carbon dot materials:

[0055] Step 1: Add 16 mL of deionized water to the jar, add a clean magnetic stirrer, slowly add 4 mL of ethanolamine with stirring, and then add 8 mL of phosphoric acid dropwise.

[0056] Step 2: After the solution is cooled, take out the stirring magnet, transfer the solution to a polytetrafluoroethylene reaction kettle, and react for 5-6 minutes under microwave reaction conditions with a power of 700-750W.

[0057] Step 3: After the solution is cooled, add 40 mL of deionized water, and disperse evenly under an ultrasonic cleaner.

[0058] Step 4: After the suspension is adjusted to pH=7 with sodium bicarbonate, centrifuge at 12000-15000rpm for 10min, collect the supernatant, and filter it with a 0.22μm water-based membrane filter while retaining the carbon black The precipi...

Embodiment 1

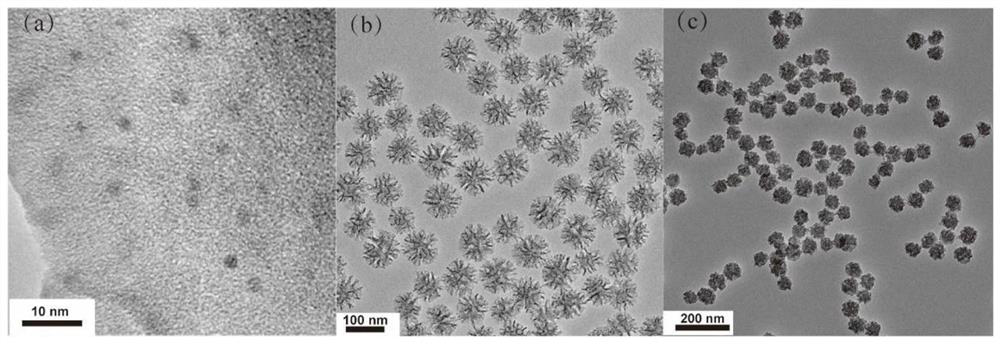

[0075] Example 1 Morphology characterization of carbon dots, mesoporous silica and carbon dots@silica composite nanoparticles used in the present invention

[0076] The carbon dots were prepared by microwave method. Mesoporous silica nanoparticles and carbon dot silica nanoparticles were uniformly dispersed in anhydrous ethanol solution and placed on a 200 mesh copper plate with a diameter of 3 mm for transmission electron microscopy (HITACHI HT7800, Japan) scanning photography. TEM image analysis results showed that the purified CDs had a quasi-spherical morphology with an average particle size of 2.5 nm. The unencapsulated mesoporous silica showed monodisperse spheres, and the mesoporous morphology of Cdots@silica composite nanoparticles obtained by encapsulating Cdots by hydrothermal reaction disappeared, but still had monodisperse properties.

Embodiment 2

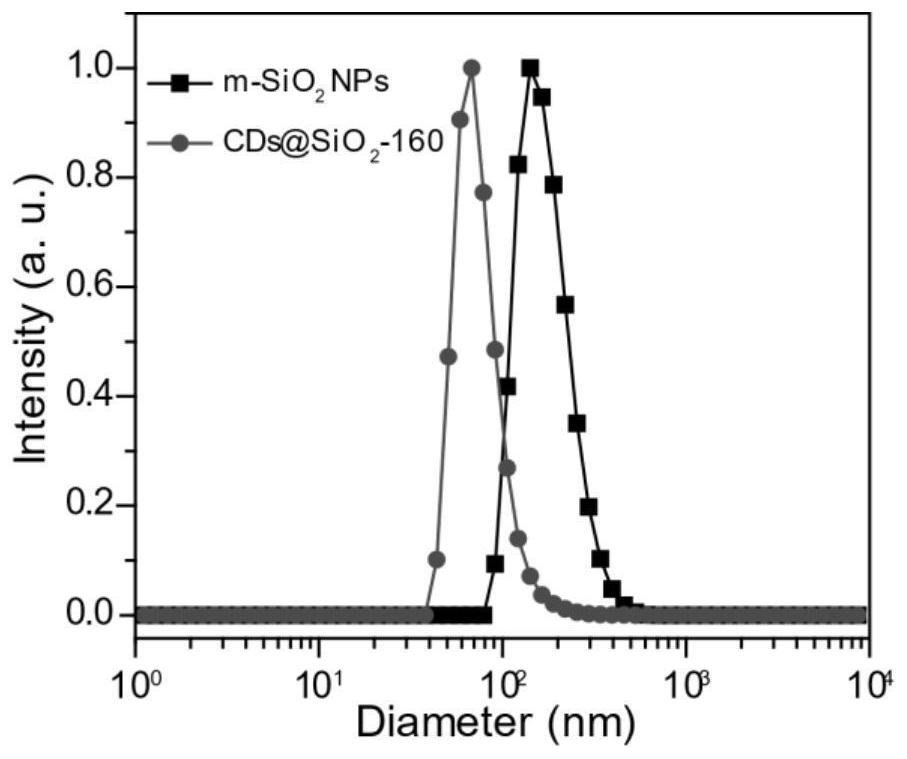

[0077] Example 2 Particle size comparison of mesoporous silica and carbon dots@silica composite nanoparticles.

[0078] The particle size of mesoporous silica nanoparticles and carbon dots@silica composite nanoparticles was determined by dynamic light scattering (DLS nanoparticle size analyzer). Compared with mesoporous silica nanoparticles, the particle size of carbon dots@silica nanoparticles is reduced, indicating that the mesoporous structure collapses when mesoporous silica is encapsulated with carbon dots under hydrothermal conditions, resulting in particle size reduction. Small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com